loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

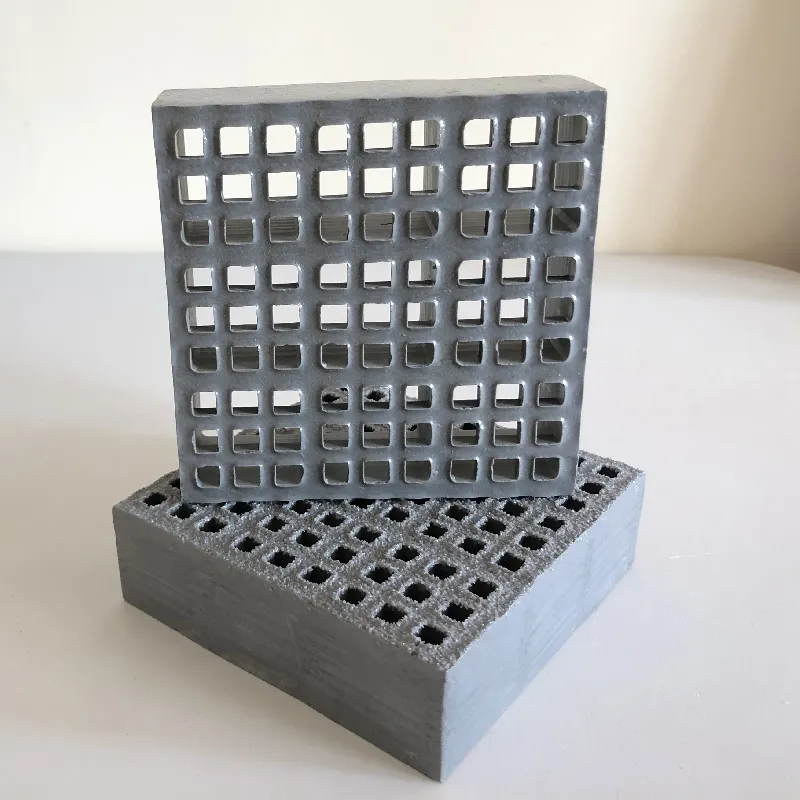

molded fiberglass grating

The Benefits and Applications of Molded Fiberglass Grating

Molded fiberglass grating, also known as fiberglass reinforced plastic (FRP) grating, has emerged as a revolutionary product in various industries due to its superior properties and versatile applications. This material is manufactured by combining fiberglass and resin under heat and pressure, resulting in a durable, corrosion-resistant structure that is ideal for a variety of demanding environments. In this article, we will explore the benefits of molded fiberglass grating, as well as its common applications across different sectors.

Durability and Corrosion Resistance

One of the standout features of molded fiberglass grating is its exceptional durability. Unlike traditional materials such as steel or wood, fiberglass does not rust or corrode when exposed to harsh chemicals or environmental conditions. This makes it an excellent choice for industries such as chemical processing, wastewater treatment, and marine applications, where exposure to corrosive substances is a daily challenge. The longevity of molded fiberglass grating not only ensures a longer lifespan but also reduces the need for frequent replacements, leading to cost savings for businesses.

Lightweight and Easy to Install

Molded fiberglass grating is significantly lighter than its metal counterparts, which simplifies transportation and installation. This lightweight nature allows for easier handling, reducing labor costs and the need for heavy lifting equipment during installation. Additionally, the ease of cutting and modifying fiberglass grating on-site means that it can be adapted to fit specific designs and requirements without the need for expensive specialized tools.

Safety and Slip Resistance

Safety is paramount in industrial settings, and molded fiberglass grating excels in this area. The surface of molded grating is designed to provide superior slip resistance, minimizing the likelihood of accidents in wet or oily conditions. Furthermore, it is designed to be both lightweight and sturdy, providing a secure footing for workers. The open design of the grating also allows for drainage, preventing the accumulation of liquids that can lead to hazardous situations.

molded fiberglass grating

Versatile Applications

Molded fiberglass grating is versatile and applicable in many sectors. In the chemical and petrochemical industries, it is widely used for platforms, walkways, and stair treads where exposure to chemicals is common. In the wastewater treatment sector, it is used for walkways, trench covers, and platforming that need to withstand harsh waste chemicals. For marine applications, molded fiberglass grating provides a non-corrosive and slip-resistant solution for docks and offshore platforms.

Moreover, molded fiberglass grating is utilized in the food and beverage industry, where hygiene is crucial. Its resistance to corrosion means that it can withstand regular cleaning with harsh chemicals without degrading. As such, it is often used in processing areas, storage facilities, and distribution centers.

Environmental Considerations

In today's eco-conscious world, the environmental impact of products is more significant than ever. Molded fiberglass grating is a more sustainable choice compared to many traditional materials. With a longer life span, less frequent replacements, and minimal maintenance requirements, fiberglass grating contributes to reduced waste. Additionally, many manufacturers are leaning towards sustainable practices by producing fiberglass grating with recycled materials, further increasing its environmental appeal.

Conclusion

The benefits of molded fiberglass grating are numerous and diverse, making it a compelling material for various applications across multiple industries. From its remarkable durability and resistance to corrosion to its safety features and versatility, molded fiberglass grating presents a well-rounded solution for both industrial and commercial needs. As industries continue to evolve, the demand for efficient, durable, and environmentally friendly materials like molded fiberglass grating will likely grow. Investing in such materials not only enhances operational efficiency but also aligns with sustainable practices, ensuring a safer and more responsible approach to industrial construction and maintenance. With the ever-increasing focus on safety, durability, and environmental impact, molded fiberglass grating is poised to play an integral role in the future of industrial material technology.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025