loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

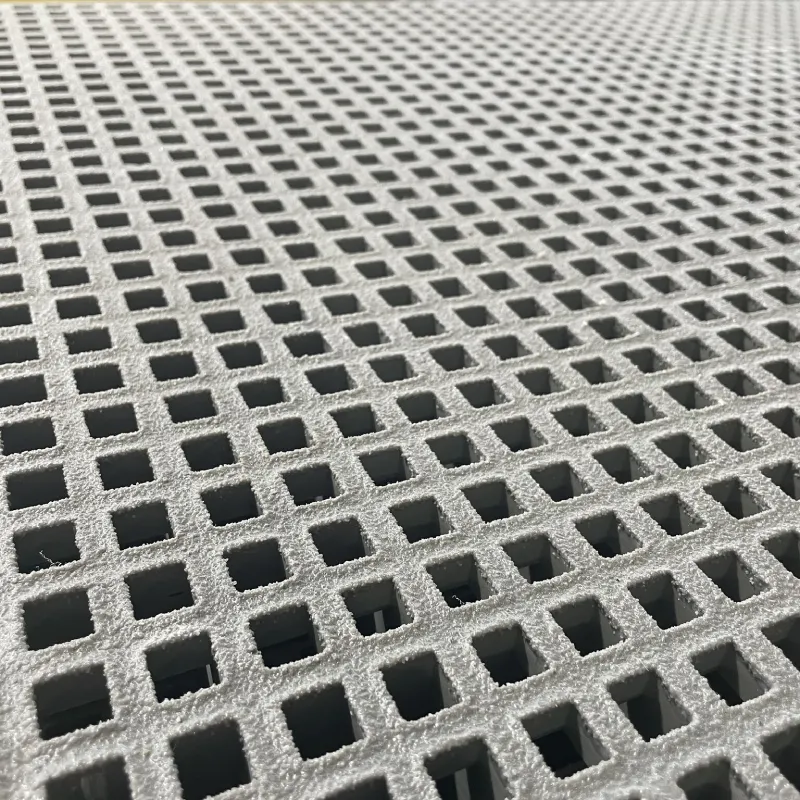

Mini Mesh Grating: Strong, Safe GRP/FRP Anti-Slip Solutions

Introduction to Advanced Composite Gratings and Industry Trends

In diverse industrial environments, the demand for high-performance, durable, and corrosion-resistant structural materials is continuously evolving. Traditional materials often fall short in challenging applications marked by chemical exposure, high moisture, or heavy operational loads. This has driven the widespread adoption of Fiber Reinforced Polymer (FRP) and Glass Reinforced Plastic (GRP) composite solutions. Among these, mini mesh grating stands out as a critical innovation, offering superior safety and operational efficiency.

Industry trends indicate a significant shift towards lightweight, low-maintenance materials that contribute to longer asset lifecycles and reduced operational expenditures. The global market for FRP composites, including gratings, is projected to grow substantially, fueled by infrastructure development, chemical processing, and renewable energy sectors. This growth is underpinned by the inherent advantages of composites over steel or aluminum, particularly in terms of corrosion resistance, dielectric properties, and an impressive strength-to-weight ratio. The specialized design of mini mesh grating, with its smaller open areas, addresses specific safety and functional requirements, making it an increasingly preferred choice for demanding applications.

This technical deep dive explores the manufacturing, specifications, advantages, and applications of this advanced material, providing B2B decision-makers and engineers with comprehensive insights to inform their material selection processes.

Manufacturing Process Flow of FRP Mini Mesh Grating

The production of high-quality mini mesh grating is a meticulous process, predominantly utilizing the molding technique for FRP/GRP composites. This method ensures consistent structural integrity, precise dimensions, and optimal mechanical properties.

Key Materials:

- Resins: The choice of resin dictates chemical resistance and fire retardancy. Common types include:

- Orthophthalic Polyester Resin: General-purpose, cost-effective, good corrosion resistance to mild acids and alkalis.

