loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

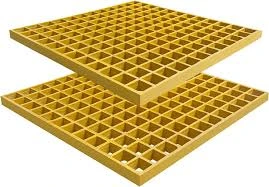

moulded fibreglass grating

The Advantages and Applications of Moulded Fibreglass Grating

Moulded fibreglass grating, commonly known as FRP (Fibreglass Reinforced Plastic) grating, has emerged as a highly effective and versatile solution for various industrial and commercial applications. This innovative material is renowned for its unique properties, including high strength-to-weight ratio, corrosion resistance, and low maintenance requirements. As industries around the world seek materials that not only meet safety and performance standards but also contribute to long-term sustainability, moulded fibreglass grating stands out as an excellent choice.

Strength and Durability

One of the most significant advantages of moulded fibreglass grating is its exceptional strength and durability. Manufactured through a process that combines fibreglass strands and resin, this grating exhibits a remarkable strength-to-weight ratio. It is capable of supporting heavy loads while remaining lightweight and easy to install. Unlike traditional materials such as steel or wood, which can corrode, rot, or degrade over time, FRP grating maintains its structural integrity even in harsh environments. This resilience makes it an ideal choice for applications in industries such as chemical processing, oil and gas, and wastewater treatment, where exposure to extreme conditions is common.

Corrosion Resistance

Corrosion is a significant concern in many industrial settings, especially those that handle aggressive chemicals or are located in coastal areas. Moulded fibreglass grating is inherently resistant to corrosion, owing to its non-metallic composition. This characteristic not only extends the lifespan of the material but also reduces the need for frequent replacements, translating to cost savings over time. Facilities that opt for FRP grating can minimize downtime and maintenance costs, allowing for more efficient operations.

Safety Features

Safety is a critical factor in industrial workplaces, and moulded fibreglass grating can significantly enhance safety measures. The surfaces of FRP grating can be engineered to provide slip resistance, which is especially important in environments that may become wet or greasy. This feature reduces the likelihood of workplace accidents and injuries, protecting employees and minimizing liability issues for employers. Additionally, fibreglass grating is non-conductive, providing an extra layer of safety in electrical environments.

moulded fibreglass grating

Lightweight and Easy Installation

The lightweight nature of moulded fibreglass grating simplifies the installation process. Unlike heavy metal grates that require complex lifting equipment and extensive manpower, FRP grating can be easily handled and installed by a smaller crew. This not only speeds up the construction process but also reduces labor costs. Furthermore, moulded fibreglass grating can be fabricated to meet specific project requirements, including customized sizes and designs, enhancing its versatility in various applications.

Eco-Friendly Option

In an era where sustainability is a focal point for many industries, moulded fibreglass grating offers an environmentally friendly alternative to conventional materials. Fibreglass grating is manufactured from recyclable materials, contributing to a reduced environmental footprint. Additionally, its durability and low maintenance requirements mean fewer resources are consumed over the grating's lifecycle, aligning with corporate sustainability goals.

Applications Across Industries

The versatility of moulded fibreglass grating makes it suitable for a wide range of applications. It is widely used in walkways, platforms, stair treads, and trench covers across industries such as pharmaceuticals, food and beverage, marine, and mining. Its ability to resist chemicals, UV radiation, and extreme temperatures ensures that it performs well in diverse settings.

Conclusion

Moulded fibreglass grating is a powerful solution for modern industrial challenges. With its strength, durability, corrosion resistance, and safety features, it is quickly becoming the go-to choice for engineers and facility managers looking to optimize performance while maintaining safety and sustainability. As industries continue to evolve, the demand for innovative materials like moulded fibreglass grating will undoubtedly rise, paving the way for safer and more efficient workplaces.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025