loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Innovative Applications of Marine Grating in Coastal Engineering and Marine Structures

The Fascinating World of Marine Grating

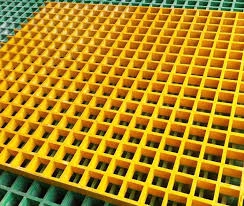

Marine grating, often referred to as fiberglass grating or composite grating, is an innovative and essential component widely used in coastal and marine environments. This versatile material, known for its strength, corrosion resistance, and lightweight nature, provides solutions for various applications in industries ranging from maritime construction to environmental conservation. In this article, we delve into the characteristics, benefits, and applications of marine grating, illuminating its critical role in modern marine infrastructure.

Understanding Marine Grating

Marine grating is primarily composed of fiberglass reinforced polymers (FRP), which makes it significantly more resistant to the corrosive effects of saltwater and other harsh marine conditions compared to traditional materials like steel or aluminum. It is designed with a grid-like structure that enhances its durability while allowing the passage of light and air. This perforated design also provides excellent slip resistance, making it ideal for high-traffic areas such as docks, walkways, and platforms.

The manufacturing process of marine grating involves impregnating glass fibers with a thermosetting resin, creating a composite material that combines the tensile strength of glass with the flexibility of resin. This results in a lightweight yet robust product suitable for various marine applications.

Benefits of Marine Grating

1. Corrosion Resistance One of the most significant advantages of marine grating is its ability to withstand corrosion. Unlike metal grates, which can rust and deteriorate rapidly in salty or humid environments, fiberglass grating remains inert and intact, resulting in lower maintenance costs and longer service life.

2. Lightweight Nature Marine grating is much lighter than traditional materials, making it easier to transport and install. This characteristic not only reduces labor costs but also minimizes the need for heavy equipment during installation.

3. Slip Resistance The textured surface of marine grating ensures safety in wet or slippery conditions. This feature is particularly crucial in environments where workers are exposed to water and need stable footing on walkways, poolsides, and similar areas.

4. Versatility in Design Marine grating can be manufactured in various colors, sizes, and configurations to suit specific project needs. This adaptability makes it an efficient choice for architects and engineers seeking to blend functionality with aesthetic appeal in marine structures.

marine grating

5. Environmental Considerations With increasing emphasis on sustainability, marine grating offers an eco-friendly solution. It can be made from recycled materials and promotes longevity, resulting in less waste and environmental impact over its lifespan.

Applications of Marine Grating

The applications of marine grating are diverse and widespread, reflecting its utility across various sectors

- Docks and Marinas Marine grating is commonly used in the construction of walkways, loading platforms, and pedestrian access areas in docks and marinas, providing safe and durable surfaces that resist the challenges of the marine environment.

- Industrial Facilities Many industries that operate near oceans or inland water bodies use marine grating for platforms, stairs, and catwalks. The chemical resistance of fiberglass makes it an ideal choice for facilities handling hazardous materials.

- Water Treatment Plants Marine grating can be found in water treatment facilities where it offers a reliable surface for maintenance personnel and equipment while withstanding the corrosive nature of water and chemicals used in treatment processes.

- Aquaculture In aquaculture operations, marine grating is utilized for habitat structures, walkways, and even fish pens. Its durability ensures that it can withstand constant exposure to water without degrading.

- Coastal Structures From bridges to seawalls, the resilience of marine grating is leveraged in coastal engineering to support structures that confront the relentless forces of tides and weather.

Conclusion

Marine grating stands out as a critical innovation in the field of engineering and construction, especially in areas impacted by sea and salt. Its unique properties, combined with a broad range of applications, not only enhance safety but also contribute to the longevity of marine infrastructures. As industries evolve and the demand for sustainable materials increases, marine grating will likely play a pivotal role in shaping the future of coastal and marine development, ensuring that our coastal ecosystems are preserved and protected for generations to come.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025