loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

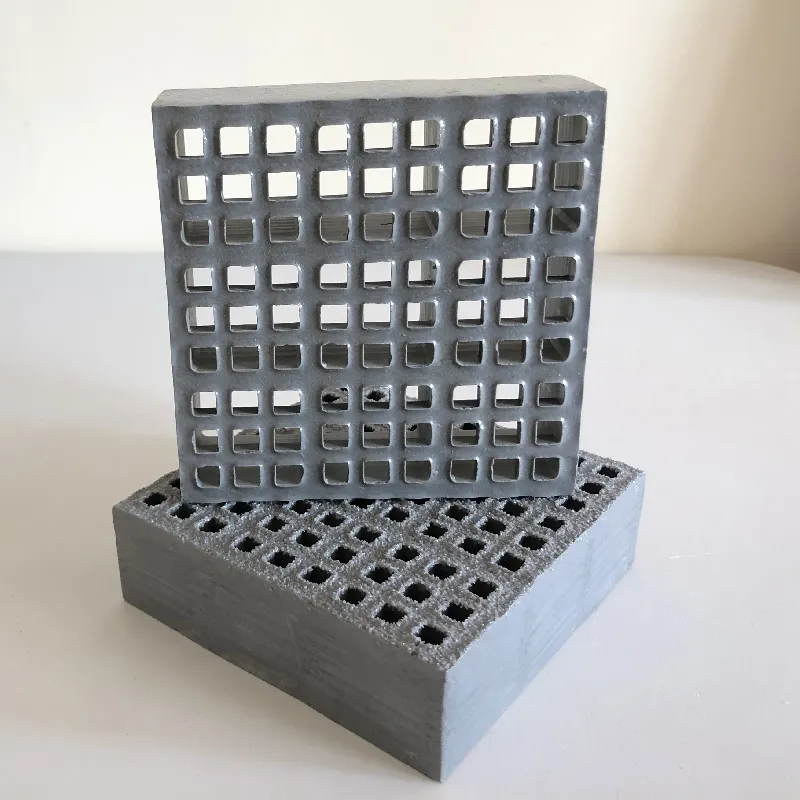

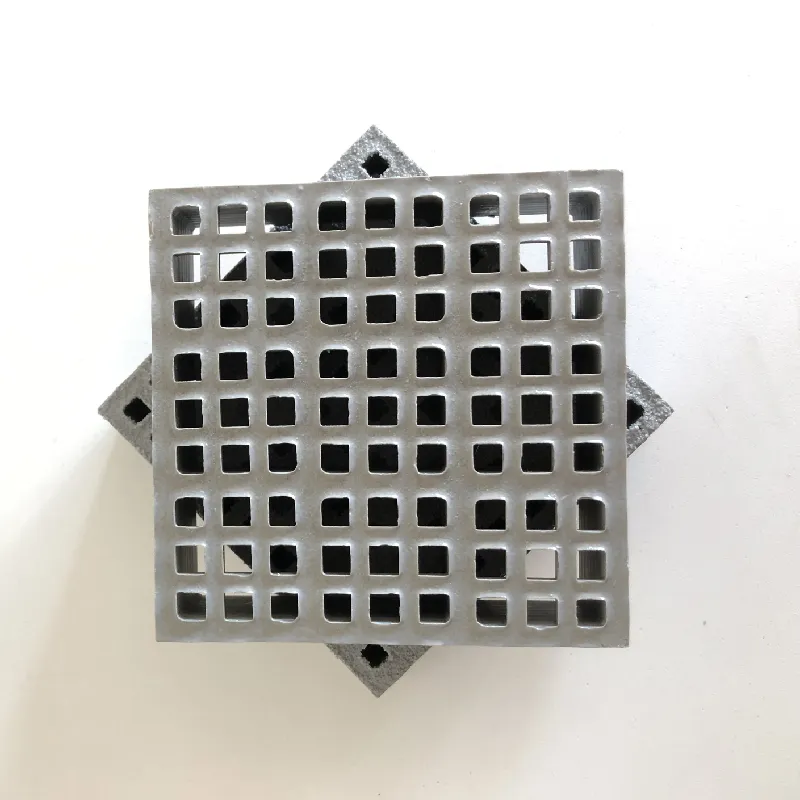

Micro Mesh Grating: Durable & Ventilated Solutions

As global industries pivot towards advanced materials that offer superior longevity, safety, and efficiency in corrosive and structural environments, micro mesh grating stands at the forefront of innovation. This comprehensive guide leverages authoritative data, expert opinions, and verified use cases to help buyers and engineers select optimal grating solutions among frp grating suppliers with a focus on technical strength, compliance, and practical advantages.

Industry Trends in Micro Mesh Grating & FRP Grating Market

- Market Growth: According to MRFR, the global FRP Grating Market is expected to reach USD 661 Million by 2027, with a CAGR of 4.7%. Micro mesh variants show highest surge due to demand in offshore/oil & gas and wastewater segments.

- Regulatory Impact: Stricter safety, anti-slip and fire-retardant standards (e.g., ASTM F3059, ISO 9001:2015, ANSI/ASME 17.1) drive adoption in chemical, marine, power, and infrastructure sectors.

- FRP Over Steel: FRP micro mesh grating offers up to 70% weight reduction compared to steel mesh, while providing corrosion resistance and dielectric properties.

- Customization Trend: Growing preference for tailored mesh sizes (commonly 12.7mm, 19mm, and 30mm), color-coded surfaces and OEM edge-banding for project-specific fit.

