loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

sectional tanks

Understanding Sectional Tanks A Comprehensive Overview

Sectional tanks are an essential component in various industries that manage the storage and transportation of liquids. These tanks are designed to be assembled from multiple sections, offering versatility and adaptability in different settings. Their construction allows for easy transport, efficiency in space management, and customization according to specific storage needs.

One of the primary benefits of sectional tanks is their modular design. Since they are built from separable sections, these tanks can be assembled on-site, which is particularly advantageous for areas with limited access or where space is at a premium. This feature makes sectional tanks ideal for urban environments or remote locations where transporting a fully assembled unit would be challenging or costly. Moreover, sectional tanks can be expanded by adding more sections, allowing for scalability without the need for complete replacement, thus providing a long-term solution for growing businesses.

The materials used to construct sectional tanks are typically resilient and corrosion-resistant, which plays a vital role in longevity and performance. Common materials include carbon steel, stainless steel, and polymer, each chosen based on the nature of the liquid being stored. For instance, stainless steel is often preferred for chemicals or food-grade liquids due to its non-reactive properties, while carbon steel might be suitable for industrial applications. The choice of material often corresponds to the specific requirements of the industry, including factors such as temperature regulation, pressure retention, and chemical compatibility.

sectional tanks

In terms of design, sectional tanks can be customized to fit unique specifications. This design flexibility allows for variations in size, shape, and orientation, depending on the storage capacity and environmental constraints. Many sectional tanks also come with integrated features such as access ports, vents, and gauges, which facilitate ease of use and monitoring. Such features enhance operational efficiency and ensure compliance with safety regulations, making them ideal for industries such as water treatment, agriculture, and chemical processing.

Furthermore, sectional tanks provide a straightforward installation process that reduces downtime during setup. The sections can be transported separately, minimizing logistical challenges and costs. On installation, the tanks can be rapidly assembled and put into operation, allowing businesses to optimize productivity without extensive delays. This quick deployment is especially beneficial for temporary projects or emergency situations where immediate storage solutions are required.

Maintenance of sectional tanks is also typically less complicated than that of traditional single-piece tanks. The segmented nature of the design allows for easy access to individual sections for cleaning, inspection, or repairs, ensuring that any potential issues can be quickly addressed without compromising the entire system. Regular maintenance is crucial in preventing leaks and ensuring the integrity of the tank, especially in industries where safety is paramount.

In conclusion, sectional tanks represent a practical and efficient solution for liquid storage needs across various sectors. With their modular design, material resilience, customization options, and ease of installation and maintenance, these tanks provide businesses with the flexibility and reliability they require. As industries continue to evolve, the relevance of sectional tanks will likely increase, solidifying their place as a cornerstone in modern liquid storage solutions. Whether for large-scale industrial operations or smaller agricultural applications, sectional tanks cater to diverse requirements, ensuring effective management and safe storage of valuable liquids.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

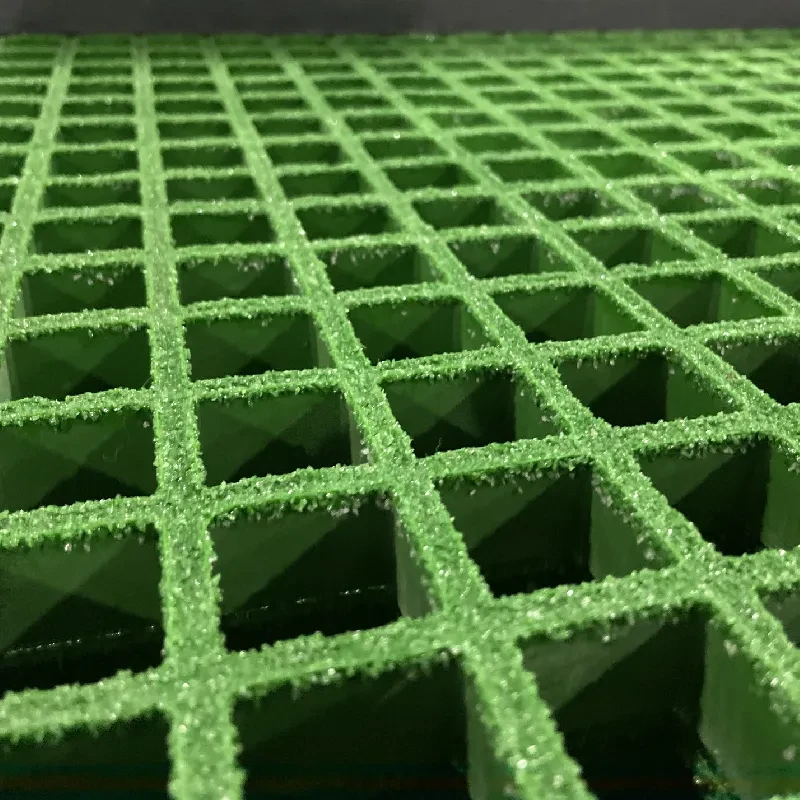

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025