loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

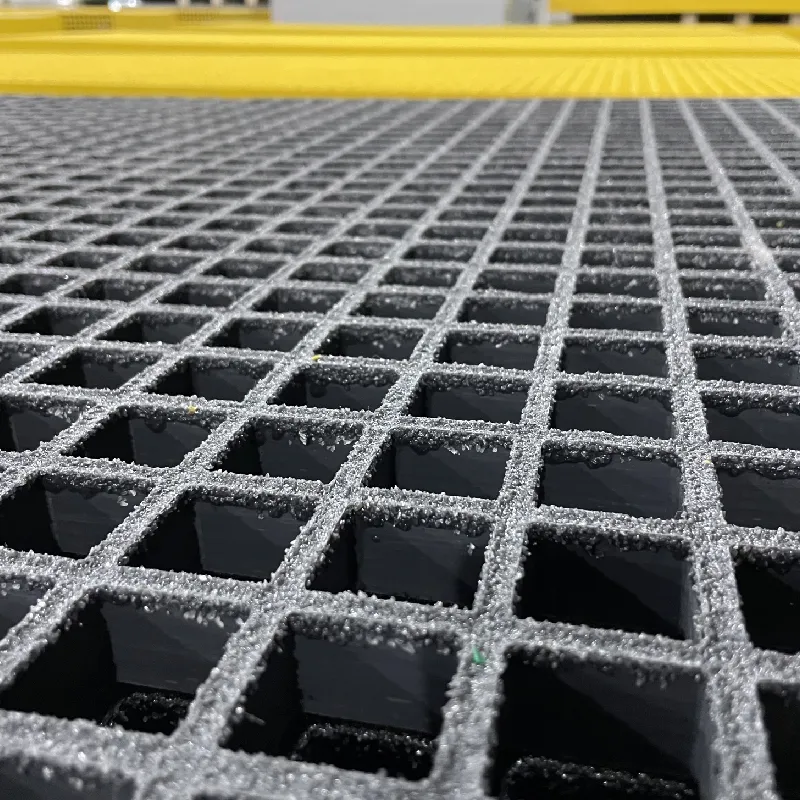

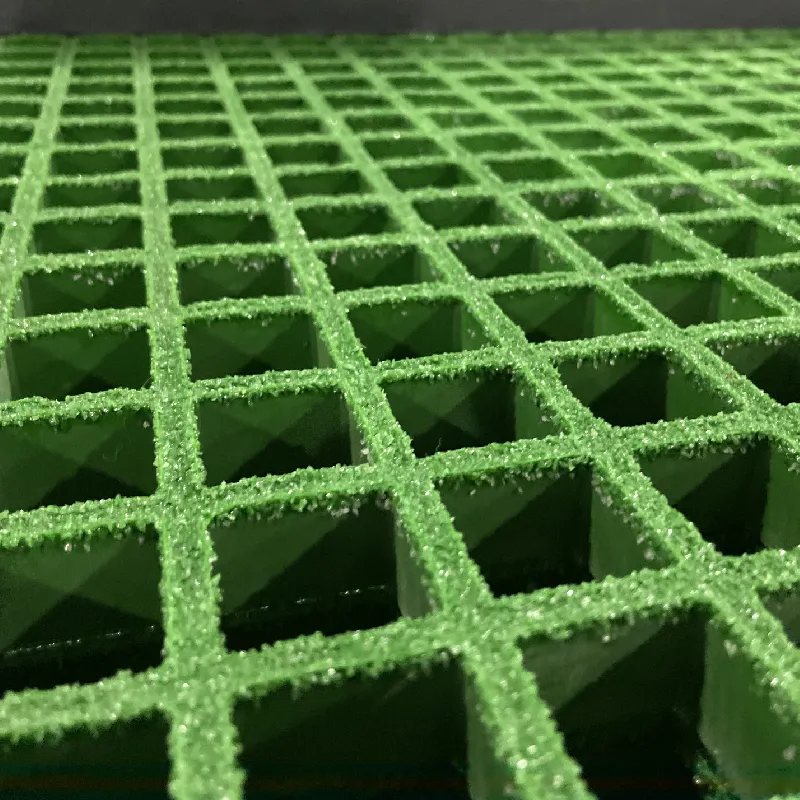

Premium FRP Micro Mesh Grating: Anti-Slip, Safe & Durable Solutions

Unveiling Innovation: Top Fiberglass Grating Manufacturers from China at the Composites Expo

