loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Innovative Applications of Structural FRP in Modern Engineering and Construction Techniques

Understanding Structural FRP A Comprehensive Overview

Structural Fiber Reinforced Polymer (FRP) has emerged as a crucial material in the field of civil engineering and construction. Its unique properties and benefits make it an appealing choice for various structural applications, challenging traditional materials like steel and concrete. This article delves into the characteristics, advantages, and applications of structural FRP, highlighting its transformative role in modern engineering.

What is Structural FRP?

Fiber Reinforced Polymer (FRP) is a composite material that consists of a polymer resin bonded with various fibers, typically glass, carbon, or aramid. These fibers provide superior strength-to-weight ratios compared to traditional materials, while the polymer matrix offers resistance to corrosion, moisture, and chemicals. The combination results in a lightweight yet robust structural material that can be tailored to meet specific engineering requirements.

Key Properties of Structural FRP

1. High Strength-to-Weight Ratio One of the most significant advantages of FRP is its high strength-to-weight ratio. This property allows for lighter structures, which can lead to cost savings in foundation requirements and transportation.

2. Corrosion Resistance Unlike steel, FRP does not corrode when exposed to harsh environmental conditions. This makes it particularly suitable for structures in aggressive environments, such as coastal areas and chemical plants.

3. Thermal Stability FRP maintains its structural integrity over a wide range of temperatures, making it suitable for both hot and cold climates. Its thermal insulation properties also contribute to energy efficiency in buildings.

4. Versatility and Design Flexibility The manufacturing process of FRP allows for intricate shapes and designs, offering engineers and architects greater flexibility in creative and functional applications.

5. Ease of Installation The lightweight nature of FRP facilitates easier handling and installation, reducing labor costs and construction time.

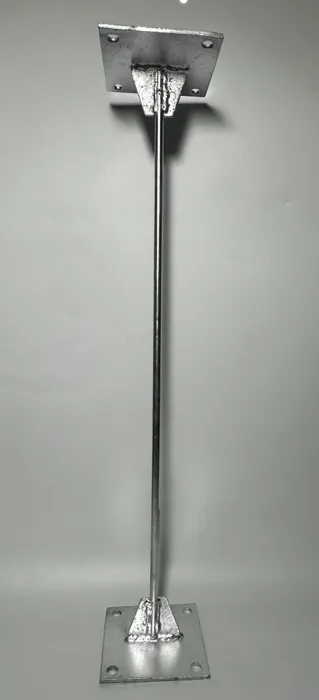

structural frp

Applications of Structural FRP

The applications of structural FRP are expanding across various sectors, addressing the specific needs of modern infrastructure and construction. Some of the notable applications include

1. Bridge Construction FRP is increasingly used in bridge design due to its strength, lightweight properties, and resistance to corrosion. It allows for longer spans and reduced maintenance needs compared to traditional materials.

2. Building Structures In high-rise buildings and industrial structures, FRP can be used as an alternative to steel reinforcements, providing a lighter load while maintaining high strength.

3. Retrofitting and Rehabilitation FRP is often employed in strengthening existing structures. Its application in retrofitting allows for the enhancement of load capacity and the prolongation of a structure's life.

4. Marine and Offshore Applications The ability of FRP to resist seawater and chemicals makes it a valuable choice for marine construction, including docks, piers, and offshore platforms.

5. Transportation Infrastructure FRP is employed in the construction of railways, tunnels, and airports, where durability and weight are paramount for safety and efficiency.

Conclusion

Structural FRP represents a significant advancement in material science, offering a combination of properties that address the challenges faced by traditional construction materials. Its applications across various sectors underscore the importance of adopting innovative solutions in engineering. As technology continues to evolve, structural FRP is expected to play an integral role in the future of construction, paving the way for sustainable and resilient infrastructure.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025