loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Feb . 10, 2025 10:11

Back to list

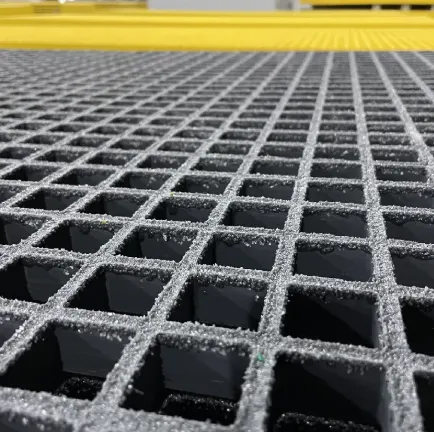

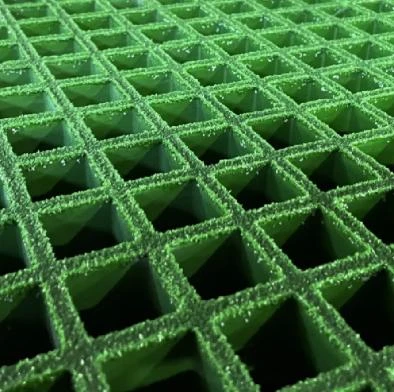

frp micro mesh grating

Molded grating has revolutionized industrial flooring, offering an exceptional blend of durability, versatility, and safety features. As industrial environments continually demand materials that withstand rigorous conditions while maintaining functional integrity, molded grating has emerged as a leading choice. This material is engineered to provide maximum performance across a variety of applications, establishing itself as a vital component in sectors ranging from manufacturing to marine facilities.

Customizability is another prominent feature of molded grating. Available in an array of colors, sizes, and configurations, it provides the flexibility needed to meet specific aesthetic and functional demands. This adaptability ensures that molded grating can integrate seamlessly into existing structures or form the basis of new design concepts, offering architects and engineers ample scope for creativity without sacrificing practicality. Transitioning to molded grating can also contribute towards sustainability goals. Its extended lifecycle reduces the frequency of replacements, thus minimizing waste. Furthermore, many molded grating products are manufactured with an eye on environmental responsibility, using resins that meet stringent environmental standards. The adoption of molded grating marks a significant shift towards improved operational excellence across various industries. Its reputation is backed by extensive research and field evaluations by experts who consistently highlight its long-term value and performance. As more industries recognize the advantages of molded grating, it becomes clear that this innovative product is not just an option, but an essential investment in the pursuit of safety, efficiency, and sustainability. In conclusion, molded grating stands out as a product of choice for industries aiming to combine durability, safety, and efficiency. Its development and application encapsulate a blend of innovation and proven performance, offering a solution that meets contemporary industrial demands. Those considering molded grating can trust in its capacity to deliver exemplary results, substantiated by its track record and the authoritative endorsements from industry experts.

Customizability is another prominent feature of molded grating. Available in an array of colors, sizes, and configurations, it provides the flexibility needed to meet specific aesthetic and functional demands. This adaptability ensures that molded grating can integrate seamlessly into existing structures or form the basis of new design concepts, offering architects and engineers ample scope for creativity without sacrificing practicality. Transitioning to molded grating can also contribute towards sustainability goals. Its extended lifecycle reduces the frequency of replacements, thus minimizing waste. Furthermore, many molded grating products are manufactured with an eye on environmental responsibility, using resins that meet stringent environmental standards. The adoption of molded grating marks a significant shift towards improved operational excellence across various industries. Its reputation is backed by extensive research and field evaluations by experts who consistently highlight its long-term value and performance. As more industries recognize the advantages of molded grating, it becomes clear that this innovative product is not just an option, but an essential investment in the pursuit of safety, efficiency, and sustainability. In conclusion, molded grating stands out as a product of choice for industries aiming to combine durability, safety, and efficiency. Its development and application encapsulate a blend of innovation and proven performance, offering a solution that meets contemporary industrial demands. Those considering molded grating can trust in its capacity to deliver exemplary results, substantiated by its track record and the authoritative endorsements from industry experts.

Share

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025