The China Composites Expo stands as a beacon for advanced materials, a global nexus where innovation meets industry. Each year, it draws a vast array of manufacturers, engineers, and B2B decision-makers eager to witness the cutting edge of composite technology. For anyone involved in infrastructure development, industrial safety, or renewable energy, the Expo is more than just a trade show; it's a critical platform for identifying fiberglass grating solutions that promise durability, efficiency, and long-term value.

This premier event offers an unparalleled opportunity to engage with global industry leaders, explore groundbreaking materials, and forge strategic partnerships. Specifically, for the fiberglass grating industry, the Expo highlights the immense potential and advanced capabilities of Chinese manufacturers who are increasingly shaping global standards with their innovative products and sophisticated production techniques. From intricate frp micro mesh grating designs to robust frp platform grating, the showcase of solutions is truly comprehensive, addressing diverse and demanding industrial applications.

It's a testament to the industry's dynamism, where high-performance composites are not just materials but catalysts for safer, more sustainable, and more efficient industrial environments worldwide.

Industry Trend Spotlight: The Ascent of FRP Materials

The global composites market is experiencing an unprecedented surge, driven by an escalating demand for materials that offer superior performance without the traditional drawbacks of steel or concrete. This trend is particularly evident in the realm of Fiberglass Reinforced Plastic (FRP) materials, which are prized for their exceptional durability, lightweight nature, and remarkable corrosion resistance. Industries from infrastructure development and water treatment to renewable energy and chemical processing are increasingly turning to FRP solutions, including various forms of fiberglass grating, to overcome design limitations and enhance operational longevity.

Innovation is not just a buzzword; it's the engine powering this growth. We're seeing significant advancements in smart composites, where materials are imbued with sensors for real-time monitoring, and in advanced manufacturing techniques that allow for greater precision, faster production, and more complex geometries. These innovations are gaining global attention, as they promise not only enhanced product performance but also a reduction in lifecycle costs and environmental impact. The development of specialized gratings like frp micro mesh grating for slip resistance in pedestrian areas and highly resilient frp platform grating for heavy industrial loads exemplifies this commitment to tailored, high-performance solutions.

Market data underscores this robust trajectory: The global composites market is projected to experience substantial growth, propelled by increasing applications across key sectors. Construction, with its persistent need for resilient and low-maintenance materials, is a primary driver. Wind energy, requiring lightweight yet incredibly strong components for turbine blades and access structures, heavily relies on advanced FRP. Transportation, from automotive to marine, benefits from composites' weight-saving properties, contributing to fuel efficiency and reduced emissions. This growth is underpinned by a strong focus on sustainable and high-performance materials, aligning with global environmental objectives and stricter industry standards.

Emerging focus areas include the development of sustainable composite solutions that minimize waste and maximize resource efficiency, and the creation of ultra-high-performance FRP materials designed for the most demanding industrial applications, such as chemical containment or extreme temperature environments. Furthermore, Chinese manufacturers, in particular, are strategically expanding their global market reach, leveraging their advanced production capabilities and competitive pricing to establish strong footholds in international markets. This expansion includes a diverse range of products, from standard frp protruded grating used for excellent bi-directional strength to custom-engineered access solutions.

Profiles of Leading Fiberglass Grating Manufacturers

At the forefront of this dynamic industry are companies that consistently push the boundaries of composite material science and manufacturing excellence. While global players set benchmarks, Chinese manufacturers are rapidly gaining recognition for their innovation, quality, and vast production capacities.

Zhaojia Composites Co., Ltd: A Beacon of Innovation and Quality

Among the most prominent exhibitors at the China Composites Expo and a leader in the fiberglass grating sector is Zhaojia Composites Co., Ltd. With years of dedicated experience, Zhaojia has carved out a reputation for excellence, driven by a relentless commitment to innovation and customer satisfaction. Their extensive product portfolio spans a comprehensive range of FRP composite materials, meticulously engineered to meet the stringent demands of various industries.

