loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Innovative Applications of Fiber Reinforced Polymer Bars in Enhancing Concrete Structure Durability and Strength

Fiber Reinforced Polymer Bars in Concrete A Modern Solution for Structural Integrity

In recent years, the construction industry has witnessed a significant transformation with the introduction of advanced materials aimed at enhancing structural integrity and longevity. Among these innovations, Fiber Reinforced Polymer (FRP) bars have emerged as a leading alternative to traditional steel reinforcement in concrete structures. This article explores the characteristics, benefits, and challenges associated with the use of FRP bars in concrete applications.

What are FRP Bars?

FRP bars are composed of a polymer matrix reinforced with fibers, commonly glass, carbon, or aramid. They are lightweight, non-corrosive, and have high tensile strength, making them ideal for reinforcing concrete in various applications. The manufacturing process of FRP bars involves combining the polymer resin with fibers to form a composite material that retains the flexibility of the polymer while gaining strength from the fibers. This unique combination produces a material that is not only strong but also resistant to environmental degradation.

Advantages of Using FRP Bars

1. Corrosion Resistance One of the most significant advantages of FRP bars is their resistance to corrosion. Unlike traditional steel reinforcement, which can deteriorate over time due to exposure to moisture and chemicals, FRP bars maintain their integrity in harsh environments, such as those found in coastal areas or industrial sites. This characteristic significantly extends the lifespan of concrete structures, reducing maintenance costs and enhancing safety.

2. Lightweight The lightweight nature of FRP bars makes them easier to handle and install, resulting in reduced labor costs and improved efficiency on construction sites. Their lower weight also allows for lighter structural designs, which can lead to savings in materials and foundation requirements.

3. High Strength-to-Weight Ratio FRP bars possess a high strength-to-weight ratio, making them suitable for applications requiring significant tensile strength without adding excessive dead weight to the structure. This property is especially beneficial in seismic-prone areas, where reducing weight without compromising structural integrity is critical.

frp bars in concrete

4. Electrical and Thermal Insulation FRP bars are non-conductive, which makes them ideal for applications where electrical insulation is necessary. Additionally, they have low thermal conductivity, which can help maintain temperature stability in certain construction scenarios.

Challenges and Considerations

Despite their numerous advantages, the use of FRP bars also poses certain challenges that must be addressed

1. Higher Initial Costs FRP bars are typically more expensive than traditional steel reinforcement. Although they offer long-term savings through reduced maintenance and replacement costs, the initial investment can be a deterrent for some projects.

2. Design Standards and Codes The adoption of FRP bars in construction requires adjustments to design codes and standards. Engineers and designers must be familiar with the specific properties and behavior of FRP materials to ensure safe and effective use in structural applications.

3. Limited Ductility Unlike steel, which can deform under stress before failure, FRP bars are brittle and do not exhibit significant ductility. This behavior can pose risks in certain structural applications where deformation is a necessary warning sign prior to failure.

Conclusion

Fiber Reinforced Polymer bars represent a significant advancement in concrete reinforcement technology, offering numerous benefits such as corrosion resistance, lightweight properties, and high strength. While challenges remain, particularly in terms of cost and regulatory adoption, the long-term advantages of using FRP in concrete structures are becoming increasingly recognized. As the construction industry continues to evolve, FRP bars may well become a standard component in the design and reinforcement of modern concrete infrastructures, paving the way for safer, more durable, and efficient structures.

-

Premium FRP Handrail for All ApplicationsNewsAug.29,2025

-

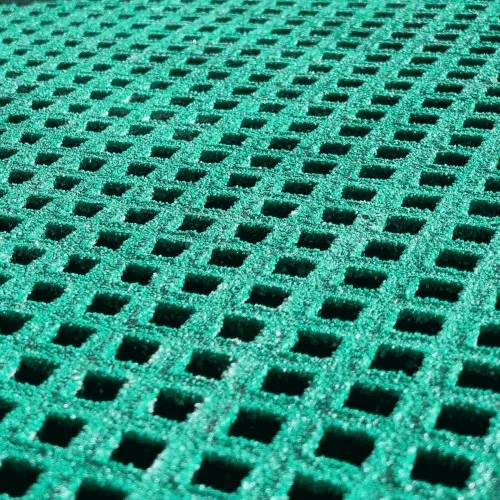

Low Maintenance FRP Mini Mesh Grating ProductsNewsAug.29,2025

-

Innovative FRP Square Tubes for Modern Industrial SolutionsNewsAug.29,2025

-

FRP Water Storage Tanks Wholesale Solutions for Bulk BuyersNewsAug.29,2025

-

FRP Molded Grating Solutions for Diverse Industrial ApplicationsNewsAug.29,2025

-

Construction Advancements Through FRP Pultruded ProfilesNewsAug.29,2025

-

Why Choose FRP Railings, Guardrails, and Handrail Systems?NewsAug.29,2025