loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Innovative Solutions for Pentair FRP Vessels in Water Treatment Applications

Pentair FRP Vessels A Comprehensive Overview

Pentair, a global leader in water treatment and fluid management solutions, provides a diverse range of products, including fiberglass reinforced plastic (FRP) vessels. These vessels are integral to various industrial applications, where durability, corrosion resistance, and lightweight properties are paramount. This article delves into the features, advantages, and applications of Pentair FRP vessels, highlighting why they are a preferred choice in many sectors.

Understanding FRP Technology

Fiberglass reinforced plastic (FRP) is a composite material made of a polymer matrix reinforced with fibers, usually glass. The combination of these materials results in a product that is both strong and lightweight. Pentair’s FRP vessels leverage this technology to provide exceptional durability and resistance to harsh environmental conditions. The advanced manufacturing techniques employed ensure that these vessels meet stringent industry standards, making them suitable for various applications such as water treatment, chemical processing, and more.

Key Features of Pentair FRP Vessels

1. Corrosion Resistance One of the standout features of FRP vessels is their outstanding resistance to corrosion. Unlike traditional materials such as steel or concrete, which can degrade when exposed to harsh chemicals or moisture, Pentair’s FRP vessels maintain their structural integrity over time. This characteristic is particularly beneficial in industries where chemical exposure is a norm.

2. Lightweight Design The lightweight nature of FRP vessels facilitates easier handling and installation. This can lead to reduced labor costs and quicker project timelines, making them an ideal choice for many applications. The reduced weight also helps in minimizing transportation costs, further enhancing their economic viability.

3. Customizable Options Pentair offers a wide range of customizable options for their FRP vessels. Customers can choose various sizes, shapes, and fittings to meet specific requirements. This flexibility is crucial in applications where space constraints or unique operational needs exist.

4. Longevity and Maintenance FRP vessels are designed for long-term use, significantly reducing the need for frequent maintenance or replacement. Their resilience to environmental factors means that they can perform reliably for many years, leading to lower lifecycle costs.

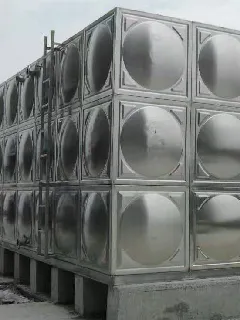

pentair frp vessels

Applications of Pentair FRP Vessels

Pentair FRP vessels find applications across a variety of industries

- Water Treatment In municipal and industrial water treatment processes, these vessels are used for filtration, softening, and chemical dosing. Their corrosion resistance ensures that they operate effectively in environments with high salinity or aggressive chemicals.

- Chemical Processing The chemical industry often requires robust containment solutions for various substances. FRP vessels are ideal for holding corrosive chemicals, ensuring safety and compliance with regulations.

- Oil and Gas In the oil and gas sector, FRP vessels are used in various capacities, from storing hazardous materials to separating and processing different substances.

- Food and Beverage The durable and non-reactive nature of FRP vessels makes them suitable for the food and beverage industry, where hygiene and material integrity are paramount.

Conclusion

Pentair’s commitment to quality and innovation is evident in its FRP vessel offerings. By combining advanced materials with expert engineering, Pentair provides solutions that meet the challenges of modern industrial applications. The unique features of these vessels—corrosion resistance, lightweight design, customizability, and longevity—position them as an ideal choice for industries seeking reliable, efficient, and cost-effective solutions. As industries continue to evolve, the role of FRP vessels in enhancing operational efficiency and safety will undoubtedly grow, making them an essential component in the future of fluid management and water treatment.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025