loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

industrial water filter system

Industrial Water Filter Systems Ensuring Clean Water for Industrial Applications

As industries grow and evolve, the demand for clean and safe water sources has never been more critical. Industrial water filter systems play a crucial role in maintaining the quality of water used in various industrial processes. With the increasing awareness of environmental issues and the need for sustainable practices, these filtration systems have become essential for numerous sectors, including manufacturing, power generation, and food processing.

Importance of Water Filtration in Industries

Water is a vital resource in any industrial setting. It is used for cooling, processing, cleaning, and even as a raw material in some cases. However, water sources often contain impurities that can affect the quality of the end products, lead to equipment damage, and pose health hazards. Pollutants may include suspended solids, dissolved minerals, chemicals, and biological contaminants. Therefore, having an effective water filtration system is critical to ensuring the safety and quality of industrial operations.

Types of Industrial Water Filter Systems

Industrial water filter systems come in various types, designed to cater to specific filtering needs

1. Activated Carbon Filters These filters utilize activated carbon to remove impurities and contaminants from water, particularly organic compounds and chlorine. They are widely used in food and beverage industries to enhance the taste and odor of water.

2. Reverse Osmosis (RO) Systems RO systems use a semi-permeable membrane to remove ions, molecules, and larger particles from water. This technology is effective in producing high-purity water and is extensively used in pharmaceuticals and electronics manufacturing.

3. Media Filters These filters utilize sand, gravel, or other media to remove suspended solids from water. They are often employed in applications where turbidity control is essential.

4. Ultraviolet (UV) Disinfection Systems UV systems utilize light to kill bacteria and viruses in water. This method is increasingly popular due to its effectiveness and the absence of harmful chemicals in the disinfection process.

5. Ion Exchange Systems These systems are designed to remove specific ions from water, such as calcium and magnesium, which contribute to water hardness. They are commonly used in boiler feed water treatment to prevent scaling and corrosion in equipment.

Benefits of Implementing Industrial Water Filter Systems

Implementing a robust water filtration system offers numerous benefits to industrial operations

industrial water filter system

- Improved Product Quality Clear and clean water enhances the quality of final products, leading to better customer satisfaction and reduced returns.

- Equipment Longevity By removing contaminants that can cause wear and tear, filtration systems help extend the lifespan of machinery and equipment, leading to lower maintenance costs and increased productivity

.- Regulatory Compliance Many industries are required to adhere to strict regulations concerning water quality. Implementing effective filtration systems helps companies meet these requirements and avoid potential fines and legal issues.

- Environmental Benefits Effective water filtration promotes sustainability by reducing the amount of polluted water discharged into the environment. It enables companies to reuse and recycle water, thereby conserving this precious resource.

Challenges in Implementing Water Filter Systems

Despite the clear benefits, there are challenges that industries may face when implementing water filtration systems

- Initial Costs The upfront investment for purchasing and installing efficient filtration systems can be substantial. However, these costs can be justified by long-term savings.

- Maintenance Continuous operation requires regular maintenance and monitoring. Neglecting maintenance might lead to system inefficiencies and increased operational costs.

- Waste Management The filtration process often results in waste, such as spent filter media or backwash. Industries must have a comprehensive waste management strategy in place to address these byproducts.

The Future of Industrial Water Filtration

As technology advances, the future of industrial water filtration systems looks promising. Emerging innovations, such as smart sensors and IoT integration, will enable real-time monitoring and optimization of filtration processes. Furthermore, the growing trend towards sustainability and water reuse will likely drive further enhancements in filtration technologies.

In conclusion, industrial water filter systems are indispensable for ensuring clean water in industrial processes. By investing in appropriate filtration technologies, industries can enhance product quality, protect equipment, comply with regulations, and promote environmental sustainability. As the industrial landscape continues to evolve, so too will the methods we employ to manage and conserve one of our most vital resources—water.

-

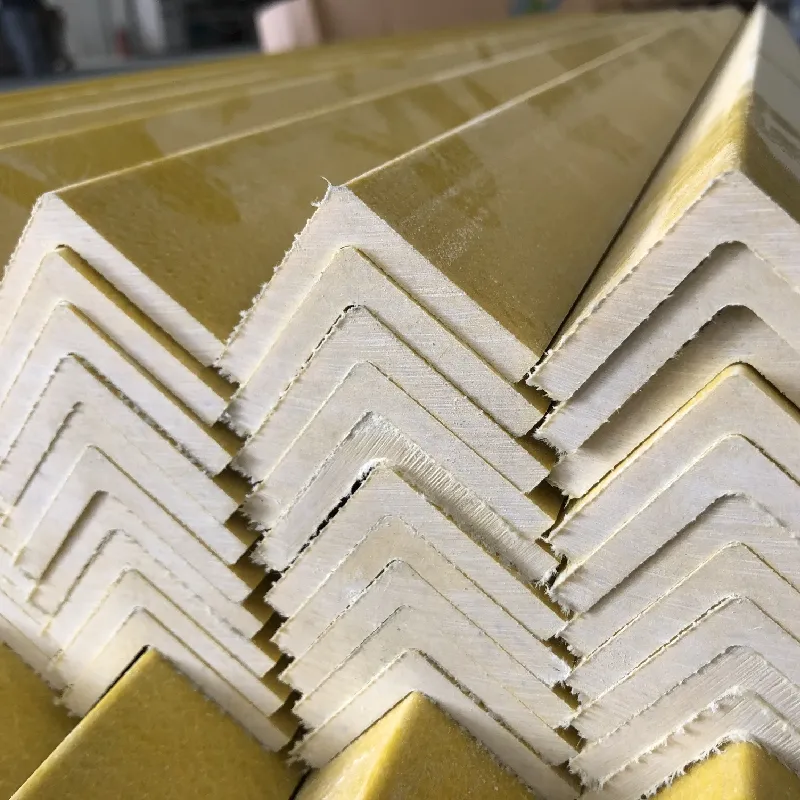

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025