loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

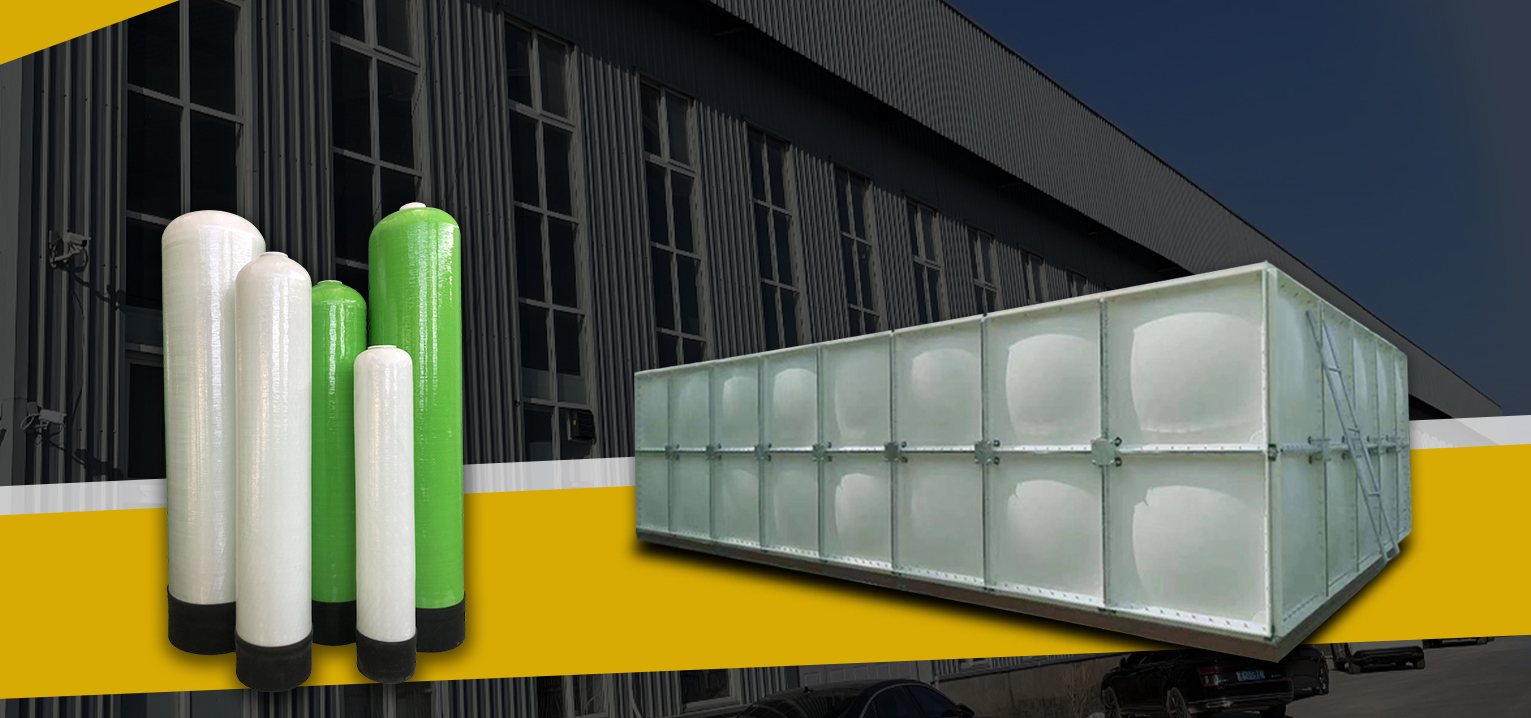

industrial water filter system

Industrial Water Filter Systems Ensuring Clean Water for Optimal Performance

In the manufacturing and industrial sectors, water plays a critical role in various processes. From cooling systems to cleaning equipment, the integral use of water underscores the need for efficient water management practices. One of the essential components of maintaining quality industrial processes is the installation of robust industrial water filter systems. These systems are designed to remove impurities and ensure that the water used in operations meets stringent quality standards.

Industrial water filter systems come in various forms, each tailored to cater to specific needs based on the type of industry and the water contaminants involved. Common filtration methods include mechanical filters, chemical filters, and membrane filtration systems such as reverse osmosis. These technologies work together to eliminate particles, bacteria, sediments, and harmful chemicals from water, ensuring that the water used in production is clean and safe.

The importance of a reliable water filter system in industrial settings cannot be overstated. Contaminated water can lead to significant operational issues, such as equipment failure and reduced product quality. For instance, in cooling systems, the presence of algae or scale can result in heat exchanger inefficiencies, leading to overheating and potential system breakdowns. Similarly, in food and beverage industries, using unfiltered water can compromise product integrity and safety, ultimately affecting consumer health and brand reputation.

industrial water filter system

Cost efficiency is another critical advantage of installing industrial water filter systems. While the initial investment may seem substantial, the long-term savings associated with maintenance, reduced downtime, and improved product quality often outweigh the costs. By preventing scale buildup and corrosion in pipes and machinery, companies can extend the lifespan of their equipment, leading to lower replacement and repair costs.

Moreover, adherence to environmental regulations is a pressing concern for many industries today. Effective water filtration systems contribute to sustainable practices by minimizing wastewater discharge and enhancing water recycling efforts. Many industries are now focusing on closed-loop systems that recycle water for multiple uses. This not only conserves precious resources but also aligns with global sustainability goals, promoting responsible water usage.

Innovation in filtration technology is also rapidly advancing, with the rise of smart water filtration systems. These systems are equipped with sensors and IoT technology that allow for real-time monitoring of water quality, automating the filtration process based on the detected contaminant levels. Such advancements optimize operational efficiency and allow for prompt responsiveness to changing water conditions.

In conclusion, industrial water filter systems are critical for ensuring the smooth operation of industrial processes. By providing clean water, these systems protect equipment, enhance product quality, and support sustainable practices. As industries continue to evolve, investing in advanced water filtration technology will be essential for maintaining operational efficiency and meeting regulatory standards. Ultimately, ensuring access to clean water not only safeguards business interests but also upholds environmental stewardship, paving the way for a cleaner, more sustainable industrial future.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025