loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

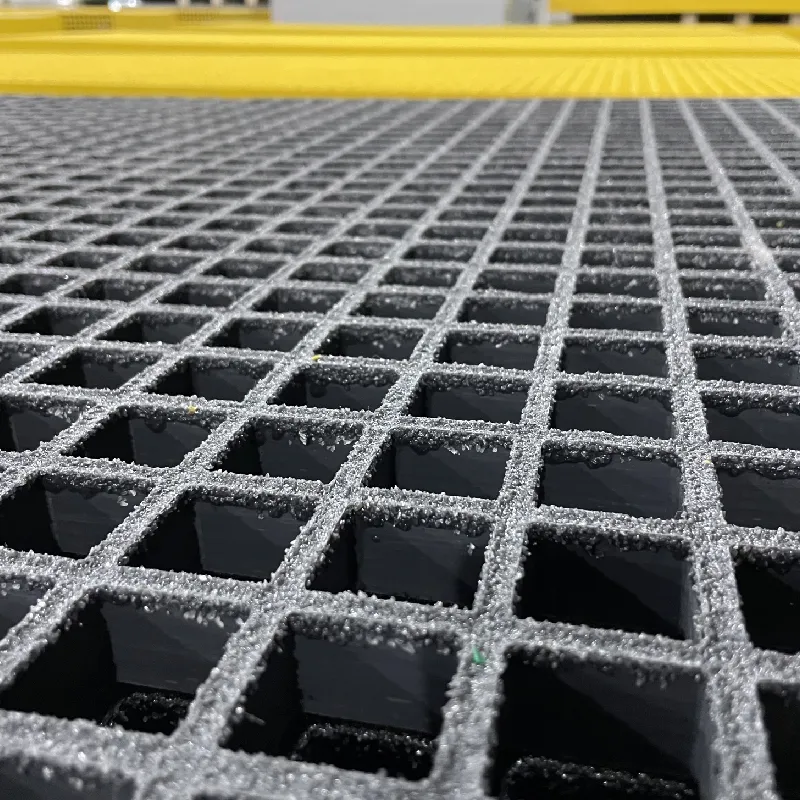

Innovative Applications and Benefits of Fiberglass Grating in Modern Construction and Industrial Settings

Understanding Fiberglass Grating An Overview

Fiberglass grating, commonly referred to as FRP (Fiberglass Reinforced Plastic) grating, is a composite material widely recognized for its strength, durability, and versatility across various industries. Made from a combination of glass fibers and resin, fiberglass grating offers numerous advantages over traditional materials such as steel or wood, making it a preferred choice in numerous applications.

Composition and Manufacturing Process

The primary components of fiberglass grating include a polymer resin matrix and glass reinforcement. The manufacturing process involves the combination of these materials, where the glass fibers are set within a resin matrix and cured to form a solid, lightweight structure. This process can be conducted in different configurations, including molded and pultruded types, each offering distinct characteristics suitable for various applications.

Molded fiberglass grating is created through a process that involves pressing the resin and glass fibers into a mold. This form of grating typically exhibits more intricate designs and patterns, providing additional aesthetic options. Conversely, pultruded grating is produced by pulling the composite materials through a heated die, resulting in uniform profiles with superior strength. This method is ideal for applications requiring high load-bearing capabilities.

Advantages of Fiberglass Grating

One of the standout features of fiberglass grating is its high resistance to corrosion. Unlike traditional metal gratings that can rust and degrade over time, fiberglass grating maintains its structural integrity even in harsh environmental conditions, making it an ideal choice for chemical plants, waste treatment facilities, and marine environments.

Another significant advantage is its lightweight nature. Compared to steel or aluminum, fiberglass grating is considerably lighter, which translates to easier handling and installation. This property not only reduces labor costs but also minimizes the need for heavy equipment during installation, allowing for job site flexibility.

fiberglass grating

Safety is also a key consideration when selecting grating materials. Fiberglass grating is designed to provide excellent slip resistance, particularly when incorporated with textured surfaces. This feature is crucial in environments where spills or wet conditions can cause hazardous situations, such as in food processing plants or industrial settings.

Additionally, fiberglass grating is non-conductive, making it an ideal choice for applications involving electrical hazards. This non-conductivity ensures that installations in electrical substations or areas with high-voltage equipment are safer for workers and enhance overall site safety.

Applications of Fiberglass Grating

The versatility of fiberglass grating has led to its adoption across a broad range of industries. In industrial environments, it is commonly used for walkways, platforms, and stairs, where its strength and corrosion resistance minimize maintenance needs. In maritime applications, it's a favored choice for docks and piers due to its enduring performance in saltwater conditions.

In the construction sector, fiberglass grating finds utility in architectural designs, where it can be used for sunshades, fencing, and decorative features, adding a modern aesthetic to buildings while still being functional. Furthermore, due to its lightweight and strong properties, it is increasingly used in the manufacturing of automotive parts and aerospace components.

Conclusion

In conclusion, fiberglass grating stands out as a robust solution for a myriad of applications across diverse industries. Its combination of strength, lightweight attributes, corrosion resistance, and safety features makes it an invaluable material in both industrial and commercial applications. As technology advances and the demand for innovative materials increases, fiberglass grating will likely continue to play a pivotal role in the future of infrastructure and design. Whether for practical functionality or aesthetic enhancement, fiberglass grating undoubtedly offers a myriad of benefits that cater to the needs of modern industries.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025