- Isophthalic Polyester Resin: Enhanced chemical resistance, particularly to strong acids, and better temperature performance.

- Vinyl Ester Resin: Superior corrosion resistance to a broad range of aggressive chemicals, high temperature tolerance, and excellent impact strength.

- Phenolic Resin: Exceptional fire resistance, low smoke emission, and high-temperature stability, ideal for offshore and tunneling applications.

- Fiberglass Rovings: Continuous glass fiber strands provide the primary structural reinforcement, contributing to the grating's strength and stiffness. E-glass is commonly used for its balance of properties.

- Fillers & Additives: Include fire retardants (e.g., alumina trihydrate), UV inhibitors, pigments for coloration, and thixotropic agents to control viscosity.

Manufacturing Process Steps:

- Mold Preparation: High-precision molds, typically made from steel or aluminum, are coated with a release agent to ensure easy demolding and a smooth surface finish.

- Resin Mixture Preparation: The chosen resin is carefully mixed with catalysts, promoters, pigments, and other additives to achieve the desired properties and cure time.

- Fiberglass Lay-up: Layers of continuous fiberglass rovings are strategically placed into the mold, forming a grid pattern. This ensures multi-directional strength.

- Resin Saturation: The prepared resin mixture is poured into the mold, thoroughly impregnating the fiberglass rovings. This step is critical for eliminating air voids and ensuring complete encapsulation of the fibers.

- Curing: The filled mold is then subjected to a controlled curing process, often involving heat, to initiate the polymerization of the resin. This transforms the liquid resin into a solid, rigid composite structure.

- Demolding: Once fully cured, the grating panel is carefully removed from the mold.

- Post-Processing & Finishing: Excess material (flash) is trimmed, and the grating may undergo surface treatments such as applying a grit surface for enhanced slip resistance. Quality control checks for dimensional accuracy, visual defects, and mechanical properties are performed.

Testing Standards & Service Life:

Manufacturing adheres to rigorous international standards such as ASTM (e.g., ASTM E84 for flame spread and smoke development, ASTM D638 for tensile properties, ASTM D790 for flexural properties), ISO 9001 for quality management, and various EN standards (e.g., EN ISO 14122-3 for industrial platforms and walkways). These standards ensure product reliability and safety. The service life of FRP/GRP mini mesh grating, when correctly specified and installed, often exceeds 20 years, even in harsh corrosive environments, significantly outperforming traditional materials.

Target Industries & Advantages:

The primary industries benefiting from mini mesh grating include petrochemical, metallurgy, water supply & drainage, marine & offshore, chemical processing, food & beverage, and power generation. Its advantages in these scenarios are pronounced:

- Corrosion Resistance: Unaffected by most acids, alkalis, salts, and solvents, eliminating rust and significantly reducing maintenance costs.

- Energy Saving: In applications where under-grating lighting is used, the smaller open mesh area of mini mesh grating can sometimes enhance light distribution or reduce glare, contributing to a more controlled environment.

- Enhanced Safety: The tighter mesh openings prevent small tools, parts, or personal items from falling through, and its non-conductive properties provide electrical safety in hazardous zones.

Technical Specifications and Parameters of FRP Mini Mesh Grating

The technical specifications of mini mesh grating are crucial for engineers and procurement specialists to ensure optimal performance for specific application requirements. Its design features smaller load-bearing bar spacing and denser mesh, making it ideal for pedestrian traffic, areas requiring high foot comfort, or preventing small item drop-through.