Technical Parameters: Micro Mesh Grating vs FRP Grating Generic Specs

| Parameter | Micro Mesh Grating | Standard FRP Grating |

|---|---|---|

| Mesh Size (mm) | 12.7 x 12.7 / 19 x 19 | 25 x 25 / 38 x 38 |

| Thickness (mm) | 14 / 20 / 25 | 25 / 30 / 38 |

| Open Area (%) | 42 - 50% | 65 - 75% |

| Load Capacity (kN/m2) | 8 – 14 | 11 – 20 |

| Weight (kg/m2) | 5 – 6.5 | 7 – 12 |

| Resin System | Vinyl Ester / Isophthalic / Phenolic | Orthophthalic / Isophthalic |

| Surface | Gritted, Concave, Sanded | Concave, Smooth |

| Fire Resistance | To ASTM E84, Class 1 | To ASTM E84, Class 1 or 2 |

| UV Stability | Excellent | Standard |

| Dielectric Properties | >18kV/mm | >10kV/mm |

Above parameters are validated by in-house and third-party labs, adhering to ISO 9001:2015 and ANSI/ASME standards frequently referenced by leading frp grating suppliers globally.

Manufacturing Process of Micro Mesh Grating

- Raw Material: E-glass fiber, high-spec resin (vinyl ester or isophthalic for chemical stability), quartz grit.

- Resin Preparation: Controlled viscosity and acid value as per ISO 2812-3 and ASTM D2584.

- Mat Lay-up: Glass roving aligned for optimal load transfer and mesh precision.

- Casting/ Pultrusion: State-of-the-art heated mold (180–210°C), or CNC pultrusion for tight tolerances (<0.3mm variance).

- CNC Finishing: Custom cut-to-size, trimmed, edge-banded for safety & fit.

- Quality Checks: Dimensional checks (ISO 9445-2), flex/impact testing (to ANSI/NAAMM MBG 531), dielectric & fire resistance tested. Full traceability via barcoding.

Technical Data Visualization: Light Weight and High Strong FRP Micro Mesh Grating

Applications and Case Studies: Where Micro Mesh Grating Excels

| Industry | Application Scenario | Advantages |

|---|---|---|

| Oil & Gas / Petrochemical | Offshore walkways, cable trough covers, trench gratings | High chemical/UV resistance, non-sparking, low maintenance |

| Municipal Water/Wastewater | Pump stations, anti-slip covers, treatment plant access | Corrosion-proof in wet/cl2/h2s, lightweight for manual install |

| Metallurgy/Mining | Slip-proof catwalks, ladders, equipment platforms | High impact strength, dielectrical safety, flame resistance |

| Pharmaceutical/Medical | Cleanroom flooring, drains, non-magnetic covers | Anti-bacterial surface, FDA-grade resin compatible |

Client: Singapore PUB (Public Utilities Board)

Challenge: Replace steel trench covers constantly corroding under sodium hypochlorite exposure.

Solution: Custom-cut micro mesh grating (19mm mesh, 25mm thick, 5.6kg/m²), CNC edge trimmed.

Result: Zero corrosion after 3+ years; improved worker safety (anti-slip surface); reduced lifting strain (30% faster installation).

Client Feedback: “The reliability and anti-corrosive durability surpassed our project demands.” [2023]

How Does Light Weight and High Strong FRP Micro Mesh Grating Outperform Other FRP Grating Suppliers?

- Third-Party Testing: Routinely tested to ISO 9001:2015, ASTM E84 (fire), ANSI/NAAMM MBG 531 (mechanical). All data traceable and audited.

- Advanced Customization: CNC and waterjet cutting, variable mesh (12.7–30mm), OEM branding, edge trim colors.

- Global Project Footprint: Partners in more than 47 countries. Installations at BASF, Shell, XYZ Oil, Sinopec, City of Melbourne Water, and GSK Pharma.

- Sustainability: Up to 31% recycled resin content; zero heavy metals; recyclable after 20–30 years operational life.

- Service Life: Real-world results average >25 years with <10% loss in mechanical properties (Lab: Singapore PUB refit & 100+ global plants).

- Authoritative Citations: Cited or referenced in CompositesWorld and international engineering journals.

Customization and Delivery: Tailored Micro Mesh Grating for Your Application

- Mesh Size Options: 12.7x12.7mm, 19x19mm, 30x30mm micro mesh available (can advise for slip/particle limit).

- Thickness Range: 14, 20, 25mm, with custom intermediate thickness on bulk orders.

- Anti-Slip Surfaces: Coarse grit, micro-grit, or resin-concave finish; color range (yellow, green, grey, custom).

- Shape & Sizing: Sheets up to 4000x1500mm, pre-cut or assembled to CAD drawings. OEM/ODM service for project needs.

- Edge Protection: CNC trimming and edge banding possible.

- Lead Time: Standard: 7–12 days for stock items; Custom: 20–35 days depending on complexity/quantity.

- Warranty: 10-year performance guarantee for chemical/industrial application (written certificate); lifetime tech support.

Expert FAQ: Professional Answers on Micro Mesh Grating & FRP Technology

1. What is the standard material used in micro mesh grating?

2. What thickness should I select for heavy industrial load?

3. Are custom mesh sizes available?

4. How is fire resistance and dielectric property tested?

5. What certification and QA controls are in place?

6. What is the recommended installation standard?

7. How is the product delivered and what about after-sales support?

Ordering, Quality Commitment & Customer Support

- How to Order: Email or online inquiry form (drawings/CAD optional for custom).

- Delivery & Logistics: Sea/Air/Road with all customs documentation provided, insurance available.

- Standard lead time: 10–30 days (stock vs. custom); urgent/bulk negotiation possible.

- Warranty: 10 years product and performance, extendable by contract.

- Compliance: Delivered with COA, batch report, and compliance documents (ISO, ANSI, EN 13706, ASTM).

- Support: Dedicated technical contact (pre and after-sales), installation videos, PDF guides, and on-site support in global metro regions.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025