loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Innovative Applications of Molded FRP in Modern Construction and Design

The Advantages of Molded Fiber Reinforced Polymer (FRP) in Modern Applications

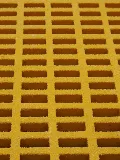

Molded Fiber Reinforced Polymer (FRP) stands at the forefront of materials science, combining the best qualities of polymers and the strength of fiber reinforcements such as glass, carbon, or aramid. This innovative composite material has seen a surge in popularity across various industries due to its unique properties and versatility.

The Advantages of Molded Fiber Reinforced Polymer (FRP) in Modern Applications

Durability is another noteworthy feature of molded FRP. This material exhibits excellent resistance to environmental factors, including moisture, chemicals, and UV radiation. As a result, molded FRP components can withstand harsh conditions without succumbing to corrosion or degradation, making them ideal for use in marine applications, chemical processing, and outdoor furnishings. For example, FRP is increasingly used in the manufacturing of boats, as it provides a strong yet lightweight option that resists the corrosive effects of seawater.

molded frp

Moreover, molded FRP offers design flexibility that is unmatched by traditional materials. The molding process allows for intricate designs and complex shapes to be produced with precision. Manufacturers can easily tailor the thickness, color, and finish of FRP components to meet specific project requirements, enhancing both aesthetic appeal and functionality. This adaptability makes FRP an exciting choice for architectural applications, where creative and durable solutions are essential.

Cost-effectiveness is a crucial factor driving the adoption of molded FRP. Although the initial investment in FRP technology may be higher than that of conventional materials, the long-term savings are substantial. The low maintenance requirements and longevity of FRP products lead to lower lifecycle costs. Companies benefit from reduced downtime and fewer replacements, contributing to overall efficiency and profitability.

Furthermore, FRP is a sustainable option in an era where environmental considerations are paramount. The production and use of molded FRP can be more eco-friendly compared to traditional materials, as it often incorporates recycled fibers and can be designed for recyclability at the end of its life cycle.

In conclusion, molded Fiber Reinforced Polymer is revolutionizing various sectors with its lightweight, durable, and versatile nature. As technology advances, we can expect even broader applications and innovations, making molded FRP a cornerstone of modern engineering and design. Its benefits not only enhance functionality and performance but also address the growing demand for sustainable materials in today's world.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025