Typical Product Specifications:

| Parameter | Specification/Value (Typical) |

|---|---|

| Product Name | Smaller Open Mesh Area FRP Mini Mesh Grating |

| Standard Panel Size | Approx. 1220x3660mm (4'x12'), 915x3050mm (3'x10') - Varies by manufacturer |

| Standard Mesh Size (Center-to-Center) | 19x19mm (3/4"x3/4"), 25x25mm (1"x1"), 30x30mm, 38x19mm, 38x38mm for smaller objects |

| Open Mesh Area | Approximately 30-45% (significantly less than standard gratings) |

| Standard Thickness/Height | 15mm (5/8"), 25mm (1"), 30mm (1.18"), 38mm (1.5") |

| Resin Types Available | Orthophthalic, Isophthalic, Vinyl Ester, Phenolic |

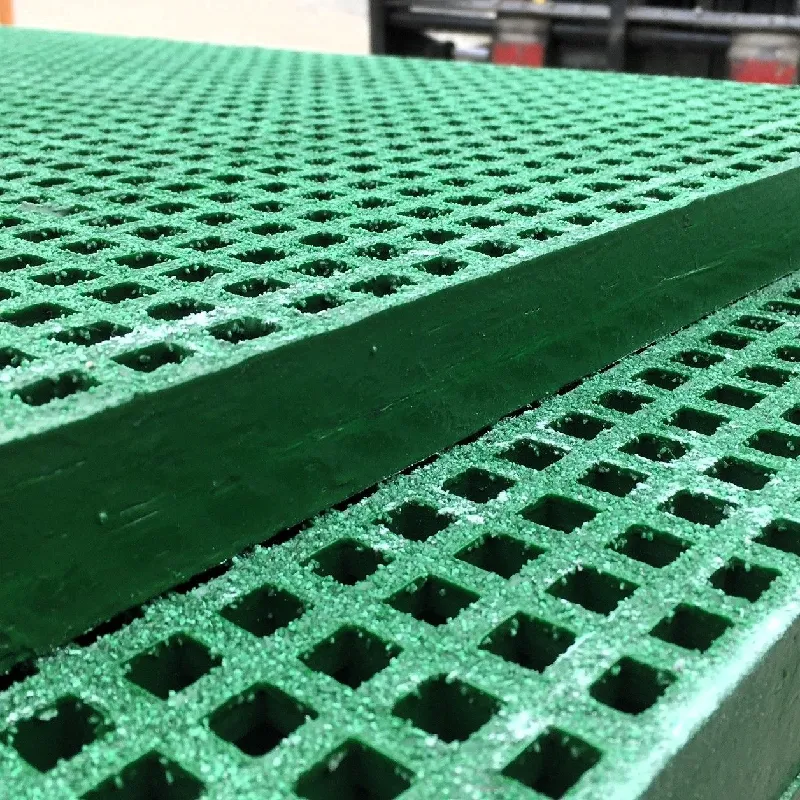

| Surface Finish | Concave (standard), Gritted (superior anti-slip), Plain |

| Fire Retardancy (ASTM E84) | Class 1 (Flame Spread Index < 25) with specific resin systems |

| Load Capacity | Varies significantly by thickness and span; consult load tables for specific requirements. Typically engineered for pedestrian and light vehicular traffic. |

| Colors | Yellow, Grey, Green, Red, Blue, Black (custom colors available) |

| Temperature Range | -50°C to +100°C (depending on resin type) |

Technical Terminology Explained:

- Open Mesh Area: The percentage of the grating's surface that is open space. A smaller open mesh area in mini mesh grating means more surface material, providing better support for smaller objects and enhanced foot comfort.

- Load-Bearing Bars: The primary structural elements that support weight. In mini mesh, these are more closely spaced, distributing loads over a larger number of bars.

- Deflection: The amount of displacement or bending that occurs under a given load. Minimized deflection is crucial for safety and structural integrity, especially for pedestrian comfort.

- Flame Spread Index (FSI): A numerical value obtained from the ASTM E84 test, indicating how quickly flames spread across a material's surface. Class 1 (FSI < 25) is the highest fire rating for building materials.

These parameters ensure that the grating meets specific environmental, safety, and load-bearing requirements, providing a robust and reliable solution for industrial platforms and walkways.

Key Technical Advantages of FRP Mini Mesh Grating

The advanced composite construction of mini mesh grating confers a distinct array of technical advantages over traditional materials such as metallic gratings. These benefits translate directly into enhanced safety, reduced operational costs, and extended operational lifespans for industrial infrastructure.