Zhaojia's expertise is particularly evident in their diverse offering of fiberglass grating. This includes high-performance frp micro mesh grating, specifically designed for applications requiring superior anti-slip properties and excellent load distribution, making it ideal for pedestrian walkways, wheelchair access ramps, and areas where small objects could fall through standard openings. They also specialize in robust frp platform grating, engineered for heavy industrial environments, offering unparalleled strength-to-weight ratio and resistance to corrosive chemicals, crucial for platforms, trench covers, and work areas in chemical plants, offshore rigs, and manufacturing facilities. Furthermore, their frp protruded grating provides exceptional bi-directional strength and enhanced slip resistance, suitable for high-traffic zones and challenging conditions.

What truly sets Zhaojia Composites apart is their strong focus on customization and rigorous quality control. Recognizing that every industrial application has unique requirements, they work closely with clients to develop tailor-made FRP solutions, ensuring optimal performance and cost-effectiveness. Their manufacturing processes adhere to stringent international quality standards, backed by continuous testing and validation, which guarantees the reliability and longevity of their products. This proven expertise in catering to diverse industrial applications—from chemical processing and marine environments to architectural projects and power generation—makes Zhaojia Composites a trusted partner for B2B decision-makers seeking premium fiberglass grating solutions.

Other Noteworthy Industry Leaders:

- Strongwell: A global leader in pultrusion, Strongwell is renowned for its comprehensive range of FRP products, including high-strength fiberglass grating. Their engineering prowess and commitment to innovation have made them a benchmark for quality in structural composites, particularly for heavy-duty industrial and infrastructure applications.

- Fibergrate Composite Structures Inc.: With a long history in the composites industry, Fibergrate is synonymous with premium fiberglass grating and structural products. They are known for their extensive product lines, robust material formulations, and a strong focus on safety and performance across various challenging environments.

- Nanjing Dehe Composite Materials Co., Ltd: This Chinese manufacturer has rapidly established itself as a reliable provider of high-quality FRP products. Nanjing Dehe focuses on developing cost-effective yet high-performance solutions, including various types of fiberglass grating, meeting both domestic and international market demands with a focus on efficient production and technical support.

Market Outlook & Opportunities in Fiberglass Grating

The future of fiberglass grating is bright, propelled by several key upcoming trends and shifting buyer demands. As industries worldwide seek more efficient, durable, and environmentally conscious solutions, FRP materials are positioned for sustained growth. One significant trend is the increasing emphasis on longevity and reduced maintenance costs. Traditional materials often succumb to corrosion, chemical degradation, and fatigue, leading to costly repairs and replacements. Fiberglass grating, with its inherent resistance to these factors, offers a compelling alternative, extending service life and minimizing operational disruptions.

Buyer demand is also evolving towards more specialized and high-performance products. There's a growing need for application-specific grating solutions, such as anti-static frp platform grating for hazardous environments, fire-retardant frp micro mesh grating for public access areas, and UV-resistant frp protruded grating for outdoor installations. Manufacturers who can deliver customized solutions that meet niche requirements will capture a larger share of the market.

Significant opportunities are emerging at the intersection of composites technology and modern manufacturing paradigms:

- Automation in Manufacturing: Advanced robotics and automated pultrusion lines are enhancing production efficiency, consistency, and scalability for fiberglass grating. This reduces labor costs and increases output, making high-quality FRP solutions more accessible.

- Smart Manufacturing (Industry 4.0): Integrating IoT sensors and data analytics into the manufacturing process allows for real-time monitoring of quality, predictive maintenance of machinery, and optimization of material usage. This leads to superior product quality and more agile production.

- Sustainability Focus: The demand for eco-friendly materials and manufacturing processes is on the rise. Opportunities exist in developing FRP gratings using recycled content, bio-based resins, and in establishing closed-loop recycling programs for end-of-life composite products. Chinese manufacturers are increasingly investing in these green technologies, positioning themselves as leaders in sustainable composite solutions.

