loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

ro frp vessel

Understanding the Benefits of Reinforced Plastic Vessels (FRP)

Fiber Reinforced Plastic (FRP) vessels have emerged as a significant innovation in the field of material science and engineering. These vessels, constructed from a combination of fiber materials and resin, offer unique properties that make them suitable for a wide range of applications, particularly in industries such as chemical processing, water treatment, and storage.

Understanding the Benefits of Reinforced Plastic Vessels (FRP)

Moreover, FRP vessels exhibit exceptional resistance to corrosion. In environments where chemical exposure is common, traditional materials often suffer degradation over time. In contrast, FRP vessels can withstand harsh chemicals, extreme temperatures, and various environmental factors, ensuring longevity and reliability. This resistance to corrosion minimizes the need for frequent replacements, leading to substantial cost savings for businesses over time.

ro frp vessel

Additionally, FRP vessels can be manufactured in a variety of shapes and sizes, allowing for greater design flexibility. Whether the need is for storage tanks, pressure vessels, or custom-shaped containers, FRP can be molded to meet specific requirements. This versatility makes them an attractive option for industries that have varied and specific needs.

The insulating properties of FRP are also worth noting. These vessels can help maintain the temperature of stored materials, which is especially important in applications involving thermal-sensitive substances. The thermal insulating capability of FRP contributes to energy efficiency, as it minimizes heat transfer, thus reducing energy costs associated with heating or cooling processes.

Lastly, the environmental impact of using FRP vessels is an important consideration. Being made from recyclable materials, FRP vessels encourage sustainability. Their long lifespan, combined with their ability to be repurposed at the end of their life cycle, aligns with the increasing demand for eco-friendly practices in industrial operations.

In conclusion, the adoption of FRP vessels presents numerous advantages, including reduced weight, enhanced corrosion resistance, design flexibility, excellent insulation properties, and eco-friendliness. As industries continue to innovate and seek more efficient, sustainable solutions, FRP vessels are poised to play a crucial role in the future of material engineering.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

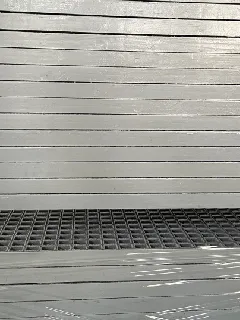

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025