- Superior Corrosion Resistance: Unlike steel, FRP mini mesh grating is impervious to rust, galvanic corrosion, and degradation from a vast range of chemicals, including strong acids, alkalis, and salts. This makes it indispensable in aggressive chemical processing plants, wastewater treatment facilities, and marine environments where metallic gratings would rapidly deteriorate. This advantage significantly reduces maintenance and replacement costs over the product's lifespan.

- High Strength-to-Weight Ratio: While being considerably lighter than steel (typically 1/3 to 1/4 the weight), FRP mini mesh grating offers comparable or superior load-bearing capabilities. This facilitates easier and faster installation, reducing labor costs and equipment requirements. It also places less structural load on existing support structures, potentially allowing for lighter overall construction.

- Enhanced Safety Features:

- Anti-Slip Surface: Available with a highly effective grit surface, FRP mini mesh grating provides excellent slip resistance, even in wet, oily, or icy conditions, significantly reducing the risk of slips and falls.

- Non-Conductive: As a dielectric material, FRP grating is electrically non-conductive, making it safe for use in areas with electrical hazards, substations, and sensitive electronic equipment.

- Low Thermal Conductivity: It remains comfortable to touch even in extreme temperatures, preventing burns in hot environments and providing insulation in cold ones.

- Small Opening Size: The 'mini mesh' design with smaller apertures prevents tools, small components, and personal items (e.g., keys, jewelry) from falling through, safeguarding equipment and personnel. It also enhances pedestrian comfort by providing a more solid walking surface, particularly for those wearing high heels or with mobility aids.

- Long Service Life & Low Maintenance: Due to its inherent durability and resistance to degradation, FRP mini mesh grating requires minimal maintenance. It does not need painting, galvanizing, or rust removal, leading to substantial savings in upkeep expenses and maximizing operational uptime. Its expected service life often exceeds two decades.

- Impact Resistance: FRP composites possess excellent resilience and can absorb impact without permanent deformation, making them resistant to denting and bending, common issues with metallic gratings.

- Fire Retardant Properties: When manufactured with specific resin systems and additives, mini mesh grating can achieve excellent fire ratings (e.g., ASTM E84 Class 1), reducing flame spread and smoke emission, crucial for safety in enclosed or high-risk areas.

- UV Resistance: Incorporated UV inhibitors protect the grating from degradation and color fade when exposed to prolonged sunlight, ensuring long-term aesthetic and structural integrity in outdoor applications.

These combined attributes position FRP mini mesh grating as a superior material choice for critical infrastructure, delivering a compelling return on investment through enhanced safety, longevity, and reduced total cost of ownership.

Application Scenarios and Case Studies

The unique properties of mini mesh grating make it exceptionally versatile across a multitude of industrial and commercial applications where safety, durability, and corrosion resistance are paramount.

Typical Usage Scenarios:

- Walkways and Catwalks: Providing safe and stable access in corrosive environments, especially where tools or small items might be dropped. The smaller openings improve foot comfort, reducing fatigue for personnel.

- Trench and Pit Covers: Ideal for covering trenches in chemical plants, food processing facilities, or electrical substations, preventing equipment or personnel from falling in, while resisting chemical attack.

- Work Platforms and Access Ways: Used around machinery, tanks, and sumps, offering slip-resistant surfaces that withstand spills and heavy pedestrian traffic.

- Splash Zones and Washdown Areas: Excellent for marine environments, car washes, and food processing plants due to its non-corrosive nature and ease of cleaning.

- Food and Beverage Processing: Meets hygiene standards, is resistant to cleaning agents, and prevents small food particles from falling through, making it suitable for floors, platforms, and drainage covers.

- Electrical Substation and Cable Trench Covers: Its non-conductive properties ensure safety around live electrical components, preventing electrical hazards.

- Offshore Platforms: Lightweight, corrosion-resistant, and fire-retardant options are crucial for ensuring safety and longevity in harsh marine conditions.

