loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Innovative Design and Applications of FRP Tanks and Vessels in Modern Industries

Exploring the Benefits of FRP Tanks and Vessels

Fiberglass Reinforced Plastic (FRP) tanks and vessels have gained widespread popularity in various industries due to their unique properties and advantages over traditional materials. These composite structures, composed of a polymer matrix reinforced with fibrous materials, offer an array of benefits that make them ideal for numerous applications, including water and wastewater treatment, chemical storage, and even oil and gas industries.

One of the primary advantages of FRP tanks and vessels is their exceptional resistance to corrosion. Unlike metal tanks that can rust and corrode when exposed to harsh chemicals or moisture, FRP structures maintain their integrity over time. This resilience is particularly crucial in industries dealing with aggressive chemicals, as it minimizes the risk of leaks and contamination. Consequently, facilities can operate more safely and without the frequent need for maintenance associated with metal options.

Exploring the Benefits of FRP Tanks and Vessels

Moreover, FRP vessels offer excellent insulation properties. This feature is particularly beneficial for processes that require temperature control, as it helps maintain the desired temperature while minimizing energy costs. For example, in the chemical industry, maintaining the temperature of corrosive or reactive substances is critical to ensure safe and efficient processes. Insulated FRP tanks can help achieve stable thermal conditions, thereby enhancing overall operational efficiency.

frp tank and vessel

Another notable benefit of FRP tanks and vessels is their durability. These structures can withstand extreme weather conditions, including UV radiation, high temperatures, and heavy winds. This durability extends their service life, providing a reliable storage solution that requires minimal replacement and repair. As industries look for sustainable options in their operations, the long lifespan of FRP materials aligns perfectly with the goals of reducing overall waste and promoting environmental sustainability.

Additionally, safety is a paramount consideration in industrial applications, and FRP tanks contribute positively in this aspect. Their non-conductive nature minimizes the risk of electrical hazards, and their ability to contain leaks safely protects both the environment and personnel. In the event of a rupture, the nature of the material reduces the risk of hazardous spills, ensuring compliance with environmental regulations and enhancing workplace safety.

Lastly, the ability to customize FRP tanks and vessels adds to their appeal. Manufacturers can create bespoke solutions to meet the specific requirements of clients, from size and shape to color and finish. This flexibility enables industries to integrate storage solutions seamlessly into existing systems or new constructions.

In conclusion, FRP tanks and vessels are becoming the go-to choice for numerous industries due to their outstanding corrosion resistance, lightweight properties, insulation capability, durability, safety, and customization options. As industries continue to prioritize efficiency, safety, and sustainability, FRP solutions stand out as a modern alternative that meets the evolving demands of today's challenges. Whether it is for storing wastewater, chemicals, or other critical materials, FRP will undoubtedly play a vital role in shaping the future of industrial storage solutions.

-

Premium FRP Handrail for All ApplicationsNewsAug.29,2025

-

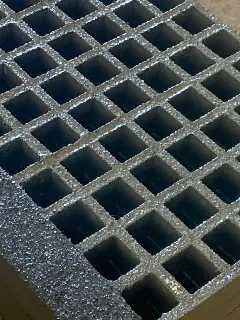

Low Maintenance FRP Mini Mesh Grating ProductsNewsAug.29,2025

-

Innovative FRP Square Tubes for Modern Industrial SolutionsNewsAug.29,2025

-

FRP Water Storage Tanks Wholesale Solutions for Bulk BuyersNewsAug.29,2025

-

FRP Molded Grating Solutions for Diverse Industrial ApplicationsNewsAug.29,2025

-

Construction Advancements Through FRP Pultruded ProfilesNewsAug.29,2025

-

Why Choose FRP Railings, Guardrails, and Handrail Systems?NewsAug.29,2025