loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

liquid filter vessel

Understanding Liquid Filter Vessels Essential Components for Efficient Filtration

In various industries, the filtration of liquids is a critical process that ensures the quality and purity of products. Liquid filter vessels play a pivotal role in this filtration system, serving as containers where liquid is filtered to remove impurities, suspended solids, and contaminants. This article delves into the significance, design, and operational aspects of liquid filter vessels.

What is a Liquid Filter Vessel?

A liquid filter vessel is a specifically designed container used in industrial applications to filter liquids. It typically incorporates several filtration elements, including filter bags, cartridges, and other media, to capture contaminants as the liquid flows through. Designed to withstand high pressure and various chemical compositions, these vessels come in numerous sizes and configurations to cater to diverse operational requirements.

Importance of Filtration

Effective filtration is crucial in sectors like pharmaceuticals, food and beverage, chemical processing, and water treatment, among others. In these industries, the presence of particulates can lead to product contamination, equipment damage, and regulatory compliance issues. By removing these impurities, liquid filter vessels not only safeguard product integrity but also enhance the efficiency and longevity of downstream processes.

Design Considerations

The design of a liquid filter vessel is influenced by several factors, including the type of liquid being filtered, the nature of the contaminants, the required flow rate, and the operational environment. Manufacturers typically offer various materials such as stainless steel, carbon steel, and plastics to ensure compatibility with the liquid's chemical properties.

Key components of a liquid filter vessel include

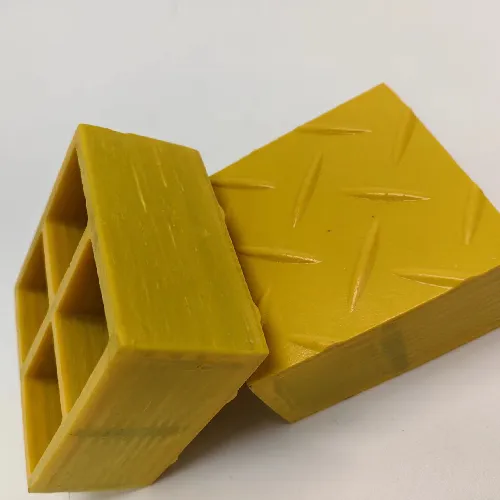

liquid filter vessel

1. Inlet and Outlet Connections These facilitate the entry and exit of liquids. Proper sizing and positioning are crucial to ensure smooth flow and prevent backpressure.

2. Filtration Media Depending on the application, filter bags or cartridges made from specific materials are used to capture particulate matter. The choice of media affects filtration efficiency and the frequency of maintenance.

3. Pressure Relief Valves These are essential for safety, allowing for the release of excess pressure within the vessel, thereby preventing potential hazards.

4. Access Hatches Regular maintenance and replacement of filter media are necessary for optimal performance, making access hatches an indispensable design feature.

Operational Efficiency

To ensure the liquid filter vessel operates at peak efficiency, regular monitoring and maintenance are paramount. Operators should establish a routine check-up schedule to assess filter conditions, flow rates, and any potential leaks. Additionally, using automatic sedimentation systems can enhance efficiency by allowing continuous operation while maintaining the quality of the filtration process.

Conclusion

Liquid filter vessels are essential components in numerous industrial applications, ensuring the purity and safety of liquids. Their design and functionality are tailored to meet the demanding requirements of various sectors, underscoring their importance in maintaining product quality and operational efficiency. As industries evolve and face new challenges, advancements in filter vessel technology will continue to play a crucial role in their success.

Understanding the significance of these vessels encourages industries to invest in high-quality systems that align with their specific filtration needs, ultimately contributing to improved product reliability and performance.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025