loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

liquid filter vessel

The Importance and Functionality of Liquid Filter Vessels

In industrial applications, the need for efficient filtration of liquids is paramount. Liquid filter vessels play a critical role in ensuring that liquids are processed safely and efficiently, free from unwanted contaminants that could compromise product quality or operational efficiency. These vessels are designed to hold filter media, allowing for the separation of solid particles from liquids, thereby facilitating a range of processes across various industries.

Understanding Liquid Filter Vessels

A liquid filter vessel is essentially a container that houses a filtration system. The design and construction of these vessels can vary significantly depending on the application, making them versatile components in sectors such as pharmaceuticals, food and beverage, chemicals, and wastewater treatment. The fundamental principle of operation involves passing a liquid through the filter medium, which traps solid particles while allowing the filtered liquid to flow through.

Liquid filter vessels can employ different types of filtration techniques, including mechanical, chemical, and biological methods. Mechanical filters utilize physical barriers to block larger particles; chemical filters involve the use of reactive materials that bind with contaminants, while biological filters rely on microorganisms to decompose or absorb harmful substances.

Types of Liquid Filter Vessels

There are several types of liquid filter vessels, each suited for specific applications

1. Bag Filters Commonly used in industrial applications, bag filters are made of permeable fabrics that capture particles as liquid flows through them. They are ideal for applications requiring high flow rates and can be easily replaced when clogged.

liquid filter vessel

2. Cartridge Filters These are cylindrical filters that contain filter media in either disposable or reusable formats. Cartridge filters are versatile and are used in scenarios where space is limited, and high filtration precision is needed.

3. Strainers These are simple filtration devices that use a mesh screen to remove larger particles. Strainers are often employed in pipelines and are crucial for protecting pumps and valves from damage caused by debris.

4. Disc Filters Comprising multiple discs stacked together, these filters offer a high surface area for filtration and are effective in removing fine particles from liquids. Disc filters are particularly useful in the wastewater treatment industry.

Advantages of Liquid Filter Vessels

The advantages of using liquid filter vessels extend beyond just improving liquid quality. Firstly, they enhance operational efficiency. By removing unwanted particulates, filter vessels help to prevent damage to pumps and machinery, which can lead to costly downtimes. Moreover, the recycling of process water becomes more feasible, promoting sustainability within industrial operations.

Secondly, liquid filter vessels contribute to safety. In sectors like pharmaceuticals and food production, ensuring that products are contaminant-free is critical. Regular use of filter vessels minimizes the risk of contamination, safeguarding product integrity and compliance with health regulations.

Conclusion

In conclusion, liquid filter vessels are integral to many industrial processes, serving as the backbone of liquid filtration systems. Their ability to effectively separate solid contaminants from liquids not only enhances product quality but also improves operational efficiency and safety across various sectors. As industries continue to innovate and adapt to more stringent regulations and environmental concerns, the role of liquid filter vessels will likely expand, underscoring the importance of filtration technology in maintaining the integrity and safety of products and processes. Investing in high-quality liquid filter vessels is crucial for businesses aiming to optimize performance and ensure compliance in today’s competitive market.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

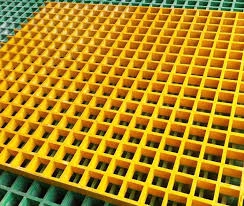

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025