loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Micro Mesh Grating: Non-Slip, Corrosion-Resistant—Why Us?

Light Weight and High Strong FRP Micro Mesh Grating: Field Notes, Specs, and Real-World Use

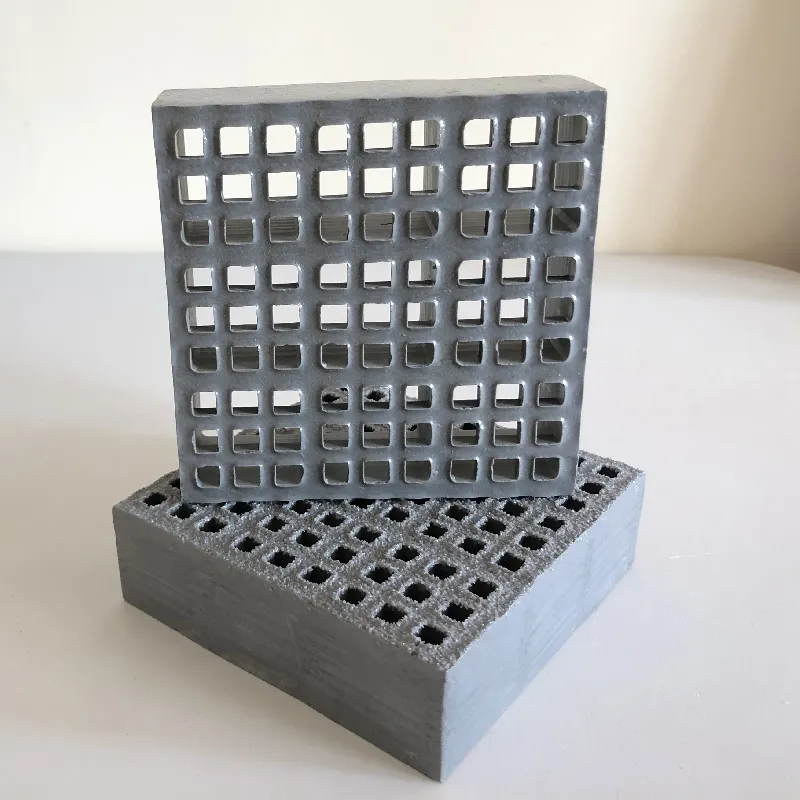

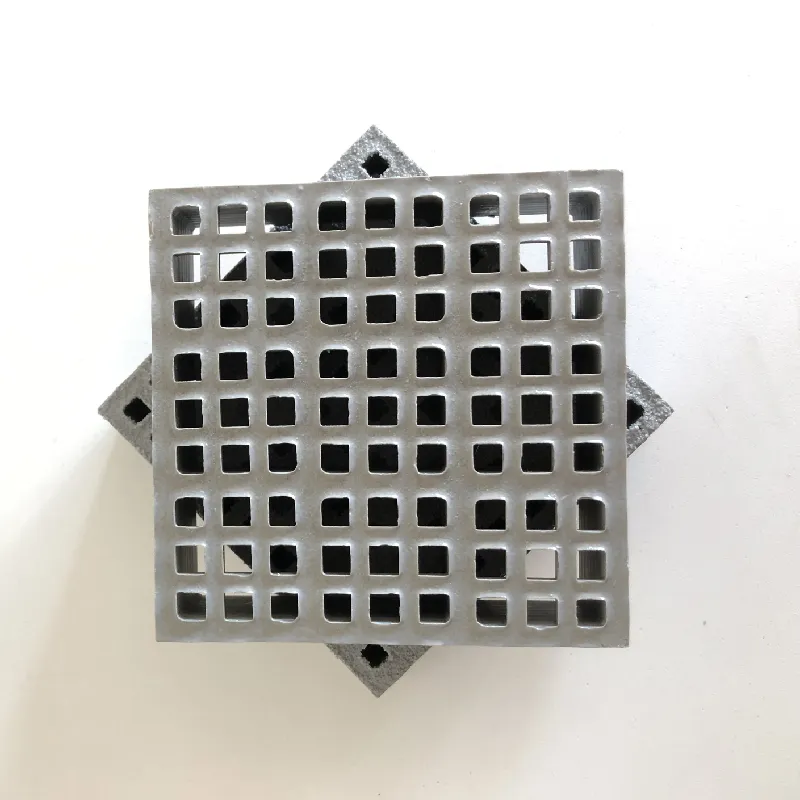

If you work around elevated walkways or corrosion-prone plants, you’ve likely heard the buzz about micro mesh grating. To be honest, the recent shift from steel to molded FRP isn’t just trend-chasing; it’s about safety, weight, and total lifecycle cost. The double-layer, micro‑porous design (some call it cross-grid) cuts the opening rate, so tools or fasteners are less likely to slip through. Many maintenance teams swear by the quieter, steadier feel under wheeled loads.