Customer Feedback & Service Case Detail:

A major chemical manufacturing facility in the Gulf Coast region faced persistent issues with steel grating corrosion in their phosphoric acid processing area. The highly acidic environment led to frequent grating failures, requiring costly replacements every 18-24 months and significant downtime. The client also reported concerns about small tool drop-through, posing a safety risk.

Our team collaborated with their engineering department to specify a Vinyl Ester mini mesh grating solution. The smaller mesh size (19x19mm) was selected to mitigate the drop-through risk, while the superior chemical resistance of Vinyl Ester resin was critical for longevity in the aggressive acid conditions.

Outcome:

- After three years in service, the FRP mini mesh grating showed no signs of corrosion or degradation, far exceeding the lifespan of previous steel installations.

- The plant reported a significant reduction in foreign object debris (FOD) incidents due to the smaller mesh openings, improving overall safety and reducing operational disruptions.

- Maintenance costs associated with grating replacement were virtually eliminated, leading to substantial long-term savings.

- Installation was completed with 30% less labor time compared to steel, attributed to the lighter weight and ease of field fabrication of the FRP panels.

This case demonstrates the tangible benefits of specifying specialized FRP solutions like mini mesh grating for demanding industrial applications, showcasing superior performance, enhanced safety, and substantial cost savings over time.

Vendor Comparison and Customized Solutions

Selecting the right vendor for FRP mini mesh grating is as critical as choosing the material itself. A reputable supplier offers not only high-quality products but also comprehensive technical support and flexible customization options.

Key Factors for Vendor Selection:

- Quality Certifications: Look for vendors with ISO 9001 (Quality Management System) certification, and products that comply with relevant ASTM, EN, or other industry-specific standards. This assures consistent product quality and adherence to recognized manufacturing practices.

- Experience and Track Record: A long history of serving specific industries (e.g., petrochemical, marine) indicates a deep understanding of unique application challenges and proven solutions.

- Technical Support & Engineering Expertise: The ability to provide detailed load calculations, deflection analyses, CAD drawings, and installation guidance is crucial for complex projects.

- Customization Capabilities: The flexibility to provide non-standard panel sizes, specific resin systems, bespoke mesh configurations, or integrated structural components is a significant advantage.

- Lead Times and Fulfillment: Reliable delivery schedules and efficient logistics are essential for project timelines.

- Warranty and After-Sales Service: Clear warranty commitments and readily available customer support demonstrate a vendor's confidence in their product and commitment to client satisfaction.

Product Comparison: FRP Mini Mesh vs. Standard FRP Grating

| Feature | FRP Mini Mesh Grating | Standard FRP Grating (e.g., 38x38mm) |

|---|---|---|

| Mesh Opening Size | Smaller (e.g., 19x19mm, 25x25mm) | Larger (e.g., 38x38mm, 50x50mm) |

| Open Area Percentage | Lower (30-45%) | Higher (50-70%) |

| Preventing Small Item Drop-through | Excellent | Moderate to Low |

| Foot Comfort for Pedestrians | High (more solid walking surface) | Standard (can feel "graty") |

| Weight per Square Meter | Slightly higher (due to more material) | Lighter |

| Cost | Typically slightly higher (more resin/fiber) | Standard |

| Typical Applications | Pedestrian walkways, trench covers (where small items are a concern), food processing, accessibility ramps | General industrial platforms, elevated walkways, drainage covers |

Customized Solutions:

Reputable manufacturers offer extensive customization options to precisely meet project requirements:

- Specific Dimensions: Panels can be cut to exact sizes and shapes, including curved or irregular geometries, directly from the factory.

- Resin Systems: Choice of Orthophthalic, Isophthalic, Vinyl Ester, or Phenolic resins to match the specific chemical resistance, temperature, and fire retardancy requirements of the operational environment.

- Surface Finishes: Options include integral grit (quartz aggregate embedded for superior slip resistance), concave (molded-in slip resistance), or smooth surfaces.

- Color Matching: Grating can be pigmented to match corporate colors, designate safety zones, or blend with existing aesthetics.

