loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

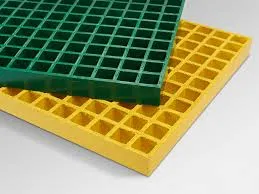

Benefits and Applications of Plastic Bar Grating in Modern Construction Projects

Understanding Plastic Bar Grating A Versatile Solution for Various Applications

Plastic bar grating is a versatile and innovative material that has gained popularity across multiple industries. It is a lightweight, corrosion-resistant alternative to traditional metal grating, offering numerous advantages that make it an attractive choice for a variety of applications. This article delves into the composition, benefits, uses, and maintenance of plastic bar grating, emphasizing why it has become a preferred option for many.

Composition and Design

Plastic bar grating is typically made from durable thermoplastic materials, such as fiberglass-reinforced plastic (FRP) or polyvinyl chloride (PVC). The manufacturing process involves the extrusion or molding of plastic into a grid-like structure, creating a series of parallel bars with spaces in between. This design allows for efficient drainage and ventilation while providing a stable platform for foot traffic or machinery.

The customizable designs available in plastic bar grating cater to various load requirements, making it suitable for both light and heavy-duty applications. The choice of colors and sizes also enables designers and engineers to align the grating with specific project needs and aesthetic preferences.

Advantages of Plastic Bar Grating

One of the primary advantages of plastic bar grating is its resistance to corrosion. Unlike metal grates, which can succumb to rust and degradation over time, plastic grating will not corrode when exposed to moisture, chemicals, or other harsh environmental conditions. This property is particularly beneficial in industries such as wastewater treatment, food processing, and chemical manufacturing, where exposure to corrosive substances is common.

Moreover, plastic bar grating is a lightweight alternative to metal options, which simplifies handling and installation. This feature reduces labor costs and minimizes the structural support needed for installation, making it an economical choice for projects requiring extensive grating coverage.

Safety is another vital consideration in many applications. Plastic bar grating can be designed with slip-resistant surfaces, enhancing safety in environments prone to spills or where wet conditions are expected. Additionally, its non-conductive properties make it an excellent choice for electrical installations, further reducing potential hazards.

Applications of Plastic Bar Grating

plastic bar grating

The versatility of plastic bar grating means it can be employed in various settings. Common applications include

1. Industrial Facilities In factories and manufacturing plants, plastic bar grating can be used for walkways, platforms, and drainage systems due to its slip resistance and ability to withstand heavy loads.

2. Municipal Projects Plastic grating is often found in public spaces such as parks and playgrounds. Its durability and resistance to the elements ensure longevity in outdoor applications.

3. Water Treatment Plants The non-corrosive properties of plastic grating make it an ideal choice in environments where exposure to water and chemicals is constant. It can be used in walkways, stair treads, and as covers for drainage areas.

4. Agricultural Settings In livestock operations, plastic bar grating can provide safe flooring solutions that are easy to clean and maintain, contributing to overall hygiene and efficiency.

5. Marine Applications The lightweight and corrosion-resistant nature of plastic bar grating makes it suitable for docks, piers, and other coastal structures.

Maintenance Requirements

One of the appealing features of plastic bar grating is its low maintenance requirements. Regular cleaning with water and mild detergents is sufficient to keep it in good condition. Unlike metal grates, there is no need for painting or rust prevention treatments, which saves time and resources.

In conclusion, plastic bar grating is a compelling choice for various applications due to its durability, safety features, and environmental resistance. Its lightweight nature simplifies installation, while its versatility allows for use across multiple industries. As sustainability becomes more paramount in construction and engineering, the demand for innovative materials like plastic bar grating is likely to increase, paving the way for its continued adoption. Whether for industrial, municipal, or agricultural applications, plastic bar grating provides a reliable solution that meets the diverse needs of modern infrastructure.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025