loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Innovative Design of Starlite FRP Vessel for Enhanced Performance and Durability

The Compatibility and Advantages of Starlite FRP Vessels

In recent years, the industrial landscape has witnessed a significant shift towards innovative materials that offer enhanced performance, durability, and environmental sustainability. One such remarkable advancement is the development of Starlite FRP (Fiber Reinforced Polymer) vessels. These vessels are increasingly gaining popularity across various sectors, including chemical processing, water treatment, and food storage, due to their distinct advantages over traditional materials.

Understanding FRP Technology

Fiber Reinforced Polymer (FRP) is a composite material made from a polymer matrix reinforced with fibers, typically glass, carbon, or aramid. The unique combination of these materials results in a lightweight yet robust structure that exhibits remarkable chemical resistance, making it ideal for applications where traditional materials might fail. Starlite FRP vessels harness these properties, providing a reliable solution for the storage and transport of aggressive chemicals and other materials.

Key Benefits of Starlite FRP Vessels

1. Corrosion Resistance One of the most notable advantages of Starlite FRP vessels is their exceptional resistance to corrosion. Unlike metal tanks, which can degrade over time when exposed to various chemicals and environmental conditions, FRP vessels maintain their integrity. This property is particularly critical in industries such as chemical manufacturing and wastewater treatment, where corrosive substances are commonplace.

2. Lightweight and Durable Starlite FRP vessels are significantly lighter than their metal counterparts, making them easier to handle, transport, and install. This lightweight characteristic can lead to reduced operational costs, especially in scenarios requiring frequent relocation or installation in challenging environments. Despite their lightweight nature, these vessels do not compromise on strength, offering long-term durability and reliability.

starlite frp vessel

3. Thermal Insulation FRP vessels provide excellent thermal insulation properties, which are vital in applications requiring temperature control. This insulation helps in maintaining the integrity of the contents, preventing overheating or temperature fluctuations that could compromise product quality.

4. Customizable Designs The versatility of FRP technology allows for the manufacturing of vessels in a variety of shapes, sizes, and configurations. This customization capability means that businesses can tailor their storage solutions to meet specific needs and regulatory requirements without incurring significant costs associated with modification or sourcing specialized equipment.

5. Sustainability As industries globally face increasing pressure to adopt sustainable practices, Starlite FRP vessels emerge as a green alternative. The lifecycle of FRP products tends to be more environmentally friendly, as their production often requires less energy compared to traditional materials. Additionally, many FRP materials are recyclable at the end of their lifespan, reducing waste and environmental impact.

Applications Across Industries

Starlite FRP vessels are versatile and find applications in numerous sectors. In the chemical industry, they are frequently used for the storage of acids, caustics, and other hazardous materials. In the water treatment sector, these vessels facilitate the effective storage of both potable water and wastewater, ensuring compliance with environmental regulations. In the food and beverage industry, Starlite FRP vessels are utilized to store ingredients and products safely, minimizing contamination risks.

Conclusion

In conclusion, Starlite FRP vessels represent a significant advancement in material technology that meets the diverse needs of modern industries. Their corrosion resistance, lightweight durability, excellent thermal insulation, customization options, and sustainability make them an attractive choice for businesses looking to improve their operational efficiency and reduce environmental impact. As technology continues to evolve, it is likely that the adoption of Starlite FRP vessels will become even more widespread, marking a new era in storage solutions.

-

Premium FRP Handrail for All ApplicationsNewsAug.29,2025

-

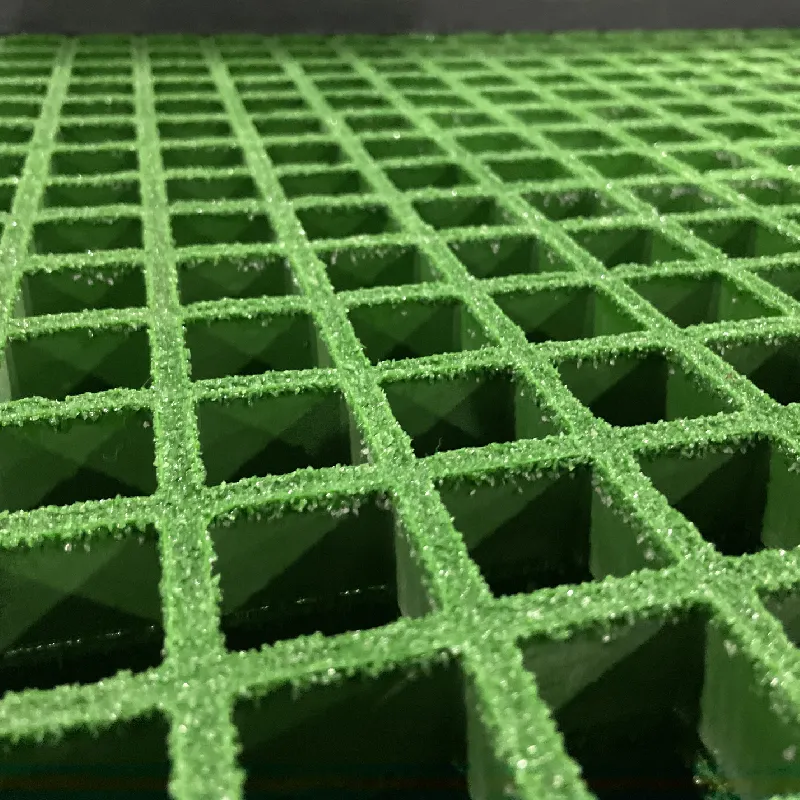

Low Maintenance FRP Mini Mesh Grating ProductsNewsAug.29,2025

-

Innovative FRP Square Tubes for Modern Industrial SolutionsNewsAug.29,2025

-

FRP Water Storage Tanks Wholesale Solutions for Bulk BuyersNewsAug.29,2025

-

FRP Molded Grating Solutions for Diverse Industrial ApplicationsNewsAug.29,2025

-

Construction Advancements Through FRP Pultruded ProfilesNewsAug.29,2025

-

Why Choose FRP Railings, Guardrails, and Handrail Systems?NewsAug.29,2025