loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Innovative Designs in Marine Grating for Enhanced Performance and Durability

Marine Grating An Overview of Its Importance and Applications

Marine grating, often referred to in the context of reinforced grating systems for marine environments, plays a crucial role in various maritime applications ranging from industrial facilities to recreational areas. Its structural integrity, corrosion resistance, and safety features make it indispensable in environments where conventional materials might fail due to the harsh conditions often found at sea.

Composition and Properties

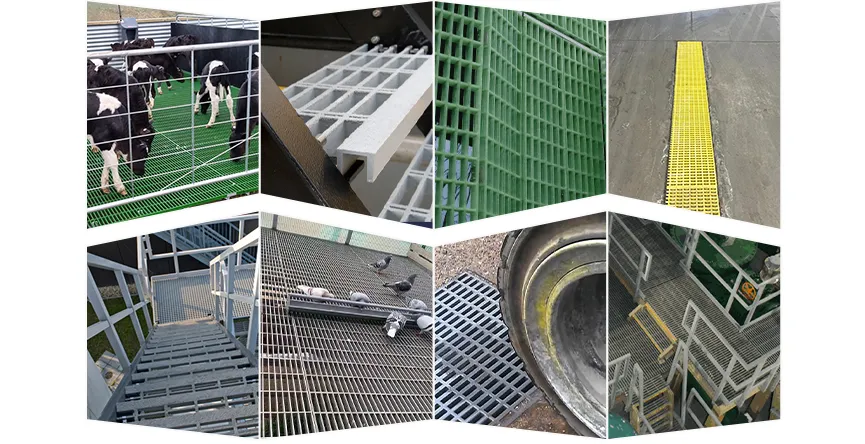

Marine grating typically consists of fiberglass or metal, chosen for their high resistance to corrosion, particularly in saline conditions. Fiberglass reinforced plastic (FRP) grating, in particular, is favored for its lightweight and durable properties. It is resistant to rotting, rusting, and other forms of degradation that can occur when traditional materials like steel are exposed to salty water and humid air. Metal gratings made from stainless steel or aluminum also provide significant benefits due to their strength and ability to withstand substantial loads, making them suitable for heavy traffic areas near docks and piers.

The open-grid design of marine grating allows for the efficient drainage of water, reducing the potential for slip hazards. This feature is particularly significant in wet environments, making it an ideal choice for walkways, stairways, and platforms around marine installations.

Applications in Marine Environments

The applications of marine grating are varied and extensive. In commercial settings, it is widely used in shipyards, aquaculture facilities, marine construction, and oil platforms. In shipyards, for instance, the ability to withstand heavy machinery and equipment while also providing a non-slip surface is critical for worker safety and efficiency.

marine grating

In recreational environments, marine grating can be found on docks, boat ramps, and coastal walkways

. Its design not only ensures safety for those engaging in maritime activities but also enhances the aesthetic appeal of waterfront facilities. Moreover, the lightweight nature of grating allows for easier installation and maintenance, which is a significant consideration for public structures.Advantages Over Traditional Materials

One of the primary advantages of marine grating over traditional materials is its longevity. Given the constant exposure to harsh marine conditions, using materials that require minimal maintenance is essential. Traditional metal grates often succumb to corrosion over time, leading to costly replacements and downtime. In contrast, the durability of fiberglass and specially treated metals used in marine grating extends its lifespan significantly.

Furthermore, the installation of marine grating can be highly customized, accommodating various designs and loads to meet specific project requirements. This versatility ensures that contractors can effectively address structural needs while providing a safe, robust solution that complies with maritime regulations.

Future Trends

As we move into a future increasingly focused on sustainability, the production and application of marine grating are also evolving. Innovations in composite materials are being developed to enhance performance and reduce environmental impact. Additionally, the trend towards more eco-friendly construction methods is leading to the design of marine grating that integrates recycled materials, promoting a circular economy.

In conclusion, marine grating represents a critical component within marine engineering and construction, offering safety, durability, and versatility. As oceanic activities continue to grow, the demand for effective and resilient solutions like marine grating will only increase, ensuring its place as a fundamental element in maritime infrastructure.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025