loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

machine guarding systems

Understanding Machine Guarding Systems Ensuring Safety in the Workplace

In modern industrial settings, the safety of workers is paramount, and one effective way to ensure this is through the implementation of machine guarding systems

. These systems are designed to protect employees from various hazards associated with machinery, thereby minimizing the risk of injuries and fatalities. As industries continue to evolve, the importance of machine guarding systems cannot be overstated.Machine guarding systems primarily serve to create a barrier between workers and moving parts of machinery, which could cause serious injuries such as lacerations, crushing, or even amputation. The Occupational Safety and Health Administration (OSHA) outlines specific guidelines and regulations that employers must follow to ensure operational safety. These standards require that all machines with dangerous parts be equipped with appropriate guarding measures.

There are several types of machine guards that can be used, depending on the specific machinery and hazards involved. Fixed guards are immovable and provide permanent protection. They are ideal for machines that do not require frequent access to the operator. Adjustable guards, on the other hand, can be moved or adjusted to accommodate various tasks while still providing a level of protection. Lastly, self-adjusting guards are designed to move into place as the machine operates, ensuring that only authorized personnel can access the hazardous area.

machine guarding systems

In addition to physical barriers, machine guarding systems also incorporate safety devices such as sensors, emergency stop buttons, and interlocks. These features are crucial in modern automated environments, providing an additional layer of safety. For instance, light curtains can be used to detect the presence of an individual in a hazardous area and can immediately shut down the machine if an intrusion occurs.

Regular maintenance and training are essential components of an effective machine guarding system. Employers should ensure that guards are routinely inspected for any signs of wear or damage, ensuring they remain effective. Furthermore, training employees on the importance of machine safety and proper use of guarding systems can foster a culture of safety within the workplace.

In conclusion, machine guarding systems play a critical role in protecting workers from the dangers posed by machinery. By understanding and implementing proper guarding measures, organizations can significantly reduce the risk of workplace injuries. As technology progresses and industrial operations become more complex, prioritizing the safety of workers through effective machine guarding practices will continue to be a crucial element of a responsible and productive work environment.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

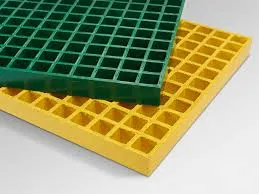

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025