loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Secure Covered Grating: Durable, Anti-Slip FRP Grating Solutions

Covered grating is a key solution in the manufacturing industry, specifically within Manufacturing of building materials and other building components and Manufacturing of non-metallic structural components for construction. This article explores how Zhaojia Composites Co., Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Covered Grating Overview

- Benefits & Use Cases of FRP Covered Grating in Manufacturing of non-metallic structural components for construction

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in Manufacturing

- Conclusion on Covered Grating from Zhaojia Composites Co., Ltd

Covered Grating Overview

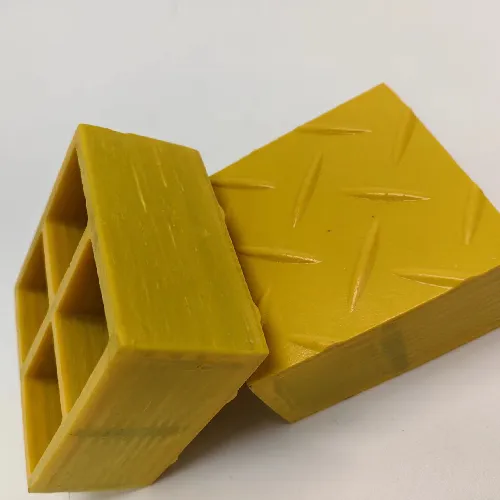

In the demanding world of manufacturing, particularly within the sectors of building materials and non-metallic structural components, reliable and safe flooring solutions are paramount. This is where covered grating emerges as an indispensable product. Essentially, FRP (Fiber Reinforced Polymer) covered grating consists of a standard FRP grating panel with a solid top surface, offering enhanced protection and an impermeable barrier. This unique design prevents liquids, debris, and fumes from passing through, making it ideal for environments requiring strict hygiene or containment. The technical advantages are significant: exceptional corrosion resistance to chemicals, superior slip resistance, and a high strength-to-weight ratio. Unlike traditional metallic options, FRP covered grating does not rust, conduct electricity, or require frequent painting, ensuring long-term performance in corrosive or sensitive areas. Zhaojia Composites Co., Ltd stands as a reliable FRP grating manufacturer, providing cutting-edge solutions that meet stringent industrial standards.

Benefits & Use Cases of FRP Covered Grating in Manufacturing of non-metallic structural components for construction

The applications for covered grating are particularly beneficial within the Manufacturing of non-metallic structural components for construction. Facilities producing fiberglass rebar, composite panels, or advanced insulation materials often deal with chemicals, fine powders, or require clean room conditions. A grating cover from Zhaojia Composites Co., Ltd provides an enclosed walking surface, preventing potential contamination from below and protecting personnel from splashes or falling objects. Key features include its lightweight nature, simplifying installation, and its inherent fire retardant properties, enhancing facility safety. The competitive advantage lies in its unparalleled resistance to aggressive chemicals and extreme temperatures, ensuring a longer lifespan and safer working conditions compared to steel or aluminum. Zhaojia Composites Co., Ltd’s expertise in developing specialized FRP products means our covered grating solutions are engineered to withstand the unique challenges of manufacturing non-metallic structural components, guaranteeing durability and compliance with safety regulations.

Cost, Maintenance & User Experience

When B2B decision-makers in the Manufacturing of building materials and other building components evaluate infrastructure investments, total cost of ownership (TCO) is a critical factor. While the initial investment for covered grating from a reputable FRP grating manufacturer like Zhaojia Composites Co., Ltd might be comparable to, or slightly higher than, traditional materials, the long-term ROI is exceptional. FRP grating boasts remarkable durability, resisting corrosion, impact, and fatigue far better than steel in many industrial environments. This significantly reduces maintenance costs and downtime typically associated with repairs, painting, and replacements. Customers in the building materials sector consistently report extended service life and minimal upkeep requirements. The user experience is also greatly enhanced: the non-conductive nature of FRP improves safety, while the slip-resistant surface reduces accident risks. For businesses aiming for operational efficiency and worker safety, investing in Zhaojia Composites’ high-quality grating cover solutions translates into tangible savings and a safer, more productive work environment.

Sustainability & Market Trends in Manufacturing

The manufacturing landscape is increasingly shaped by sustainability concerns, regulatory pressures, and a drive towards more efficient, eco-friendly materials. FRP covered grating aligns perfectly with these evolving market trends. Its exceptional longevity means fewer replacements and a reduced consumption of raw materials over time, minimizing environmental impact. The manufacturing process for FRP often has a lower carbon footprint compared to producing and maintaining steel alternatives, especially when considering the energy saved on transportation due to its lightweight properties. Regulations pushing for improved workplace safety and reduced environmental emissions further bolster the demand for non-corrosive, non-toxic, and fire-retardant materials like FRP. As a forward-thinking FRP grating manufacturer, Zhaojia Composites Co., Ltd is committed to innovation that supports both operational excellence and environmental stewardship. We offer solutions that not only enhance facility performance but also contribute to a greener, more sustainable future in manufacturing.

Conclusion on Covered Grating from Zhaojia Composites Co., Ltd

In conclusion, FRP covered grating represents a superior choice for businesses in manufacturing, particularly those involved in building materials and non-metallic structural components. Its unmatched durability, corrosion resistance, safety features, and low maintenance requirements make it a highly valuable asset, ensuring long-term ROI and operational efficiency. Zhaojia Composites Co., Ltd, as an industry-leading FRP grating manufacturer, is dedicated to providing high-quality, sustainable grating solutions tailored to the diverse needs of modern industry. We invite B2B decision-makers to discover how our advanced grating cover products can elevate safety, performance, and sustainability within your operations.

Contact us: email: admin@zjcomposites.com

Visit our website: https://www.zjcomposites.com

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025