- Integrated Fabrication: Services include pre-drilling, cutting for pipe penetrations, and edge banding for a complete, ready-to-install solution.

This level of customization ensures that the mini mesh grating solution is perfectly tailored, optimizing performance and installation efficiency.

Trustworthiness: FAQ, Lead Times, Warranty, and Support

Establishing trust with B2B clients requires transparency and robust commitments to product quality and customer service. This section addresses common inquiries and outlines crucial aspects of after-sales support.

Frequently Asked Questions (FAQ):

-

Q: What is the primary difference between GRP mini mesh grating and standard FRP grating?

A: The main difference lies in the mesh opening size. Mini mesh grating has smaller apertures (e.g., 19x19mm or 25x25mm) compared to standard FRP grating (e.g., 38x38mm). This smaller opening prevents small tools, parts, or personal items from falling through and provides a more comfortable walking surface, especially for those wearing high heels or requiring enhanced foot support. -

Q: What are the load-bearing capacities of mini mesh grating?

A: Load capacities vary significantly based on grating thickness, span length, and resin system. Generally, it is designed for heavy pedestrian traffic and light vehicular loads. Detailed load tables and engineering support are always provided to match specific project requirements and safety factors. -

Q: How is FRP mini mesh grating installed?

A: FRP grating is lightweight and easily cut using standard power tools with appropriate safety measures (e.g., diamond-tipped blades, dust extraction). Panels are typically secured to support structures using stainless steel clips and fasteners. Detailed installation guides are available from manufacturers. -

Q: What maintenance is required for mini mesh grating?

A: Minimal maintenance is required. Unlike metallic grating, it does not rust or require painting. Routine cleaning with soap and water is usually sufficient to remove dirt or industrial residues, restoring its appearance and slip resistance. -

Q: Can FRP mini mesh grating be used outdoors?

A: Absolutely. It is inherently UV stable with incorporated inhibitors and is resistant to weathering, salt spray, and extreme temperatures, making it ideal for outdoor and marine applications without degradation or fading.

Lead Time & Fulfillment Details:

For standard sizes and common resin systems, lead times typically range from 2-4 weeks. Customized orders, including specific dimensions, unique resin formulations, or high-volume requirements, may extend lead times to 4-8 weeks, depending on complexity and order size. Our logistics team works closely with clients to provide accurate lead time estimates and efficient delivery scheduling to minimize project delays.

Warranty Commitments:

All mini mesh grating products are backed by a comprehensive warranty, typically ranging from 5 to 10 years, covering manufacturing defects and ensuring compliance with stated specifications. This commitment reflects our confidence in the quality and durability of our composite solutions. Full warranty details are provided with every quotation and order.

Customer Support Information:

Our dedicated technical support team is available to assist with product selection, engineering calculations, installation guidance, and any post-sales inquiries. We provide expert consultation to ensure the optimal application and long-term performance of our FRP grating solutions. Contact information for technical assistance, sales, and customer service is readily available through our official channels.

Conclusion and Authoritative References

The continuous advancement in composite materials has positioned FRP mini mesh grating as an indispensable solution for modern industrial infrastructure. Its unparalleled resistance to corrosion, high strength-to-weight ratio, superior safety features, and minimal maintenance requirements deliver significant long-term value, enhancing operational efficiency and worker safety across diverse challenging environments. By offering customized solutions and upholding stringent quality standards, manufacturers ensure that these advanced gratings meet the precise demands of B2B applications, providing a robust, sustainable, and economically advantageous alternative to traditional materials.

References:

- ASTM International. "Standard Specification for Fiber-Reinforced Polymer (FRP) Grating Panels." ASTM D7105.

- NACE International (now AMPP). "Corrosion Control for the Chemical Process Industry." NACE Handbook.

- ISO 9001:2015. "Quality management systems — Requirements."

- Gay, D., & Strong, A. B. (2020). "Composite Materials Engineering: Volume 1 - Composites and Materials Science." CRC Press.

- Plastics Pipe Institute (PPI). "FRP Composites in Industrial Applications." Technical Resources.

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025