loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

smc panel tank

Understanding SMC Panel Tanks An Overview

In recent years, the demand for efficient water storage solutions has surged, especially in industries where water is critical to processes and operations. Among various technologies available, SMC (Sheet Molding Compound) panel tanks have gained substantial attention due to their unique features and advantages.

What is an SMC Panel Tank?

SMC panel tanks are constructed from a composite material that combines resin and glass fiber, resulting in a lightweight yet durable solution for water storage. These tanks are made using advanced molding techniques, leading to a structure that can resist corrosion, high temperatures, and UV radiation. As a result, SMC panel tanks are not only functional but also environmentally friendly, with a design that minimizes the impact of pollutants.

Features and Benefits

1. Durability and Strength One of the standout qualities of SMC panel tanks is their robustness. Unlike traditional tanks made of steel or concrete that can succumb to rust and cracks, SMC panels resist environmental wear and tear, which significantly extends the lifespan of the tank.

2. Lightweight Design The lightweight nature of SMC materials makes installation much easier compared to heavier options. This attribute allows for efficient transportation and reduces the structural load on the supporting base, making it suitable for various installation sites.

3. Corrosion Resistance SMC panel tanks are inherently resistant to corrosion, which is a critical factor in water storage. This characteristic ensures that the water quality remains uncompromised and eliminates the need for frequent maintenance or replacement that is often associated with traditional materials.

4. Customizable Size and Shape SMC panel tanks can be customized to meet specific storage requirements. Manufacturers can create tanks of varying sizes and shapes, making them versatile for industrial, agricultural, and municipal applications.

smc panel tank

5. Cost-Effectiveness While the initial investment in SMC technology might be higher than basic alternatives, the long-term savings in maintenance, durability, and lifespan often outweigh the costs. Moreover, the quick and easy installation process reduces labor costs, which adds to the economic advantages.

Applications of SMC Panel Tanks

SMC panel tanks are utilized across multiple sectors, including

- Water Supply Municipalities use these tanks to store potable water, ensuring a reliable supply to residents. - Industrial Use Factories and industrial plants deploy SMC panel tanks for processes that require substantial amounts of water, from cooling systems to storage for raw materials. - Agricultural Storage Farmers incorporate SMC tanks for irrigation and livestock needs, efficiently managing water resources. - Fire Protection SMC panel tanks serve as storage solutions for firefighting systems, guaranteeing immediate access to water during emergencies.

Environmental Considerations

As sustainability becomes a pivotal concern worldwide, SMC panel tanks contribute positively to environmental protection. Their longevity means fewer resources are consumed in manufacturing replacements, and their resistance to contamination ensures that the water stored remains clean, reducing the environmental impact associated with water quality degradation.

Conclusion

In conclusion, SMC panel tanks present an innovative solution for water storage challenges faced by various industries. Their durability, lightweight nature, corrosion resistance, and adaptability make them a preferred choice. Investing in SMC technology not only addresses current water storage needs but also promotes sustainable practices, paving the way for a future where water management is efficient and environmentally sound. As this technology continues to evolve, it is likely that SMC panel tanks will play an increasing role in our efforts to meet the world’s growing water demands.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

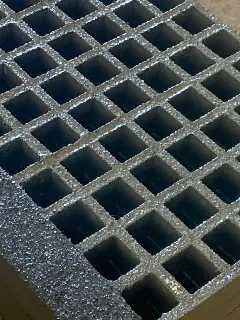

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025