loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Advancements in Molded Fiber Reinforced Polymer Technology for Enhanced Performance Applications

The Rise of Molded FRP Revolutionizing Composite Materials

In recent years, the field of materials science has witnessed a significant transformation with the introduction of molded fiber-reinforced plastics (FRP). This innovative material has gained traction across various industries due to its remarkable properties, including high strength-to-weight ratio, corrosion resistance, and versatility in application. As we delve deeper into the benefits and applications of molded FRP, it becomes clear why this material is considered a game-changer in modern engineering.

Understanding Molded FRP

Molded FRP is primarily manufactured by combining a polymer matrix, typically polyester or epoxy, with reinforcement fibers such as glass, carbon, or aramid. The unique aspect of molded FRP lies in the manufacturing process, where the material is shaped in a mold to create specific forms, allowing for complex designs that meet various engineering requirements. This process not only enhances the material's structural integrity but also contributes to its aesthetic appeal, making it suitable for both functional and decorative applications.

Benefits of Molded FRP

One of the foremost advantages of molded FRP is its exceptional strength-to-weight ratio. Compared to traditional materials like steel or aluminum, molded FRP offers similar or even superior strength while being significantly lighter. This attribute is particularly beneficial in industries such as aerospace and automotive, where reducing weight can lead to enhanced fuel efficiency and lower emissions.

Moreover, molded FRP exhibits extraordinary resistance to corrosion and environmental degradation. Unlike metals that can rust or corrode when exposed to moisture, FRP materials maintain their integrity even in harsh environmental conditions. This makes them ideal for use in marine applications, chemical processing plants, and infrastructure projects where exposure to corrosive substances is a concern.

Another significant feature of molded FRP is its thermal and electrical insulation properties. The material does not conduct electricity, making it a safe choice for electrical applications. Additionally, its low thermal conductivity helps maintain temperature stability in various settings, which is crucial for thermal management systems in industrial environments.

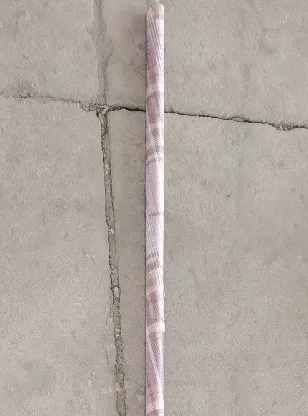

molded frp

Diverse Applications

The applications of molded FRP are vast and varied, spanning multiple sectors. In the construction industry, FRP is increasingly used for reinforcement purposes in concrete structures, where it enhances strength and durability without adding substantial weight. Its aesthetic potential has also made it a popular choice in architectural design, providing innovative solutions for facades and interior finishes.

In the automotive sector, many manufacturers are exploring molded FRP components to improve the performance and efficiency of vehicles. Components such as body panels, dashboards, and structural reinforcements benefit from the lightweight yet strong characteristics of FRP, enabling manufacturers to produce vehicles that are not only robust but also more fuel-efficient.

The aerospace industry has also embraced molded FRP for similar reasons. Aircraft components such as wings, fuselage sections, and interior fittings are increasingly being produced from FRP to reduce weight and improve overall performance. As technology advances, the incorporation of FRP in commercial and military aircraft is expected to continue growing.

Challenges and Future Prospects

Despite its many advantages, molded FRP is not without challenges. The production process can be energy-intensive, and the recycling of FRP materials remains a concern, as traditional recycling methods are often ineffective for composites. However, ongoing research and development aim to address these issues, with advancements in eco-friendly production techniques and improved recycling methods on the horizon.

As industries continue to explore and harness the potential of molded FRP, it is clear that this innovative material offers numerous benefits that can meet the demands of modern engineering challenges. With its strength, lightweight characteristics, and resistance to environmental factors, molded FRP is poised to play a crucial role in shaping the future of various sectors, ultimately leading to more sustainable and efficient solutions.

In conclusion, molded FRP stands out as a revolutionary material with the potential to transform industries ranging from construction to aerospace. By leveraging its unique properties and addressing the existing challenges, we can unlock new opportunities and pave the way for advancements that capitalize on the strength and versatility of this remarkable composite material.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025