These trends indicate a clear path forward for buyers and businesses: prioritizing manufacturers who demonstrate innovation in product design, efficiency in production, and a commitment to environmental stewardship.

Buyer/Business Takeaways: Investing in Fiberglass Grating

For B2B decision-makers, understanding the strategic advantages of investing in fiberglass grating is crucial for long-term project success and operational efficiency. The benefits extend far beyond initial cost, impacting safety, maintenance, and overall return on investment (ROI).

- Superior Corrosion Resistance: Unlike metallic gratings, FRP is impervious to rust, chemical attack, and saltwater, making it ideal for harsh industrial, marine, and wastewater treatment environments. This significantly reduces replacement costs and extends service life.

- Exceptional Strength-to-Weight Ratio: FRP platform grating provides the structural integrity needed for heavy loads while being considerably lighter than steel. This eases installation, reduces transportation costs, and places less strain on supporting structures.

- Enhanced Safety Features: Non-conductive properties, flame retardancy, and anti-slip surfaces (especially with frp micro mesh grating and frp protruded grating) contribute to a safer working environment, reducing the risk of accidents and associated liabilities.

- Low Maintenance: FRP requires minimal upkeep, eliminating the need for painting, scraping, or cathodic protection, leading to significant savings over the product's lifespan.

- Design Versatility: FRP can be custom-fabricated to meet specific size, shape, and color requirements, offering design flexibility not possible with traditional materials.

Tips for Adopting or Partnering with Chinese Manufacturers:

- Conduct Thorough Due Diligence: Research potential partners' certifications (ISO, ASTM), track record, and client testimonials. Visit their facilities if possible or arrange virtual tours.

- Prioritize Quality Control: Ensure the manufacturer has robust QC processes in place, from raw material inspection to final product testing. Request samples and test reports. Zhaojia Composites, for instance, emphasizes strict quality control protocols that align with international standards.

- Communicate Clearly: Define specifications, tolerances, and delivery schedules explicitly. Cultural nuances in business communication should also be considered to avoid misunderstandings.

- Seek Customization Expertise: Many Chinese manufacturers, like Zhaojia Composites, excel in custom fabrication. Leverage this capability to obtain solutions perfectly tailored to your project's unique needs.

- Understand Logistics and Supply Chain: Factor in shipping times, customs procedures, and potential duties. Establish clear terms for freight and insurance.

Future-Proof Strategies:

To future-proof your strategies in the fiberglass grating market, consider integrating smart technologies into your infrastructure projects. Explore suppliers offering FRP solutions with embedded sensors for structural health monitoring or those that are compatible with IoT systems. Additionally, align with manufacturers who are investing in sustainable production methods and developing next-generation, environmentally friendly composite materials. By focusing on long-term value, advanced capabilities, and responsible sourcing, businesses can build resilient, efficient, and sustainable operations for the decades to come.

Conclusion: Shaping the Future of Composites

The China Composites Expo undeniably plays a pivotal role in shaping the global fiberglass grating market. It serves as a dynamic showcase for the latest innovations, advanced manufacturing techniques, and the strategic vision of leading manufacturers, particularly those from China who are rapidly advancing the industry's capabilities. The Expo highlights the growing importance of durable, lightweight, and corrosion-resistant FRP materials in addressing the complex challenges of modern infrastructure, renewable energy, and industrial applications.

Companies like Zhaojia Composites Co., Ltd, with their extensive portfolio of frp micro mesh grating, frp platform grating, and frp protruded grating, exemplify the commitment to quality, customization, and innovation that defines the leading edge of this industry. Their contributions, alongside those of other global leaders, are instrumental in driving forward the adoption of high-performance composite solutions worldwide.

As B2B decision-makers navigate the complexities of material selection and supplier partnerships, the insights gained from events like the China Composites Expo are invaluable. It underscores that strategic investment in advanced fiberglass grating is not just about purchasing a product; it's about securing long-term operational excellence, enhanced safety, and sustainable growth for your projects and business.

Ready to explore high-quality FRP solutions for your next project?

Visit Zhaojia Composites Co., Ltd to learn more about our holiday special offers on GRP/FRP Gratings.

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025