loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

industrial ro water system

Understanding Industrial RO Water Systems

Reverse Osmosis (RO) technology has become increasingly important in various industries for water purification and treatment. An industrial RO water system is designed to remove contaminants from water through a semi-permeable membrane, providing a reliable and efficient way to ensure water quality. This article will delve into the importance, process, components, and applications of industrial RO water systems.

Importance of Industrial RO Water Systems

In many industries, the availability of high-quality water is crucial for production processes, equipment operation, and compliance with regulatory standards. Industrial RO water systems help to produce distilled, purified, or deionized water, which is essential in sectors such as pharmaceuticals, food and beverage, electronics, and power generation. These systems not only enhance product quality but also contribute to cost savings by reducing downtime caused by equipment damage from impurities in water.

The RO Process Explained

The Reverse Osmosis process involves forcing water through a semi-permeable membrane under pressure. This membrane allows only water molecules to pass through while blocking larger molecules, salts, and contaminants. The process can be broken down into several stages

1. Pre-treatment This initial step often includes filtering the water to remove larger particles, sediment, and chlorine, which can damage the RO membrane. Common pre-treatment methods include multimedia filters, activated carbon filters, and chemical dosing.

2. Pressurization The pre-treated water is then pumped into the RO system under high pressure. This pressure must be sufficient to overcome the osmotic pressure of the water, allowing the pure water to permeate through the membrane.

3. Membrane Filtration As water flows through the RO membrane, contaminants—including dissolved salts, bacteria, and organic molecules—are rejected, leaving behind concentrated waste on one side of the membrane.

4. Post-treatment The purified water often undergoes additional treatment processes, such as UV sterilization or remineralization, to ensure that it meets specific quality standards before being distributed for use.

industrial ro water system

Key Components of Industrial RO Systems

Industrial RO systems typically consist of several components, each playing a vital role in the water purification process

- Pre-filtration Units These remove larger particulates and chlorine, protecting the RO membrane. - RO Membrane Modules Responsible for the separation process, these modules are made of polyamide or cellulose acetate materials. - High-Pressure Pumps These pumps generate the necessary pressure to force water through the membrane. - Pressure Vessels These housings contain the RO membrane modules and withstand high pressure during operation. - Flow Meters and Controls These monitor and control the flow rates of feed water, permeate, and concentrate.

- Post-treatment Equipment Depending on the application, additional treatment stages can include UV lights, carbon filters, and mineral addition systems.

Applications of Industrial RO Water Systems

The versatility of industrial RO systems enables their use in various applications

- Pharmaceuticals Ensures the purity of water used in drug formulation and cleaning processes. - Power Generation Provides high-quality water for steam generation in boilers, reducing scaling and corrosion. - Food and Beverage Produces distilled water for beverages and helps in waste treatment to maintain quality standards. - Electronics Manufacturing Supplies ultra-pure water for semiconductor fabrication processes, ensuring product reliability.

Conclusion

Industrial RO water systems are a cornerstone of water treatment technologies, helping industries meet their water quality requirements efficiently. The combination of advanced filtration techniques, a detailed process, and reliable components ensures that these systems play a crucial role in supporting production and operational efficiency across various sectors. As water scarcity continues to be a growing issue, the significance of such technologies will only become more pronounced, paving the way for innovations in water purification and sustainability practices.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

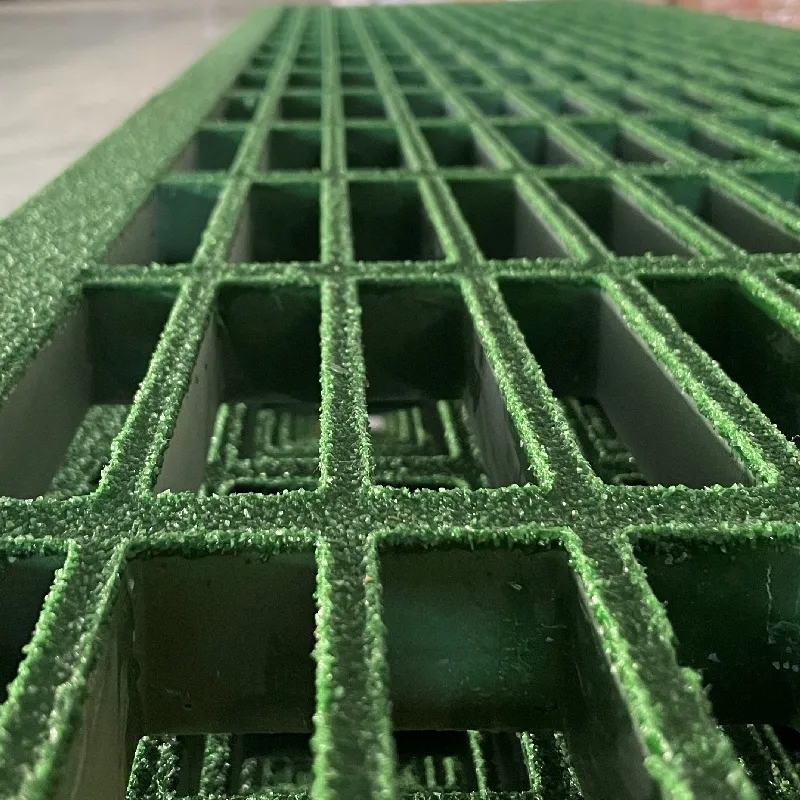

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025