loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Industrial Water Filtration Solutions for Enhanced Efficiency and Purity

The Importance of Industrial Water Filters

Water is a critical resource in industrial processes, serving not only as a medium for chemical reactions but also as a coolant, solvent, and transporter of materials. Given its essential role, the quality of water used in industrial applications is paramount. Contaminated water can lead to inefficiencies, damages to equipment, and could even pose health risks to workers. This is where industrial water filters come into play, ensuring that water meets the required standards for various industrial uses.

Understanding Industrial Water Filters

Industrial water filters are systems designed to remove impurities from water used in industrial processes. These impurities can include suspended solids, bacteria, algae, and chemical contaminants. The filtration systems may consist of various technologies, including sand filters, activated carbon filters, membrane systems, and reverse osmosis units, tailored to meet the specific needs of an industry or process.

The choice of an appropriate filtration system depends on several factors, including the source of the water, the type of contaminants present, the required water quality, and the specific industrial process for which the water is needed. For instance, a manufacturing plant may require ultra-pure water for its processes, while a cooling system in a power generation facility may need to filter out larger particulates to prevent clogging and overheating.

Benefits of Using Industrial Water Filters

1. Enhanced Product Quality Impurities in water can lead to inconsistent product quality. By using filters, industries can ensure that the water used in the production process meets high purity standards, leading to better end products.

2. Operational Efficiency Contaminated water can lead to sediment buildup, corrosion, and the failure of equipment. By filtering water, businesses can extend the lifespan of their machinery and reduce maintenance costs.

3. Compliance with Regulations Many industries are subject to strict environmental regulations regarding water usage and discharge. Implementing effective filtration systems helps companies comply with these regulations, avoiding potential fines and legal issues.

4. Environmental Protection Proper filtration can also reduce the environmental footprint of industrial operations. By filtering contaminants before water is discharged back into the environment, companies minimize their impact on local ecosystems.

industrial water filter

5. Cost Savings Although there is an initial investment in water filtration systems, the long-term savings due to reduced equipment failure, maintenance costs, and improved efficiency can outweigh these initial costs. Moreover, industries can often reclaim and recycle water, further reducing operational costs.

Advances in Filtration Technology

The development of filtration technology has come a long way in recent years. Innovations such as nanofiltration and advanced membrane technologies allow for the removal of even smaller contaminants that traditional systems may miss. These advancements enable industries to achieve higher levels of water purity.

Additionally, smart filtration systems equipped with sensors can monitor water quality in real-time, adjusting filtration processes dynamically to ensure optimal performance. This not only improves efficiency but also reduces waste and energy consumption.

Challenges to Implementation

While industrial water filters offer numerous benefits, the implementation of these systems is not without challenges. The initial capital investment can be substantial, and companies must also consider the ongoing maintenance and operation costs. Furthermore, the complexity of some filtration systems may require specialized staff for operation and management.

Another concern is the disposal of waste generated from various filtration processes. Some systems may produce sludge or contaminated materials that require safe and compliant disposal methods.

Conclusion

In conclusion, industrial water filters play a crucial role in ensuring the quality of water used in various industrial applications. By removing contaminants, these systems enhance product quality, improve operational efficiency, and help industries comply with environmental regulations. With ongoing advancements in filtration technology, industries can look forward to even more efficient and effective solutions for their water treatment needs. While challenges remain, the benefits of investing in industrial water filtration systems are clear, making them an essential component of sustainable industrial practices. As we continue to push for better environmental stewardship and resource management, the importance of clean water in industrial settings cannot be overstated.

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025

-

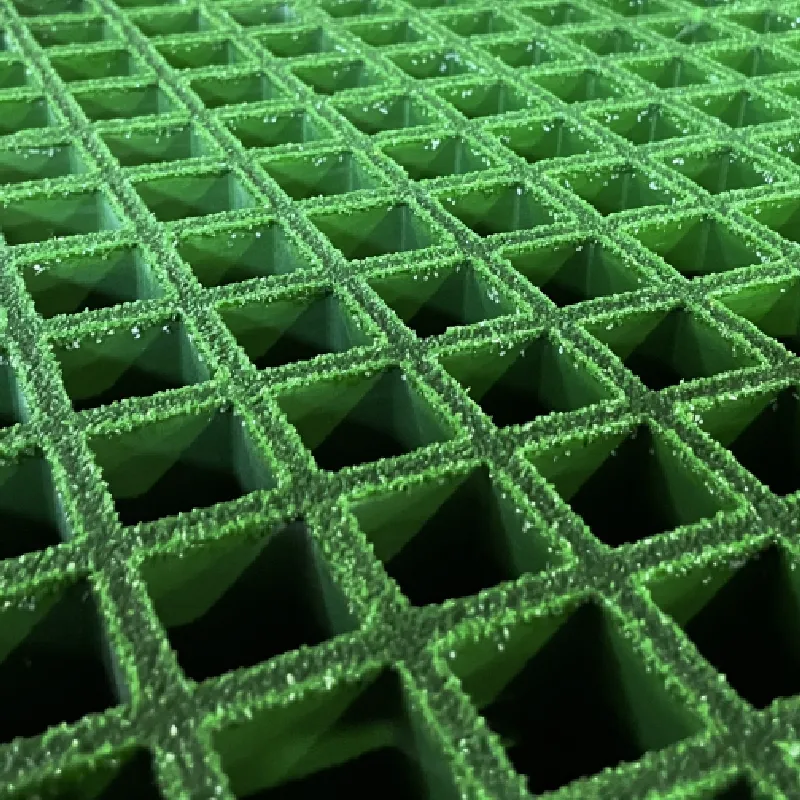

The Strength and Durability of FRP GratingNewsMay.21,2025

-

The Importance of Water Treatment Systems for Clean and Safe WaterNewsMay.21,2025

-

The Advantages of FRP Rebar for Construction ProjectsNewsMay.21,2025

-

Say Goodbye to Hard Water with a Reliable Water SoftenerNewsMay.21,2025

-

Maximize Your Water Storage with a Sectional Water TankNewsMay.21,2025

-

The Power of Filter VesselsNewsMay.19,2025