loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Innovative Design and Applications of FRP Structural Components in Modern Engineering

FRP Structural Members A Revolutionary Approach in Modern Construction

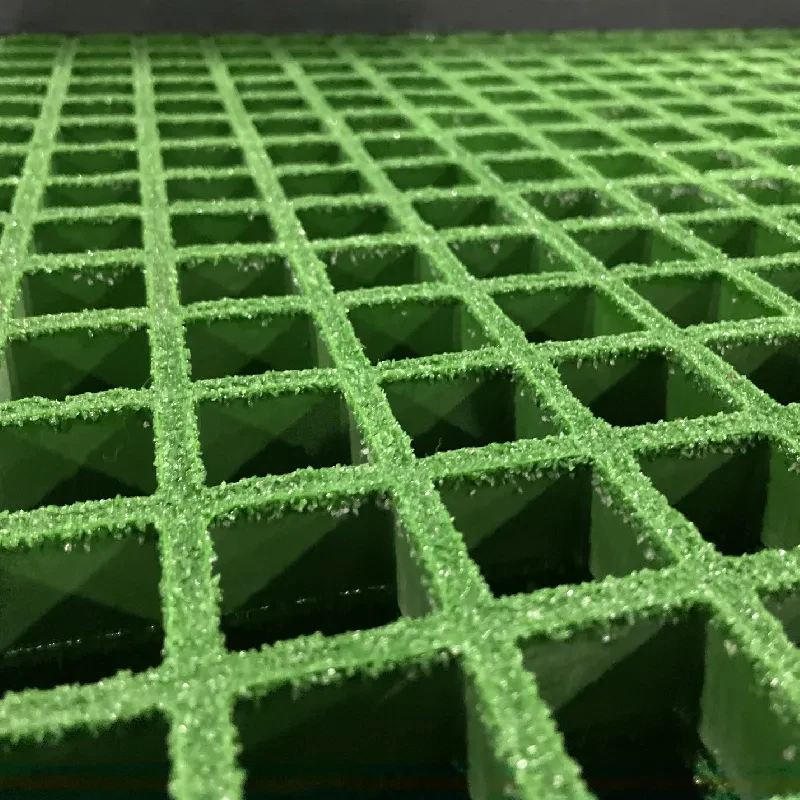

Fiber Reinforced Polymer (FRP) has emerged as a transformative material for structural members in modern construction, offering distinct advantages that traditional materials like steel and concrete cannot match. This high-performance composite material consists of a polymer matrix reinforced with fibers, typically glass, carbon, or aramid. FRP's unique combination of lightweight properties, high strength, and resistance to corrosion makes it an ideal choice for a variety of engineering applications.

One of the most significant benefits of FRP structural members is their lightweight nature. Compared to steel and concrete, FRP is significantly lighter, making it easier to handle and transport. This reduction in weight can lead to lower construction costs, especially in projects where heavy lifting equipment would be required to move traditional materials. Additionally, since FRP components are easier and quicker to install, they contribute to shorter construction timelines, allowing projects to be completed more efficiently.

FRP Structural Members A Revolutionary Approach in Modern Construction

Corrosion resistance is another critical advantage of FRP structural members. Traditional materials, particularly steel, face significant challenges in harsh environments, like coastal areas or chemical plants, where exposure to moisture and corrosive substances can lead to premature failure. FRP, on the other hand, is intrinsically resistant to corrosion, resulting in lower maintenance costs and longer lifespan. This durability is particularly valuable in infrastructure applications, where the lifecycle cost is a major consideration.

frp structural members

Another compelling attribute of FRP is its design flexibility. The manufacturing process allows for the creation of complex shapes and sizes tailored to specific engineering needs. Designers can leverage this property to create intricate geometries that would be challenging or impossible to achieve with conventional materials. Moreover, FRP can be molded into various forms, allowing for innovative architectural designs that enhance both functionality and aesthetics.

While the benefits of FRP structural members are clear, it is important to acknowledge the challenges associated with their use. The initial cost of FRP can be higher than traditional materials, primarily due to the manufacturing processes and raw materials involved. However, when considering the total lifecycle costs—including maintenance, durability, and installation savings—FRP often proves to be a more cost-effective solution in the long run.

Moreover, as the technology and production processes continue to evolve, the price of FRP materials is expected to decrease, making them more accessible for a broader range of applications. Furthermore, ongoing research and development aim to improve their mechanical properties and sustainability, addressing environmental concerns associated with the production of synthetic materials.

In conclusion, FRP structural members represent a significant innovation in the field of construction and civil engineering. Their lightweight nature, remarkable strength, corrosion resistance, and design flexibility make them an attractive option for modern infrastructure projects. As technology advances and the construction industry increasingly embraces sustainable practices, the use of FRP is likely to grow, paving the way for a new era of resilient and durable structures. With the potential to transform the way we build, FRP stands out as a remarkable material that can meet the demands of 21st-century construction challenges.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025