loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

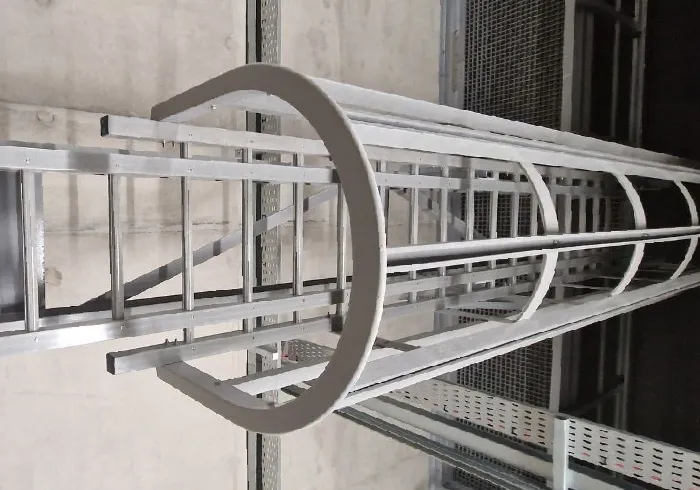

prefabricated handrail

The Advantages and Applications of Prefabricated Handrails

In today’s fast-paced construction environment, efficiency and safety are paramount. One innovative solution that addresses these needs is prefabricated handrails. These modular systems are designed off-site and brought to the construction location ready for installation. They offer numerous advantages for both residential and commercial projects.

Cost-Effectiveness

One of the most significant benefits of prefabricated handrails is their cost-effectiveness. Traditional handrail systems often require extensive labor hours to fabricate and install on-site. However, prefabricated options reduce the labor required since these systems are pre-assembled in a controlled environment. By decreasing on-site construction time, contractors can allocate resources more effectively, resulting in overall project savings.

Enhanced Safety

Safety is a crucial consideration in any construction project, particularly when it comes to stairways, balconies, and other elevated platforms. Prefabricated handrails are designed with safety compliance in mind. They adhere to strict building codes and regulations, ensuring that they can withstand impact and provide reliable support. Moreover, since these handrails are constructed off-site, there is a reduced risk of accidents associated with on-site fabrication and assembly, contributing to a safer work environment.

Customization Options

Prefabricated handrails come in a variety of styles, materials, and finishes, making it easier to achieve a desired aesthetic without compromising on safety. Whether looking for sleek modern designs or traditional style railing, manufacturers offer a plethora of customizable options. This adaptability allows architects and designers to incorporate handrails that complement the overall design of the building, enhancing both form and function.

prefabricated handrail

Quick Installation

Another compelling advantage of prefabricated handrails is the speed of installation. Because these systems arrive on-site pre-assembled, they can be installed quickly and efficiently. This quick turnaround is particularly beneficial for projects with tight deadlines. The less time spent on installing handrails means that other elements of the project can commence sooner, improving overall project timelines.

Durability and Maintenance

Durability is a crucial factor in the choice of handrail systems, particularly in outdoor or high-traffic environments. Prefabricated handrails can be made from corrosion-resistant materials such as aluminum, stainless steel, or high-quality PVC. These materials not only ensure a long lifespan but also minimize maintenance needs. This characteristic is especially advantageous for commercial properties where the upkeep can be labor-intensive and costly.

Environmentally Friendly Solutions

As sustainability becomes increasingly important in construction, prefabricated handrails can also contribute to greener building practices. They are often manufactured in ways that reduce waste, and many companies use recycled materials to create their products. Additionally, the reduced construction time on-site means less heavy machinery is required, further lowering the carbon footprint of the construction process.

Conclusion

In summary, prefabricated handrails offer a multitude of advantages for modern construction projects. From cost savings and enhanced safety to quick installation and customization options, they present a practical solution for builders and designers alike. As the demand for efficient construction practices increases, the popularity of prefabricated handrails is likely to grow, solidifying their place as a staple in both commercial and residential building projects. Embracing this innovative approach not only enhances the aesthetic appeal of structures but also ensures that they are built to last.

-

Premium FRP Handrail for All ApplicationsNewsAug.29,2025

-

Low Maintenance FRP Mini Mesh Grating ProductsNewsAug.29,2025

-

Innovative FRP Square Tubes for Modern Industrial SolutionsNewsAug.29,2025

-

FRP Water Storage Tanks Wholesale Solutions for Bulk BuyersNewsAug.29,2025

-

FRP Molded Grating Solutions for Diverse Industrial ApplicationsNewsAug.29,2025

-

Construction Advancements Through FRP Pultruded ProfilesNewsAug.29,2025

-

Why Choose FRP Railings, Guardrails, and Handrail Systems?NewsAug.29,2025