loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

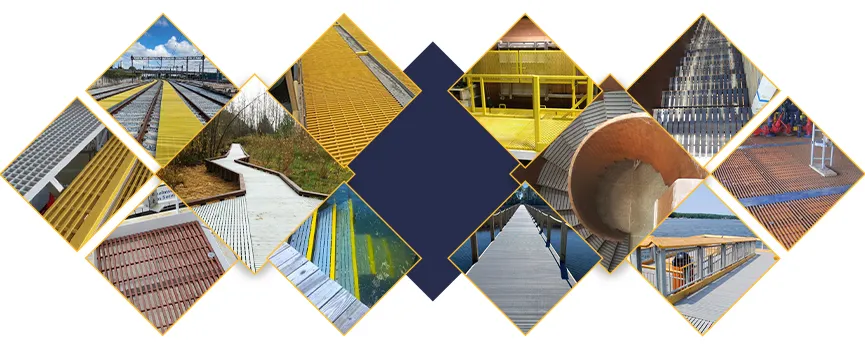

Innovative Designs in Molded Gratings for Enhanced Performance and Durability

Understanding Molded Grating A Comprehensive Overview

Molded grating is a versatile and innovative material that has gained popularity in various industrial applications. It is primarily made from fiberglass reinforced plastic (FRP) or other composite materials, making it a lightweight yet strong alternative to traditional metal grating. The unique manufacturing process of molded grating allows for the integration of unique properties, making it suitable for a wide range of environments.

Manufacturing Process

The production of molded grating involves the use of a fiberglass matrix that is reinforced with a suitable resin. This combination leads to a durable and corrosion-resistant material that can withstand harsh environmental conditions. The process typically starts with the creation of a mold, where the fiberglass and resin are laid in layers. Once the materials are cured, the mold is removed, revealing the final product. This method not only reduces weight but also allows for custom products tailored to specific requirements.

Key Features

Molded grating possesses several features that make it a preferred choice in various applications

1. Corrosion Resistance One of the standout characteristics of molded grating is its resistance to corrosive substances. Unlike traditional metal grating, which can rust and weaken over time, molded grating maintains its integrity even in the presence of chemicals, moisture, and UV rays.

2. Lightweight The use of composite materials makes molded grating significantly lighter than metal alternatives. This lightweight nature reduces installation costs and labor required for transport and handling.

3. Slip Resistance Molded grating can be designed with a surface texture that enhances slip resistance, making it ideal for walkways and platforms where safety is a concern. This feature is vital in industries such as food processing, pharmaceuticals, and oil & gas.

molded grating

4. Easy Maintenance The smooth surface of molded grating allows for easy cleaning and maintenance, a crucial attribute in environments that require high hygiene standards.

5. Customization Molded grating can be fabricated in various sizes, colors, and load capacities, enabling it to be tailored to specific needs. This flexibility makes it suitable for diverse applications, from industrial flooring to architectural designs.

Applications

Molded grating is utilized across numerous industries, showcasing its versatility. In the chemical processing industry, for example, it is often employed in platforms and walkways where exposure to corrosive agents is prevalent. In water treatment facilities, molded grating can be found in trenches and covers, providing both functionality and safety. Additionally, molded grating is used in food and beverage industries, where cleanliness is paramount.

Moreover, the construction and architectural sectors utilize molded grating to create visually appealing and durable surfaces. Its ability to withstand extreme conditions while providing aesthetic value is a significant advantage.

Environmental Benefits

As sustainability becomes increasingly important, molded grating stands out as an eco-friendly alternative. Its longevity and resistance to wear result in less frequent replacement compared to metal grates, which have a higher rate of corrosion. Furthermore, many manufacturers are adopting practices that enhance the recyclability of molded grating, contributing to a circular economy.

Conclusion

Molded grating is more than just a functional solution; it is a product that embodies innovation, safety, and sustainability. Its manufacturing process, combined with its outstanding features and wide range of applications, make it an attractive option for various industries. As companies continue to look for materials that enhance durability while being environmentally responsible, molded grating will undoubtedly play a pivotal role in shaping the future of industrial and architectural designs. With its proven benefits and adaptability, molded grating is set to remain a preferred choice for years to come.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025