loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Innovative Designs and Applications of HDG Pressed Steel Tanks for Various Industries and Storage Solutions

Understanding HDG Pressed Steel Tanks Features, Benefits, and Applications

Pressed steel tanks, particularly those that are hot-dip galvanized (HDG), have become increasingly popular in various industrial and agricultural applications. These tanks are not only robust and durable but also offer resistance to corrosion, making them an ideal choice for storing a wide range of liquids.

What is HDG?

Hot-dip galvanizing (HDG) is a process in which steel is immersed in molten zinc, creating a protective layer that prevents rust and corrosion. This method is widely recognized for its effectiveness in prolonging the life of steel products, especially those exposed to harsh environmental conditions. The HDG process ensures that every part of the tank is coated, yielding a uniform layer of protection that is harder to achieve with other methods of galvanization.

Key Features of HDG Pressed Steel Tanks

1. Corrosion Resistance The primary advantage of HDG pressed steel tanks is their remarkable resistance to corrosion. The zinc coating acts as a sacrificial anode, meaning that it will corrode before the steel beneath it. This extends the lifespan of the tank significantly, even in aggressive environments.

2. Strength and Durability Pressed steel tanks are engineered from high-strength steel materials, ensuring they can withstand high pressure and heavy loads. Their structural integrity makes them suitable for a variety of storage needs, from water to chemicals and fuels.

3. Customizable Design These tanks can be produced in various shapes and sizes to meet specific requirements. Whether it’s a vertical tank for limited space or a horizontal tank for easy accessibility, the versatility of design allows for tailored solutions in different applications.

4. Easy Maintenance The smooth finish of HDG tanks not only aids in cleanliness but also reduces the buildup of sludge and other contaminants. Regular inspections and maintenance are simplified, further enhancing the tank's longevity.

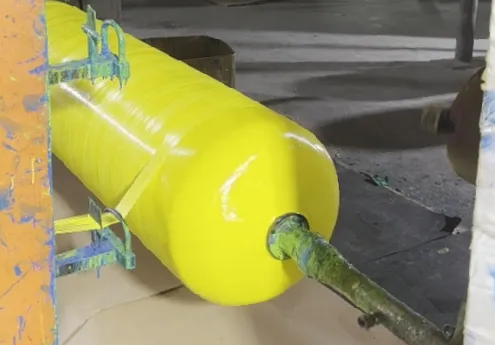

hdg pressed steel tank

5. Eco-Friendly Hot-dip galvanizing is an environmentally friendly process. Zinc is a natural resource, and the tanks can be recycled at the end of their life cycle. Utilizing HDG technology minimizes the environmental impact associated with storage tanks.

Applications of HDG Pressed Steel Tanks

1. Water Storage From municipal water supply systems to agricultural irrigation, HDG pressed steel tanks are widely used for storing potable water. Their resistance to rust ensures that the quality of the water remains uncontaminated.

2. Agricultural Uses Farmers utilize these tanks for rainwater collection, fertilizer storage, and even for livestock feed. The robust design can handle the necessary weights and is durable enough to withstand outdoor conditions.

3. Chemical Storage Industries often require safe storage for chemicals, which may be corrosive or reactive. HDG pressed steel tanks provide the necessary strength and corrosion resistance to safely store such materials.

4. Fuel Storage With the increasing need for efficient fuel storage solutions, these tanks have gained traction in energy sectors. Their design safeguards against leaks, ensuring compliance with safety regulations.

5. Waste Management In the waste management sector, HDG pressed steel tanks are frequently used for storing industrial waste and effluent. Their resistance to various chemicals helps prevent leaks and environmental contamination.

Conclusion

HDG pressed steel tanks present an excellent solution for a wide array of storage needs. With their unmatched corrosion resistance, strength, and versatility in design, they stand out as a reliable choice for industries ranging from agriculture to chemical manufacturing. As the demand for durable and sustainable storage solutions grows, HDG technology continues to evolve, ensuring that these tanks meet modern requirements while minimizing environmental impact. By understanding the advantages and applications of HDG pressed steel tanks, businesses can make informed decisions that enhance operational efficiency and safety.

-

Premium FRP Handrail for All ApplicationsNewsAug.29,2025

-

Low Maintenance FRP Mini Mesh Grating ProductsNewsAug.29,2025

-

Innovative FRP Square Tubes for Modern Industrial SolutionsNewsAug.29,2025

-

FRP Water Storage Tanks Wholesale Solutions for Bulk BuyersNewsAug.29,2025

-

FRP Molded Grating Solutions for Diverse Industrial ApplicationsNewsAug.29,2025

-

Construction Advancements Through FRP Pultruded ProfilesNewsAug.29,2025

-

Why Choose FRP Railings, Guardrails, and Handrail Systems?NewsAug.29,2025