loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Innovative Applications of FRP Rectangular Tubes in Structural Engineering and Design

Understanding FRP Rectangular Tubes Applications and Benefits

Fiber Reinforced Polymer (FRP) rectangular tubes have emerged as a significant innovation in the field of material science and engineering. These composite materials, known for their strength, lightweight nature, and durability, have gained wide acceptance across various industries, including construction, automotive, aerospace, and marine applications. This article explores the characteristics, advantages, and applications of FRP rectangular tubes.

What Are FRP Rectangular Tubes?

FRP rectangular tubes are composite materials formed by embedding fibers, typically glass, carbon, or aramid, within a polymer matrix. The fibers provide excellent tensile strength and stiffness, while the polymer matrix offers protection against environmental factors and contributes to the overall structural integrity of the composite. The rectangular shape of these tubes allows for efficient handling and versatile applications in various mechanical and structural systems.

Key Advantages of FRP Rectangular Tubes

1. High Strength-to-Weight Ratio One of the most compelling advantages of FRP rectangular tubes is their high strength-to-weight ratio. They possess superior strength compared to traditional materials such as steel and aluminum while being significantly lighter. This characteristic is particularly beneficial in applications where weight reduction is critical, such as in the aerospace and automotive sectors.

2. Corrosion Resistance FRP materials are inherently resistant to chemical and environmental degradation. Unlike metals that corrode over time, FRP rectangular tubes can withstand harsh environments, including exposure to moisture, salts, and various chemicals. This property extends their lifespan, reducing maintenance costs and enhancing safety.

3. Flexibility in Design FRP rectangular tubes can be manufactured in various shapes, sizes, and configurations, offering engineers and architects great flexibility in design. They can be tailored to meet specific load requirements and aesthetic preferences, making them suitable for innovative architectural designs and intricate structural applications.

4. Thermal and Electrical Insulation Unlike metals, FRP materials offer excellent thermal and electrical insulation properties. This makes FRP rectangular tubes ideal for applications where thermal management and electrical conductivity need to be minimized, such as in electrical enclosures and components that require thermal protection.

frp rectangular tube

5. Sustainability The production of FRP materials can be more environmentally friendly compared to traditional materials. Many fiber sources are renewable, and advancements in recycling technologies are making it possible to repurpose used FRP products, further reducing the environmental footprint.

Applications of FRP Rectangular Tubes

FRP rectangular tubes have found a wide array of applications across different sectors

- Construction In modern construction, FRP rectangular tubes are utilized in structural supports, railings, and bridges due to their strength, lightweight nature, and resistance to corrosion.

- Automotive Industry These tubes are used in vehicle frames, chassis components, and protective structures to enhance fuel efficiency and performance while ensuring safety.

- Aerospace Applications The aerospace industry benefits significantly from FRP materials due to their lightweight properties, which allow for improvements in fuel efficiency and overall performance of aircraft.

- Marine Applications Here, FRP rectangular tubes are used in boat construction and infrastructure due to their water resistance and minimal maintenance requirements.

Conclusion

FRP rectangular tubes represent a remarkable advancement in composite material technology, combining strength, lightweight properties, and resistance to environmental degradation. Their versatility across various industries highlights their potential as a replacement for traditional materials like steel and aluminum. As technology continues to evolve, the applications and benefits of FRP rectangular tubes are likely to expand, paving the way for innovative solutions in engineering and design. This composite material is indeed a testament to the integration of modern science and engineering in creating sustainable and efficient products for the future.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

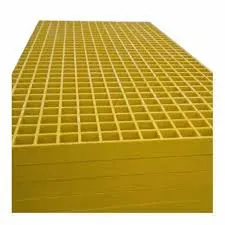

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025