loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

marine grating

Marine Grating An Essential Component in Maritime Safety and Engineering

Marine grating is an indispensable element in the maritime industry, primarily utilized for safety and functionality in various engineering applications. Designed to enhance traction and prevent slips in environments with high foot traffic or hazardous conditions, marine grating serves as a reliable solution for docks, piers, and boat ramps.

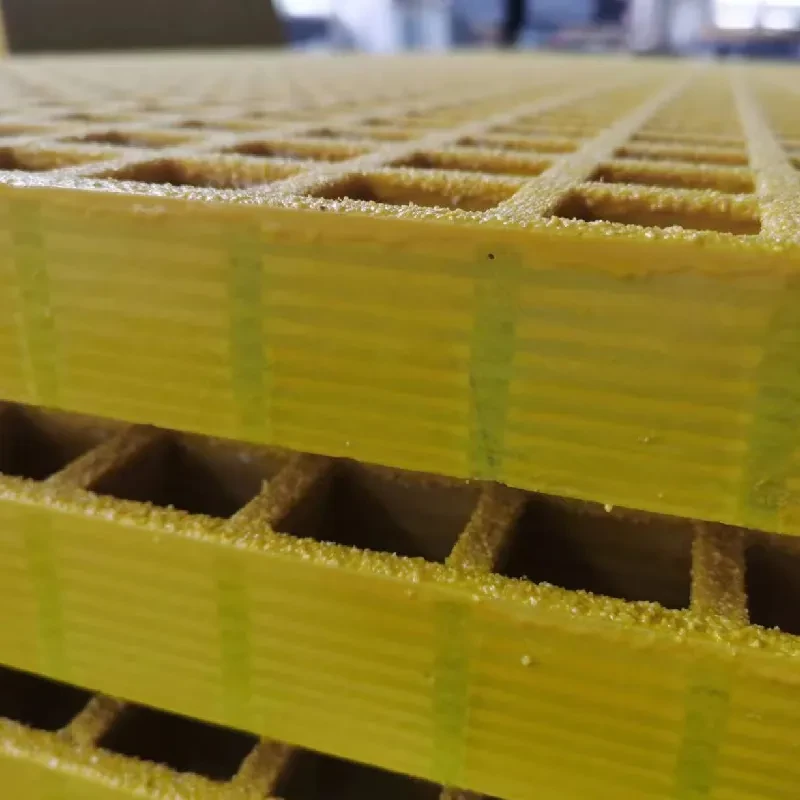

One of the primary materials used in marine grating is fiberglass reinforced plastic (FRP). This material is particularly popular due to its lightweight nature, corrosion resistance, and durability, making it ideal for harsh marine environments. Unlike traditional steel grating, which can rust and deteriorate due to constant exposure to saltwater and other corrosive elements, FRP marine grating maintains its integrity over time, minimizing maintenance costs and downtime.

Moreover, the slip-resistant surfaces of marine grating are designed to provide enhanced footing, even in wet or slippery conditions, thereby significantly reducing the risk of accidents

. This feature is crucial in marine settings where the combination of water, grease, and heavy foot traffic can create perilous situations. The grating's open design also allows for water drainage, further reducing slip hazards and facilitating efficient water flow on docks and walkways.marine grating

In addition to safety, marine grating plays a vital role in the structural integrity of marine constructions. Used as flooring for walkways, platforms, and access bridges, it provides substantial load-bearing capabilities while remaining lightweight. This characteristic is essential for marine engineering applications where weight considerations are paramount, such as in the construction of floating docks or vessels.

The versatility of marine grating extends beyond traditional marine applications. It is also used in wastewater treatment facilities, chemical plants, and other industrial environments where corrosion resistance and slip prevention are critical. Its adaptability to various environments makes it a reliable choice for engineers and safety managers across different sectors.

Furthermore, the environmental impact of marine grating is an important consideration. Manufacturers are increasingly exploring sustainable practices, incorporating recycled materials into their products. This trend not only reduces the carbon footprint of marine construction but also aligns with the broader movement towards sustainability in industrial applications.

In conclusion, marine grating stands as a vital component in ensuring safety and efficiency in maritime and industrial settings. Its unique properties, including corrosion resistance, slip prevention, and lightweight design, make it an optimal choice for a wide range of applications. As the maritime industry continues to evolve, the role of marine grating will undoubtedly remain crucial in promoting safety and operational effectiveness.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025