loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Innovative Molded Grating Solutions for Enhanced Performance and Versatility in Various Applications

Understanding Molded Grating and Its Applications

Molded grating is an innovative composite material widely used in various industries for its durability, versatility, and lightweight properties. Primarily composed of fiberglass reinforced plastic (FRP), molded grating is manufactured through a process that involves molding resin and glass fibers into a grid-like structure. This unique manufacturing technique results in a product that possesses several advantageous characteristics, making it ideal for numerous applications.

One of the most significant benefits of molded grating is its corrosion resistance. Traditional materials like steel and wood can suffer from deterioration due to environmental exposure, particularly when they come in contact with harsh chemicals, moisture, or extreme temperatures. Molded grating, on the other hand, is impervious to chemicals and does not rot, rust, or warp. This resilience allows it to be effectively utilized in industries such as chemical processing, wastewater treatment, and marine environments, where corrosion is a major concern.

Another notable aspect of molded grating is its lightweight nature compared to steel or concrete alternatives

. This feature allows for easier installation and handling, which translates into lower labor costs and reduced construction time. The ease of installation is particularly advantageous in areas that require overhead installations, as it minimizes the physical strain on workers and enhances safety on job sites. Moreover, molded grating can be customized in various colors, sizes, and load-bearing capacities, providing flexibility to meet specific project requirements.molded grating

Safety is a paramount concern across many sectors, and molded grating excels in this area as well. Its slip-resistant surface significantly reduces the risk of accidents in high-traffic areas. Whether in industrial plants, commercial kitchens, or public walkways, the anti-slip properties of molded grating contribute considerably to maintaining safety standards. Additionally, its open-grid design allows for excellent drainage, promoting a dry and safe working environment by preventing the accumulation of water.

Molded grating is also an environmentally friendly choice. The materials used in its production can be recycled, and its longevity reduces the need for frequent replacements, leading to lower overall waste. In an era where sustainability is increasingly prioritized, molded grating stands out as a responsible choice for businesses looking to minimize their environmental footprint.

Various industries have begun to recognize the benefits of molded grating, leading to its adoption in many applications. In industrial settings, it is commonly used for walkways, platforms, and stairways. In the food and beverage industry, it serves as flooring in processing plants and commercial kitchens, where hygiene and safety are critical. Additionally, molded grating is employed in construction, water treatment facilities, and even in residential settings, such as pool decking and outdoor patios.

In conclusion, molded grating represents a remarkable advancement in construction materials, offering a combination of strength, safety, and sustainability. Its resistance to corrosion, lightweight design, slip-resistant surface, and environmental benefits make it a preferred choice for a wide variety of applications. As industries continue to evolve and prioritize innovation and safety, molded grating is poised to remain instrumental in shaping future construction practices. Whether in industrial, commercial, or residential applications, molded grating stands as a testament to modern engineering and design, combining functionality with durability for a more efficient and safe environment.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

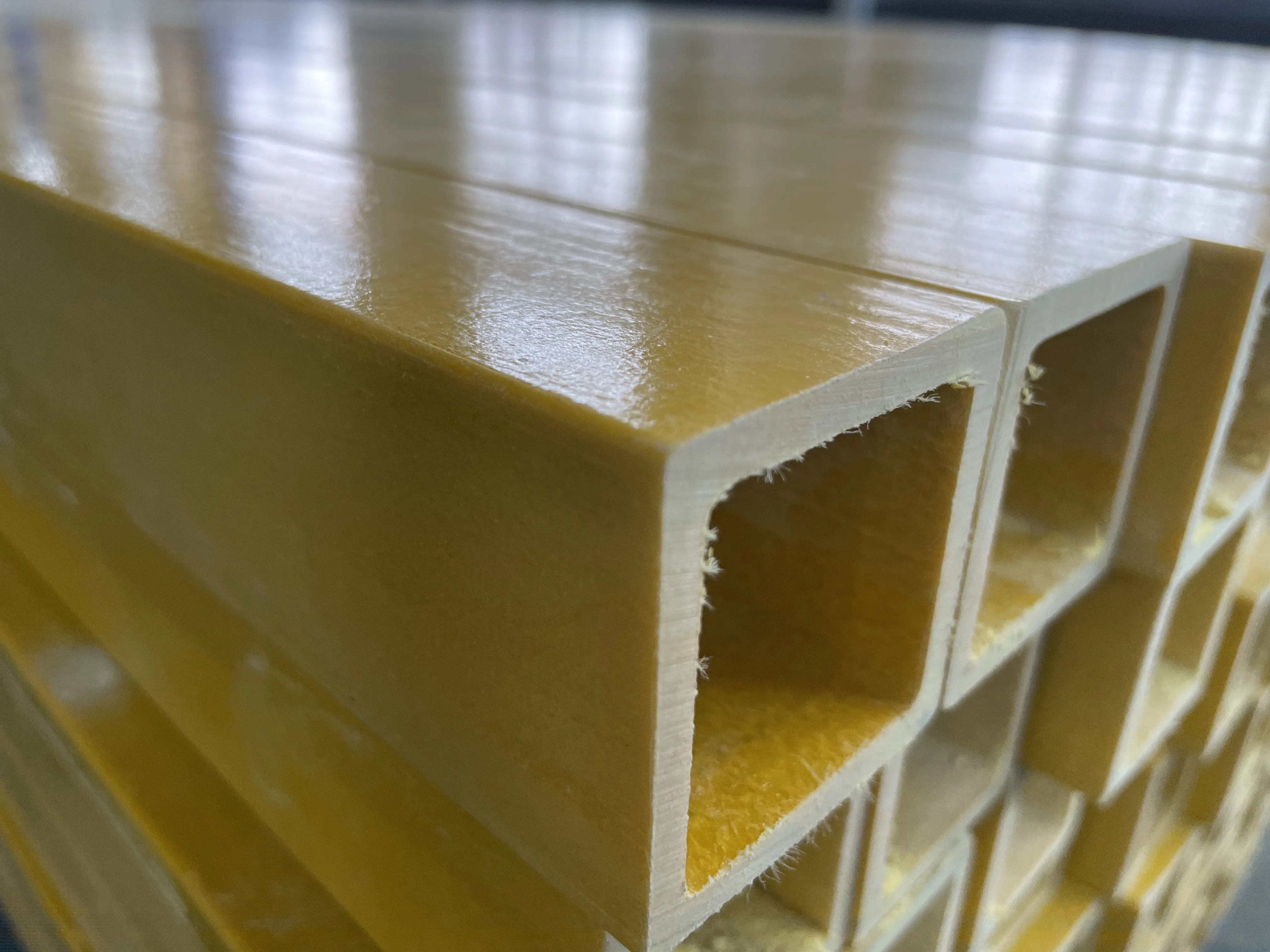

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025