loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Effective Safety Solutions for Industrial Machine Protection and Guarding Systems

Machine Guarding Systems Ensuring Safety in the Workplace

In today's fast-paced industrial environments, the imperative for maintaining safety standards cannot be overemphasized. One of the fundamental components of workplace safety is machine guarding systems. These systems are designed to prevent accidents and injuries by providing a physical barrier between humans and machines, thereby safeguarding employees while they perform their tasks.

Machine guarding systems can take various forms, including fixed guards, interlock guards, adjustable guards, and presence-sensing devices

. Each type serves a specific purpose and is crucial in mitigating risks associated with operating machinery.Fixed Guards are permanently attached to machines and serve as the first line of defense against potential hazards. These guards are typically made from sturdy materials that can withstand wear and tear from machinery operation while providing a dependable barrier. For example, a fixed guard might encase the moving parts of a machine, such as gears or belts, ensuring that workers cannot access these hazardous areas during operation.

Interlock Guards play a crucial role in preventing machines from operating when the guard is not in place. These systems are equipped with sensors that detect whether a guard is properly secured. If a worker attempts to operate the machine without the guard in position, the device will either not turn on or will shut down if it is already running. This type of guard is particularly important in situations where machinery must be accessed frequently for maintenance or loading purposes.

Adjustable Guards offer flexibility for operators who need to manage varying sizes of materials. These guards can be repositioned without tools, allowing workers to customize the guarding for different tasks. However, it’s essential that training is provided to workers to ensure these guards are adjusted correctly and securely before operation begins.

machine guarding systems

Presence-sensing devices include photoelectric sensors, light curtains, and pressure-sensitive mats that detect the presence of a worker within a designated safety zone. If an employee enters this area while the machine is in operation, the device will trigger an automatic shutdown, protecting the worker from potential harm. These systems are particularly useful in complex environments where traditional guards may not be feasible.

While the implementation of machine guarding systems is crucial, it is only one part of a comprehensive safety strategy. Regular training for employees on the correct use of guards is essential for maintaining a safe work environment. Workers must understand the importance of these systems, how they function, and the risks involved with machinery. It is also vital for organizations to foster a safety culture where employees feel empowered to report issues regarding machine guarding, whether it's a malfunction or a potential hazard.

Periodic risk assessments are also essential for ensuring that the machine guarding systems remain effective. As workplaces evolve, new equipment may be introduced, or existing machinery may be modified. Organizations must routinely evaluate their guarding systems to ensure they meet current safety standards and remain relevant to the equipment in use. Adapting to changes in technology and operation allows for enhanced safety and reduced accident potential.

Moreover, compliance with safety regulations set by governing bodies, such as the Occupational Safety and Health Administration (OSHA) in the United States, is non-negotiable. These regulations often outline specific requirements for machine guarding, and adherence not only promotes safety but also protects organizations from legal liabilities.

In conclusion, machine guarding systems are vital components of workplace safety designed to protect workers from potential hazards associated with machinery. Fixed guards, interlock guards, adjustable guards, and presence-sensing devices each play crucial roles in this safety mechanism. However, their effectiveness relies heavily on ongoing employee training, routine assessments, and compliance with safety regulations. By prioritizing machine guarding systems and fostering a safety-conscious culture, organizations can significantly reduce workplace injuries and create a safer environment for all employees. Investing in these systems not only safeguards human life but also enhances productivity, as employees can work without the constant fear of accidents. Therefore, every organization should recognize the importance of machine guarding systems in their operations and practices.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

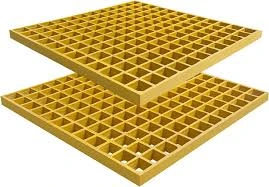

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025