loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

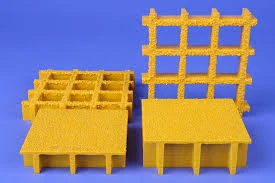

Innovative GRP Floor Grating Solutions for Enhanced Safety and Durability

The Versatility of GRP Floor Grating

Glass Reinforced Plastic (GRP) floor grating has emerged as a popular choice across various industries due to its unique properties and numerous advantages. As technology advances, so too does the need for materials that are not only durable but also versatile, lightweight, and resistant to corrosion. GRP floor grating meets these demands, proving to be a vital component in numerous applications.

What is GRP Floor Grating?

GRP floor grating is composed of a composite material that combines glass fibers with a plastic resin, offering incredible strength and durability. The result is a lightweight yet robust grating solution that can withstand harsh environments. Unlike traditional materials like metal or wood, GRP does not rust, rot, or degrade, making it ideal for areas exposed to moisture or corrosive substances.

Key Advantages

1. Corrosion Resistance One of the primary benefits of GRP floor grating is its resistance to chemical corrosion. This quality makes it particularly valuable in industries such as wastewater treatment, chemical processing, and marine environments where contact with corrosive agents is a daily occurrence.

2. Lightweight and Strong GRP floor grating is significantly lighter than metal grating, making it easier to handle, transport, and install. Despite its lightweight nature, it offers a high load-bearing capacity, ensuring it can support heavy equipment and foot traffic without compromising safety.

3. Safety Features The surface of GRP floor grating can be designed to be slip-resistant, providing an essential safety feature in environments where spills or wet conditions may occur. This makes it suitable for industrial environments, walkways, and platforms.

grp floor grating

4. Low Maintenance Unlike other materials that require regular upkeep, GRP floor grating is incredibly low maintenance. Its non-porous surface resists dirt and stains, often requiring only periodic cleaning to maintain its appearance. This quality can lead to significant cost savings over time.

5. Customizable Options GRP floor grating can be molded into various shapes, sizes, and colors to meet specific project requirements. Whether it's for industrial use, decorative purposes, or specialized environments, there is likely a GRP solution that fits the bill.

Applications of GRP Floor Grating

The versatility of GRP floor grating makes it suitable for a wide range of applications. In industries such as oil and gas, offshore platforms utilize GRP grating to provide safe access points in corrosive environments. In construction, it is used in pedestrian walkways and platforms, ensuring safety while being mindful of structural integrity.

Moreover, the agricultural sector benefits from GRP floor grating in livestock facilities, where durability and hygiene are paramount. The non-absorbent nature of GRP makes it easier to clean, helping maintain the health of animals and the overall cleanliness of facilities.

Conclusion

As industries continue to evolve, so does the demand for effective and efficient materials. GRP floor grating stands out as a solution that combines innovation with practicality. Its unique properties, ranging from corrosion resistance to low maintenance and customizable designs, ensure that it remains a leading choice for many applications. With ongoing advancements in manufacturing and application of GRP, it is likely that its popularity will only continue to grow, providing solutions that cater to the ever-changing needs of various sectors. Choosing GRP floor grating isn't just a decision for today; it's an investment in the future.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025