The model I’ve been reviewing on sites in Hebei and along several coastal facilities is light, tough, and oddly forgiving—reduced vibration on cart paths was noticeable. It seems that operators appreciate the anti-slip grit and the zero-rust factor more than they expected.

How it’s made (quick shop-floor tour)

Materials: E-glass rovings, isophthalic or vinyl ester resin (fire-retardant grade on request), UV stabilizers, pigments. Method: molded FRP with a double-layer, micro‑porous lattice that creates dense support ribs. Post-process: trimming, edge banding, embedded quartz-grit surface, sealing. Testing (typical): flexural per ASTM D790, surface burn per ASTM E84, slip per EN 13036‑4 (PTV), UV per ASTM G154, resin content per ASTM D2584. Service life in normal outdoor chemical exposure is commonly 20–25 years, though real-world use may vary.

Key specifications (typical)

| Panel thickness | ≈ 38 mm (double-layer micro-porous) |

| Mesh opening | ≈ 12–13 mm square; open area ≈ 12–18% |

| Standard panels | 1000 × 3000 mm, 1220 × 3660 mm (cut-to-size available) |

| Resin systems | Isophthalic polyester, vinyl ester; phenolic on request |

| Slip resistance | Grit top, PTV ≥ 36 wet (typical, EN 13036‑4) |

| Load guidance | Walkways/platforms ≈ 5 kN/m²; check project calc. |

| Temperature | -40 to 80 °C (polyester), up to ≈110 °C (VE) |

| Fire/Smoke | ASTM E84 Class A achievable with FR resin |

Where it shines

- High-altitude walkways and platforms—reduced drop-through risk for small parts.

- Wheeled traffic zones—less vibration; maintenance carts roll smoother.

- Chemical plants, water/wastewater, coastal facilities—FRP won’t rust, surprisingly low upkeep.

- Power and data-center rooftops—lightweight for retrofits, non-conductive option available.

This particular double-layer design is also favored where you need finer footing texture. Many customers say the quieter step noise is an unexpected bonus. Once crews get used to micro mesh grating, they rarely ask for checker plate again.

Vendor snapshot (quick compare)

| Vendor | Resins | Open area | Certs | Lead time | Warranty |

|---|---|---|---|---|---|

| ZJ Composites (Origin: No. 9, Xingyuan South St., Zaoqiang, Hengshui, Hebei, China) | ISO/VE; FR options | ≈12–18% | ISO 9001; test per ASTM/EN | ≈ 2–4 weeks | Up to 10 years (typical) |

| Competitor A (Generic) | ISO/VE | ≈15–20% | ISO 9001 | ≈ 3–6 weeks | 5–10 years |

| Competitor B (Generic) | ISO/VE/Phenolic | ≈10–16% | ISO 9001/14001 | ≈ 4–8 weeks | 5 years |

Customization and compliance

Color (RAL), panel size, resin system, surface (grit/concave), edge banding, and conductive/anti-static versions are available. For marine jobs, ask for build to ASTM F3059. Fire-retardant resins and low-smoke specs can be configured to meet ASTM E84 Class A. Slip targets are set around PTV ≥ 36 wet; verify on your substrate, because, actually, installation matters.

Field notes: two quick cases

Water treatment rooftop—Operators replaced corroded steel with micro mesh grating. Crew feedback: “lighter to lift, less bounce.” Measured wet PTV averaged 39–42 on the grit finish. Estimated maintenance cuts: ≈30% over five years.

Data center chiller yard—Wheeled carts and occasional pallet jacks. The double-layer lattice reduced vibration compared to open steel grating; noise dropped a few decibels (informal reading). No rust bleed on adjacent equipment—small win, big smiles.

Bottom line: if falling-object risk, corrosion, or wheel-induced vibration are on your punch list, micro mesh grating is a practical, safety-forward upgrade with predictable total cost of ownership.

References

- ASTM E84 – Standard Test Method for Surface Burning Characteristics of Building Materials: https://www.astm.org/e0084

- ASTM F3059 – Specification for Fiber-Reinforced Plastic (FRP) Grating for Marine Use: https://www.astm.org/f3059

- OSHA 29 CFR 1910, Walking-Working Surfaces: https://www.osha.gov/laws-regs/regulations/standardnumber/1910

- EN 13036-4 – Road and Airfield Surface Characteristics, Pendulum Test: https://standards.iteh.ai/catalog/standards/cen/9b7a1c6e-1d5a-4e2d-9d11-3b17bc5df29b/en-13036-4

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025