loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

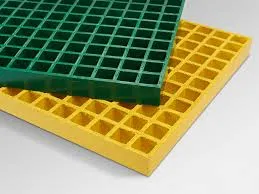

molded frp

The Rise of Molded FRP A Look into Its Applications and Benefits

Molded Fiberglass Reinforced Plastic (FRP) has emerged as a prominent material across various industries due to its unique combination of strength, durability, and versatility. This composite material, made from a polymer matrix reinforced with fiberglass, has revolutionized the manufacturing processes in sectors such as construction, automotive, aerospace, and marine.

The Rise of Molded FRP A Look into Its Applications and Benefits

In addition to its lightweight properties, molded FRP is highly resistant to corrosion, making it an ideal choice for applications in harsh environments. Industries such as chemical processing and wastewater treatment often utilize FRP tanks, piping, and various components because they can withstand exposure to aggressive chemicals and humidity without succumbing to rust or degradation. This durability extends the lifespan of these products, reducing maintenance costs and increasing reliability.

molded frp

The versatility of molded FRP is another appeal. It can be easily molded into complex shapes and sizes, allowing for innovative designs that would be difficult or impossible to achieve with traditional materials. This adaptability means that molded FRP can be customized for specific applications, whether it's for creating intricate architectural elements or designing functional components for machinery. Moreover, the material can be manufactured in various colors and finishes, enhancing aesthetic value.

Additionally, molded FRP is an environmentally friendly option compared to many traditional materials. Its production typically generates less waste, and when properly processed, the material can be recycled at the end of its life cycle. This sustainability aspect aligns with the growing demand for eco-friendly solutions across industries, as companies seek to reduce their carbon footprints and commit to greener practices.

In conclusion, molded FRP is a cutting-edge material that has significantly impacted numerous industries. Its lightweight nature, corrosion resistance, versatility, and environmental benefits make it an attractive option for manufacturers seeking to improve product performance while minimizing costs. As technology advances and manufacturing processes evolve, the use of molded FRP is expected to expand further, leading to innovative applications that will continue to transform various sectors.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025