loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

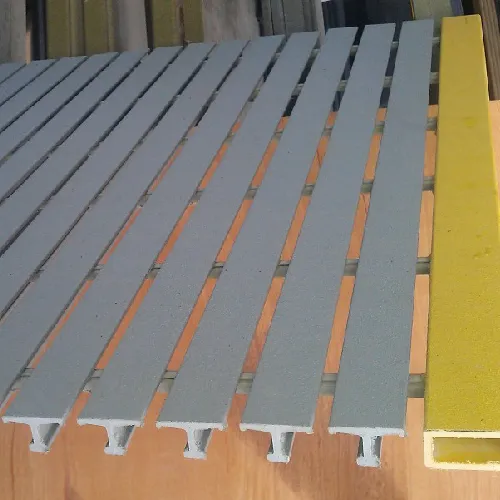

Innovative Moulded Fibreglass Grating Solutions for Enhanced Structural Support and Durability

The Benefits of Moulded Fibreglass Grating

Moulded fibreglass grating has emerged as an innovative and versatile solution for various industrial and commercial applications, offering numerous advantages over traditional materials like steel and wood. Constructed through a process of polymerization, moulded fibreglass grating is composed of glass fibres and resin, resulting in a lightweight, durable product that can withstand demanding environments. This article explores the key benefits and applications of moulded fibreglass grating.

Durability and Strength

One of the standout features of moulded fibreglass grating is its exceptional durability. This material is highly resistant to corrosion, making it an ideal choice for environments that are exposed to harsh chemicals, moisture, and saltwater. Unlike steel grates that may rust or degrade over time, fibreglass grating maintains its structural integrity even in the most challenging conditions. Furthermore, it possesses a high strength-to-weight ratio, which allows for reduced load-bearing requirements without compromising safety or effectiveness.

Safety Considerations

Another critical advantage of moulded fibreglass grating is its non-slip surface

. The texture of the grating is specifically designed to provide excellent traction, reducing the risk of slips and falls, particularly in wet or slippery conditions. This is vital in industrial settings, such as factories, marine facilities, and chemical plants, where safety is a top priority. The incorporation of safety features like colour-coding and luminous strips enhances visibility and awareness in low-light environments.Lightweight and Easy to Install

Moulded fibreglass grating is significantly lighter than steel or concrete alternatives, which simplifies transportation and installation. Its lightweight nature decreases the need for heavy machinery, reducing labour costs and installation time. The ease of handling and cutting the grating to size allows for greater flexibility in construction projects, enabling custom solutions that meet specific site requirements.

moulded fibreglass grating

Low Maintenance Costs

The longevity and resistance to environmental factors of moulded fibreglass grating translate to lower maintenance costs over time. Unlike metal grates that require regular painting or treatment to prevent corrosion, fibreglass grating typically only needs occasional cleaning to maintain its appearance and functionality. This low-maintenance characteristic contributes to significant savings for businesses and facility managers in the long run.

Versatile Applications

Moulded fibreglass grating is widely used across various industries, including aerospace, food and beverage, pharmaceuticals, and waste management. Its ability to handle heavy loads while resisting harsh environments makes it suitable for numerous applications, such as walkways, platforms, stair treads, and drainage covers. The product can also be custom fabricated into different shapes and sizes, catering to unique project requirements.

Environmental Benefits

In today’s eco-conscious world, the environmental impact of materials is an important consideration. Moulded fibreglass grating is increasingly produced with sustainability in mind. Many manufacturers utilize recycled materials in their resin formulations and adhere to environmentally friendly production processes. Additionally, the product’s longevity means less frequent replacement, further reducing its environmental footprint.

Conclusion

In conclusion, moulded fibreglass grating is a superior alternative to traditional materials, offering durability, safety, ease of installation, and low maintenance costs. Its versatility allows it to meet the challenges of various industrial applications and contributes to sustainable practices. As industries continue to seek efficient and cost-effective solutions, the adoption of moulded fibreglass grating is likely to grow, establishing it as a staple in modern construction and facility management.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025