loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Innovative Designs and Applications of FRP Vessels in Modern Industries

The Significance of Reinforced Plastic Vessels in Modern Engineering

Reinforced plastic (RP) vessels, commonly referred to as FRP (Fiberglass Reinforced Plastic) vessels, have become increasingly prominent in various industrial applications. These composite structures have garnered attention for their unique properties, which provide significant advantages over traditional materials such as steel and aluminum. The rise in the use of FRP vessels can be attributed to a confluence of factors, including their strength-to-weight ratio, resistance to corrosion, and overall cost-effectiveness.

Understanding FRP Vessels

FRP vessels are made by combining high-strength fibers, often glass or carbon, with a polymer matrix. The fibers provide reinforcement, while the polymer offers protection against environmental factors. This composition results in vessels that are not only lightweight but also incredibly strong, allowing them to withstand high pressures and temperatures without significant deformation or failure.

The manufacturing process for FRP vessels typically involves techniques like hand lay-up, filament winding, or resin transfer molding. Each method has its own set of advantages and is chosen based on specific application requirements. For instance, filament winding is particularly effective for creating high-strength cylinders, making it a popular choice for pressure vessels.

Advantages of FRP Vessels

1. Corrosion Resistance One of the standout features of FRP vessels is their resistance to corrosion. Unlike metal vessels, which can rust and degrade when exposed to harsh chemicals or moisture, FRP can withstand such conditions, making it an ideal choice for the chemical, oil and gas, and waste management industries.

2. Lightweight The low density of FRP materials means that vessels can be constructed to hold the same volume as their metallic counterparts while being significantly lighter. This weight reduction not only enhances ease of installation but also decreases transportation costs.

ro frp vessel

3. Thermal Insulation FRP has excellent thermal insulation properties. This feature helps maintain the temperature of the contents held within the vessel, which is critical in applications such as food storage or chemical processing. The ability to retain heat or cold can lead to improved efficiency and reduced energy costs.

4. Cost-Effectiveness While the initial investment in FRP vessels might be higher than some traditional materials, the long-term savings associated with maintenance, durability, and operational efficiency often lead to a lower overall cost of ownership. The longevity of FRP vessels also contributes to reducing the frequency of replacements.

5. Customizability FRP vessels can be tailored to meet specific needs, from size and shape to mechanical properties. This flexibility allows engineers to design solutions that precisely fit the requirements of their projects.

Applications in Industry

The use of FRP vessels spans across numerous industries. In the water treatment sector, they are used for storage tanks and pressure vessels due to their resistance to corrosion. The aerospace industry benefits from their lightweight nature, which helps to improve fuel efficiency. Additionally, FRP vessels are integral to the renewable energy field, particularly in wind turbine construction where reducing weight is critical.

Conclusion

As industries continue to seek out durable, lightweight, and cost-effective solutions, FRP vessels will undoubtedly play a vital role in future engineering projects. Their unique properties not only enhance performance but also contribute to a more sustainable approach to industrial designs. Embracing the use of FRP vessels will allow companies to innovate and improve efficiency across a wide range of applications.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

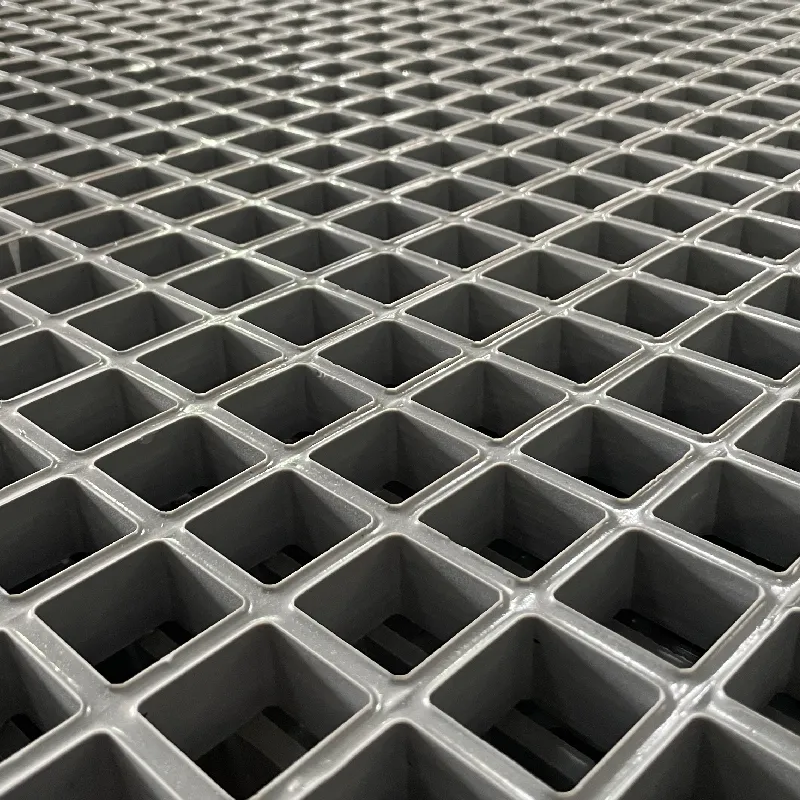

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025