loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

starlite frp vessel

Understanding Starlite FRP Vessels Revolutionizing Industry Applications

In recent years, the industrial sector has seen significant advancements in material technology, leading to the development of innovative solutions that enhance efficiency and sustainability. One such breakthrough is the Starlite FRP (Fiber Reinforced Polymer) vessel, a game-changer in various applications ranging from chemical storage to maritime engineering. This article delves into the composition, advantages, applications, and future of Starlite FRP vessels.

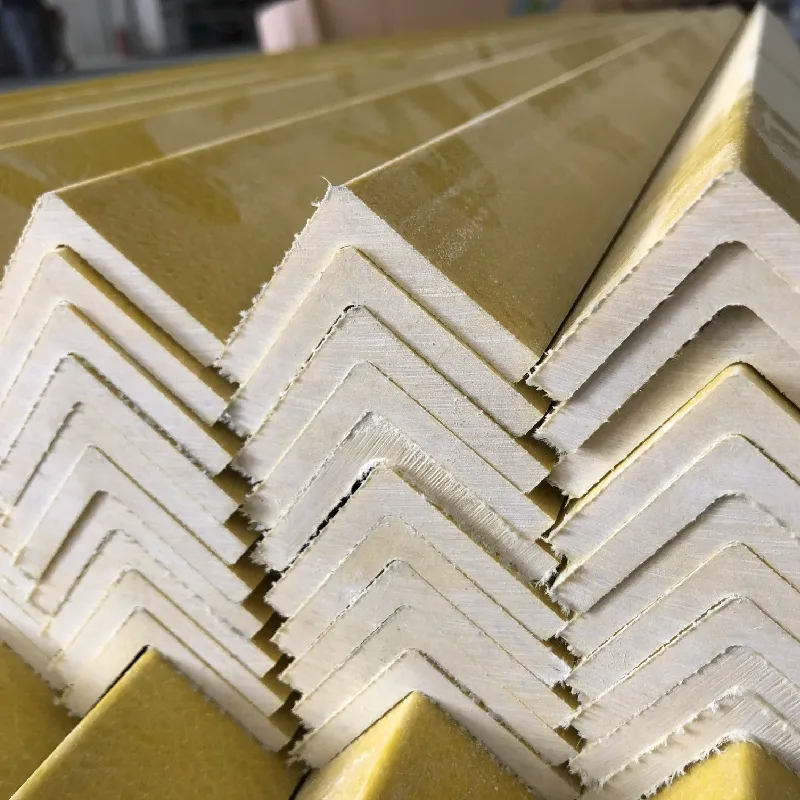

Composition of Starlite FRP Vessels

Starlite FRP vessels are primarily made from a composite material consisting of a polymer matrix reinforced with fibers, typically glass or carbon. The polymer base provides outstanding corrosion resistance, while the reinforcing fibers enhance the strength and stiffness of the structure. This combination not only makes the vessels lightweight but also allows them to withstand extreme environmental conditions, making them suitable for both industrial and marine applications.

Advantages of Starlite FRP Vessels

One of the primary benefits of Starlite FRP vessels is their exceptional durability. Unlike traditional materials such as metal or concrete, FRP vessels do not corrode, which is particularly valuable in industries that deal with aggressive chemicals and challenging environments. This property significantly extends the lifecycle of the vessel, reducing the need for frequent replacements and repairs.

Additionally, the lightweight nature of FRP vessels contributes to lower shipping and handling costs. The reduced weight also minimizes structural support requirements, leading to cost-effective installation solutions. Furthermore, the versatility of FRP allows for customized designs, which can be tailored to meet specific client needs and operational conditions.

Another significant advantage is the thermal insulation properties of Starlite FRP vessels. These vessels can maintain stable internal temperatures, making them suitable for applications that require stringent thermal controls, such as in the pharmaceutical and food processing industries.

starlite frp vessel

Applications of Starlite FRP Vessels

The applications of Starlite FRP vessels are vast and varied. In the chemical industry, they are used for storing corrosive substances, including acids, bases, and solvents. Their resistance to chemicals ensures that the integrity of both the vessel and the stored materials is maintained, which is crucial for safety and compliance with regulatory standards.

In the water treatment sector, FRP vessels are employed for both storage and processing purposes. Their corrosion resistance makes them ideal for housing chemicals necessary for water purification, as well as for storing treated water. Additionally, FRP vessels are increasingly used in the oil and gas industry, providing secure storage solutions for various drilling fluids and chemicals.

Maritime applications are another significant area for Starlite FRP vessels. The marine industry requires materials that can endure harsh saltwater conditions, and FRP's resistance to corrosion makes it an ideal choice for fabricating components such as tanks, boat hulls, and offshore structures. The lightweight nature of FRP also enhances fuel efficiency in vessels, contributing to more sustainable maritime practices.

The Future of Starlite FRP Vessels

As industries continue to focus on sustainability and efficiency, the role of advanced materials like Starlite FRP is on the rise. Continuous research and development are expected to improve the performance of FRP vessels, including increasing the range of available fibers and resins, enhancing their mechanical properties, and exploring eco-friendly manufacturing processes.

Moreover, as regulations around material use and waste management become stricter, the adoption of Starlite FRP vessels will likely continue to grow. The potential for recycling and repurposing FRP materials presents an opportunity for reducing environmental impact, thus aligning with global sustainability goals.

In conclusion, Starlite FRP vessels represent a significant advancement in material engineering, offering numerous benefits that propel their use across various industries. Their unique properties not only enhance operational efficiency but also contribute to a safer and more sustainable industrial landscape. As technology continues to evolve, the future for Starlite FRP vessels looks promising, ensuring their place at the forefront of material innovation.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025