loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

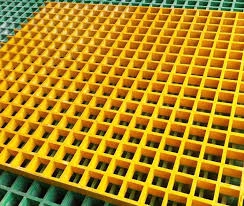

pultruded frp grating

Understanding Pultruded FRP Grating A Comprehensive Overview

Pultruded FRP (Fiber Reinforced Polymer) grating is an innovative and versatile building material that has gained significant attention in various industries, including construction, marine, chemical processing, and wastewater treatment. This unique product combines the advantages of fiberglass with a pultrusion process, resulting in a strong, lightweight, and corrosion-resistant material that is ideal for diverse applications.

What is Pultruded FRP Grating?

Pultrusion is a manufacturing process that involves drawing fibers through a resin bath and then through a heated die, which forms the material into a specific shape. The result is a continuous length of fibrous material that exhibits superior mechanical properties. Pultruded FRP grating is made by integrating fiberglass reinforcement with a thermosetting resin, typically polyester or vinyl ester, resulting in a structural product that is both robust and lightweight.

The gratings come in various configurations, typically with a mesh-like appearance, allowing for ease of drainage and visibility. The open design also minimizes wind resistance, making it a preferred choice for outdoor installations.

Advantages of Pultruded FRP Grating

1. Corrosion Resistance One of the standout features of pultruded FRP grating is its exceptional resistance to corrosion. Unlike traditional materials like steel, which can rust and weaken over time, FRP does not corrode, making it ideal for harsh environments, such as chemical plants or coastal applications.

2. Lightweight Pultruded FRP grating is significantly lighter than metal grating, making it easier and more economical to transport and install. This lightweight nature does not compromise its strength; in fact, it is often stronger than steel or aluminum, especially in conditions where weight is a concern.

3. High Strength-to-Weight Ratio The integration of fiberglass in the composite structure provides high tensile strength and stiffness, making it suitable for load-bearing applications. The strength-to-weight ratio is particularly beneficial in applications where structural integrity is crucial.

pultruded frp grating

4. Low Maintenance Due to its resistance to chemicals and environmental factors, pultruded FRP grating requires minimal maintenance, reducing long-term operational costs for businesses that utilize it.

5. Non-Conductivity FRP grating is non-metallic, meaning it is non-conductive and does not create a risk of electrical hazards. This property makes it suitable for use in electrical applications or areas where static discharge could be dangerous.

6. Versatility Pultruded FRP grating can be custom-manufactured in various colors and sizes. This adaptability allows it to fit seamlessly into different architectural designs, whether in industrial settings or commercial infrastructures.

Applications of Pultruded FRP Grating

Pultruded FRP grating finds applications in numerous fields, including

- Chemical Processing Its corrosion resistance makes it ideal for walkways and platforms used in chemical plants. - Wastewater Treatment FRP grating is used in treatment plants due to its ability to withstand harsh environmental conditions. - Marine Environments Coastal and marine applications benefit from the material's resilience to saltwater and UV exposure. - Transportation Facilities Airports, train stations, and docks utilize FRP grating for its lightweight yet sturdy properties.

Conclusion

In summary, pultruded FRP grating is a highly functional and effective solution for various industrial and commercial applications. Its combination of strength, lightweight design, and resistance to corrosion and environmental factors positions it as a superior alternative to traditional materials. As industries continue to explore innovative materials to enhance the durability and efficiency of their infrastructures, pultruded FRP grating is likely to play a pivotal role in modern construction and maintenance practices.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025