loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

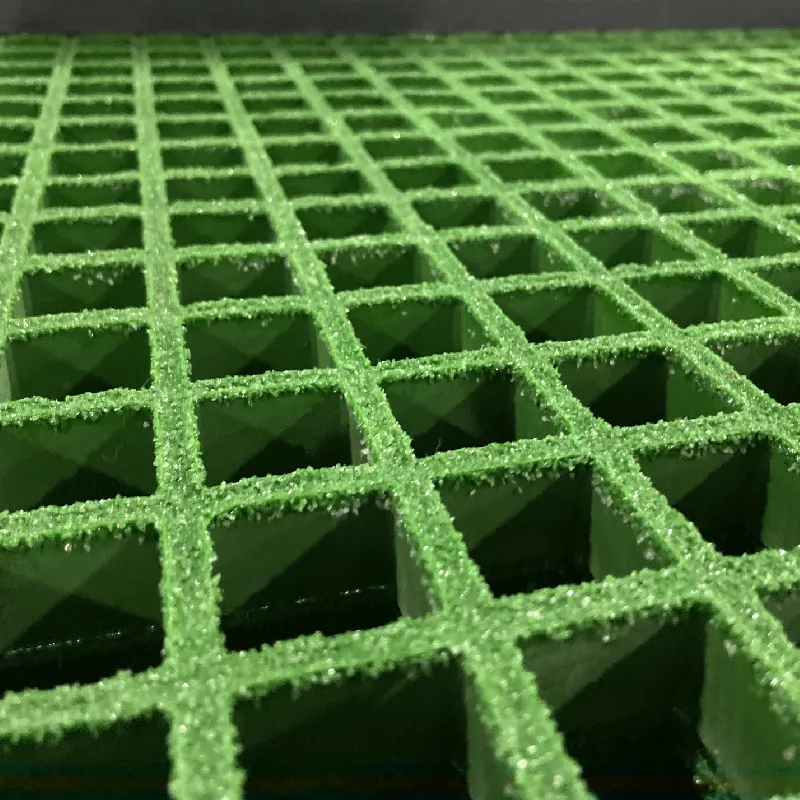

pultruded frp grating

Pultruded FRP Grating A Comprehensive Overview

In recent years, pultruded fiber-reinforced plastic (FRP) grating has gained significant traction across various industries due to its superior performance attributes when compared to traditional materials. This innovative material combines the strengths of fiberglass with resin in a specialized manufacturing process known as pultrusion. As a result, pultruded FRP grating offers an array of benefits, making it a preferred choice for many applications.

Manufacturing Process of Pultruded FRP Grating

The pultrusion process involves the continuous pulling of fibers through a resin bath, followed by heating and curing in a die. This method ensures uniformity in both strength and composition, allowing for the production of various profiles that can be adapted for specific applications. The resulting grating is lightweight yet exceptionally strong, making it an optimal solution for areas requiring durable flooring materials.

Key Benefits of Pultruded FRP Grating

1. Corrosion Resistance One of the most compelling advantages of pultruded FRP grating is its resistance to corrosion. Unlike traditional steel or aluminum grating, which can rust and deteriorate over time when exposed to harsh environments, FRP is inert and withstands chemicals, moisture, and UV radiation. This quality significantly reduces maintenance costs and extends the lifespan of the material.

2. Lightweight and High Strength Pultruded FRP grating is remarkably lightweight, making it easier to handle and install. Despite its low weight, it maintains a high strength-to-weight ratio, allowing it to support heavy loads without compromising structural integrity. This characteristic is particularly beneficial in applications where weight is a critical factor, such as in aerospace and automotive industries.

pultruded frp grating

3. Safety and Slip Resistance Safety is a primary concern in many industrial applications, and pultruded FRP grating excels in this regard. The surface of the grating can be designed to provide excellent slip resistance, minimizing the risk of accidents in wet or oily conditions. Additionally, the non-conductive nature of FRP makes it an ideal choice for electrical installations, reducing the risk of electric shock.

4. Versatility Pultruded FRP grating can be engineered to meet specific load requirements and can be manufactured in various colors and configurations. This versatility allows it to be used in a wide range of applications, including walkways, platforms, stair treads, and even architectural features.

5. Environmental Impact The use of pultruded FRP grating contributes to sustainability efforts. Its long lifespan means less frequent replacement, and when it does reach the end of its useful life, FRP can be recycled, further reducing its environmental footprint.

Applications of Pultruded FRP Grating

Due to its numerous advantages, pultruded FRP grating is widely utilized in various sectors. In the chemical and petrochemical industries, it is employed for flooring and platforms where exposure to corrosive substances is common. Infrastructure projects, such as bridges and walkways, also benefit from the lightweight and strong nature of FRP grating. Additionally, the food processing industry favors FRP due to its ease of cleaning and hygienic properties.

In conclusion, pultruded FRP grating emerges as a versatile and reliable solution for modern industrial challenges. Its unique benefits of corrosion resistance, lightweight strength, safety features, and environmental sustainability make it a material of choice across myriad applications. As industries continue to seek innovative solutions, pultruded FRP grating stands out as a testament to advancements in material science and engineering.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025