loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

starlite frp vessel

The Innovative World of Starlite FRP Vessels

In recent years, the industrial landscape has witnessed a significant transformation, particularly in the realm of construction materials. Among the most groundbreaking innovations is the advent of Starlite Fiber Reinforced Polymer (FRP) vessels. This technology has emerged as a leading solution in various sectors, including marine, chemical processing, and storage systems, revolutionizing how we think about durability, weight, and sustainability.

Understanding FRP Technology

Fiber Reinforced Polymer (FRP) is a composite material made from a polymer matrix reinforced with fibers. These fibers, typically made from materials such as glass, carbon, or aramid, provide exceptional strength-to-weight ratios. The combination of lightweight polymers and robust fibers results in a material that is not only strong and resilient but also resistant to corrosion, making it ideal for a variety of challenging environments.

Starlite FRP vessels harness this technology, offering significant advantages over traditional materials like metal and concrete. One of the primary benefits is their resistance to a wide range of chemicals, making them particularly suitable for industries dealing with aggressive substances. Additionally, Starlite FRP vessels are impervious to rust, which extends their lifespan and reduces maintenance costs.

Key Benefits of Starlite FRP Vessels

1. Lightweight One of the pivotal attributes of Starlite FRP vessels is their lightweight nature. Weighing substantially less than their metal counterparts, these vessels reduce transportation costs and ease installation. This is particularly beneficial in scenarios where lifting equipment is limited or where structural support is a concern.

2. Corrosion Resistance Corrosion remains a significant challenge in many industries, leading to increased maintenance and replacement costs. Starlite FRP's inherent resistance to corrosive agents allows for longer operational lifespans and reduced downtime, translating to substantial cost savings in the long run.

3. Thermal Insulation Starlite FRP vessels also exhibit excellent thermal insulation properties. This characteristic makes them suitable for applications requiring temperature control, ensuring that the contents maintain their desired thermal state while minimizing energy consumption.

starlite frp vessel

4. Customization The manufacturing process of FRP vessels allows for considerable customization. Manufacturers can tailor the shapes, sizes, and color schemes to meet specific client requirements. This flexibility is a game-changer for industries that often need specialized storage solutions.

5. Environmental Friendliness With a growing emphasis on sustainability, Starlite FRP vessels stand out due to their reduced environmental impact. The materials used in their production can often be sourced sustainably, and the vessels themselves can be designed for recyclability at the end of their life cycle.

Applications of Starlite FRP Vessels

Starlite FRP vessels are utilized across a diverse array of industries. In the chemical processing sector, these vessels are perfect for storing and transporting aggressive chemicals without the risk of leakage or degradation. The marine industry benefits from their lightweight nature and resistance to seawater, making them ideal for boat manufacturing and storage solutions.

In the food and beverage industry, Starlite FRP vessels are employed for their ease of cleaning and resistance to contaminants. By ensuring that products remain uncontaminated, they help maintain the highest industry standards for safety and quality.

Moreover, with the escalating focus on environmental sustainability, renewable energy sectors are increasingly adopting Starlite FRP vessels for specific applications, providing robust solutions without the ecological footprint associated with traditional materials.

Conclusion

The emergence of Starlite FRP vessels marks a substantial shift towards more innovative, efficient, and environmentally friendly materials in various industries. Their lightweight, corrosion-resistant, and customizable nature positions them at the forefront of modern technology. As industries continue to evolve and demand more from their materials, Starlite FRP vessels represent a promising pathway towards enhanced performance and sustainability in the engineered world. With ongoing advancements in composite technologies, the future looks bright for Starlite FRP vessels and their applications across multiple sectors.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

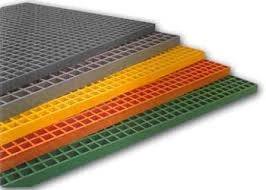

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025