loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

marine grating

Marine Grating A Deep Dive into Its Importance and Applications

Marine grating, an essential component in various maritime applications, plays a critical role in enhancing safety, accessibility, and efficiency in marine environments. Whether utilized in shipbuilding, offshore platforms, or waterfront facilities, the significance of marine grating cannot be overstated. This article delves into the various aspects of marine grating, including its materials, design, applications, and benefits.

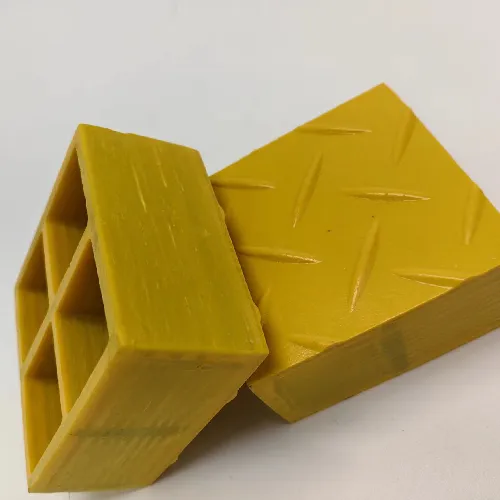

At its core, marine grating is crafted from materials that can withstand the harsh conditions of marine environments. Common materials include fiberglass reinforced plastic (FRP), aluminum, and stainless steel. Fiberglass grating, in particular, has gained popularity due to its lightweight nature, resistance to corrosion, and durability. This makes it an ideal choice for applications exposed to saltwater, chemicals, and UV rays, often found in coastal regions and offshore facilities.

The design of marine grating is also crucial. It is engineered to provide optimal traction while ensuring safety on surfaces that may become wet or slippery. The use of various patterns and surface textures helps to minimize the risk of slips and falls, making it an ideal flooring option for decks, walkways, and staircases on ships and platforms. Furthermore, marine grating is often designed with drainage capabilities, allowing water to flow through the grating and preventing the accumulation of liquids that can create hazardous conditions.

One of the prominent applications of marine grating is in the offshore oil and gas industry. Offshore rigs and platforms require durable and reliable materials for walkways and operational areas, where safety is paramount. Marine grating not only provides the necessary support and stability but also contributes to weight savings, which is crucial for the structural integrity of floating platforms. Its resistance to corrosion ensures that the grating maintains its integrity over time, even in the most challenging environments.

marine grating

In addition to the oil and gas sector, marine grating is extensively used in the construction of docks, piers, and marinas. These facilities require a reliable surface that can endure high foot traffic, vessel movements, and exposure to the elements. Marine grating offers a practical solution that combines strength with lightweight properties, allowing for easier installation and maintenance. Additionally, the open design of the grating permits water to flow freely, reducing the risk of erosion and damage to the underlying structures.

Another noteworthy application of marine grating is in water treatment facilities. As these facilities often operate in coastal areas and must manage both fresh and saltwater, the durability and corrosion resistance of marine grating become vital. Using marine grating in these settings allows for efficient maintenance access, facilitating the regular upkeep of equipment and ensuring optimal performance.

The environmental benefits of marine grating should also be highlighted. The longevity and durability of materials like fiberglass contribute to reduced waste generation. Furthermore, the production processes for many marine grating materials prioritize sustainability, aligning with the growing focus on eco-friendly practices in maritime operations.

In conclusion, marine grating is an indispensable element in a variety of maritime applications. Its robust construction, safety features, and adaptability make it crucial for ensuring the safety and efficiency of marine environments. As industries continue to innovate and seek more sustainable practices, the role of marine grating will undoubtedly evolve, remaining at the forefront of maritime engineering solutions. Whether in offshore platforms, dock construction, or water treatment facilities, marine grating is indeed a foundational component in the maritime world.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025