loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

High-Quality Covered Grating for Safety and Durability - Direct from FRP Grating Manufacturer

Covered grating, as a critical flooring and walkways component in industrial and civil engineering, has undergone technological leaps over the past decade. With surging industry demands for enhanced corrosion resistance, slip resistance, and cost efficiency, products like Corrosion Resistant and Slip Resistant FRP GRP Fiberglass Covered Grating are increasingly becoming the top choice for sectors such as petrochemical, metallurgy, water treatment, marine, and food & beverage.

Advanced covered grating solutions are mission-critical in highly corrosive and wet conditions.

Advanced covered grating solutions are mission-critical in highly corrosive and wet conditions.

1. Industry Trends & Market Overview

- Global covered grating market size (2023): $1.5 Billion (USD) [(source: MarketsAndMarkets)]

- CAGR (2024-2028): 6.7% driven by demand from water treatment, chemical and offshore platforms

- Top searched related keywords: grating cover, frp grating manufacturer, composite grating, molded grating, walkway flooring.

- Technical advances: Integration of high-performance resins, surface anti-slip coatings, and custom load-bearing designs.

- Standardization: EN ISO 14122-2, ASTM F3059, ANSI A326.3

2. Main Technical Parameters for Covered Grating

| Type | Material | Panel Size (mm) | Load Capacity (kN/m2) | Surface Type | Corrosion Resistance | Slip Resistance (COF) | Certifications |

|---|---|---|---|---|---|---|---|

| Molded FRP Covered Grating | Fiberglass + Resin | 1220x3660, 1000x4000 | 24~66 | Grit/Checker plate | Excellent (ISO 175/ASTM D543) | ≥0.75 (ASTM C1028) | ISO 9001, ASTM, EN 14122 |

| Pultruded FRP Covered Grating | High Content Fiberglass | 1219x3658 | 28~82 | Grit plate/smooth | Superior | ≥0.80 | ISO, SGS |

| Galvanized Steel Grating Cover | Low Carbon Steel | 1000x6000 | 50~150 | Serrated/smooth | Medium/Needs Maintenance | 0.50~0.65 | EN 24530 |

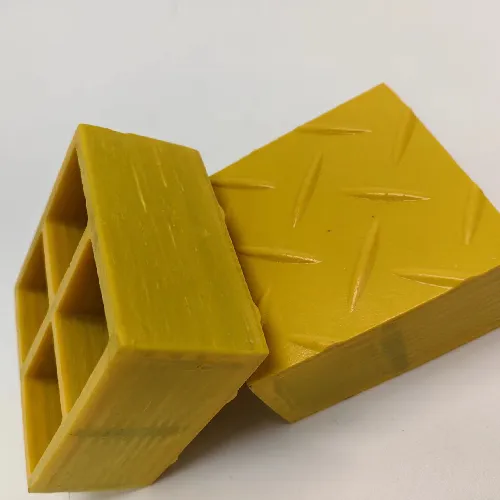

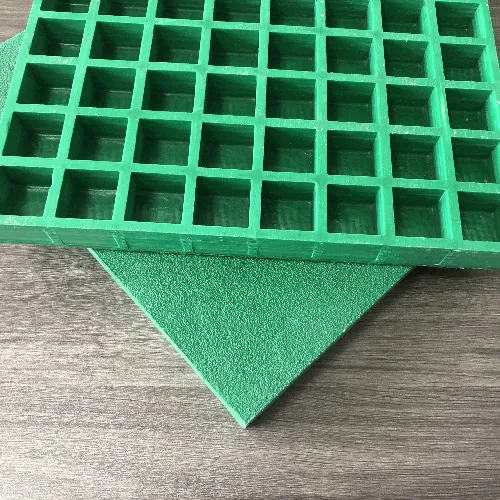

3. Corrosion Resistant and Slip Resistant FRP GRP Fiberglass Covered Grating — Product Process & Technical Superiority

Covered grating from Zhejiang Dingzhi Composite Materials stands out due to advanced craftsmanship, material selection, and rigorous QC. The product features:

- Material: E-glass fiber roving + flame-retardant unsaturated polyester or vinyl ester resin, with an integrally bonded anti-slip cover sheet.

- Manufacturing Process: Precision molding or continuous pultrusion + CNC cover sheet bonding (adhesive, mechanical/multilayer), optional colored top layer.

- Industry Standards: ISO 9001:2015, ASTM D635, ASTM F3059, EN ISO 14122-2.

- Service Life: 20–40 years in pH 1~12 environments. Tested to over 10,000h salt spray (ASTM B117)/UV resistance.

Grating cover– Automated CNC edge-processing ensures tight dimensional tolerances & long-term safety.

Grating cover– Automated CNC edge-processing ensures tight dimensional tolerances & long-term safety.

4. Manufacturer Benchmarking — FRP Grating Manufacturer Landscape

Comparing covered grating suppliers is vital for engineering projects where durability, compliance, and customization are critical. Key factors include material system (resin/glass content), industrial certifications, in-house testing, and project experience.

| Manufacturer | Factory Scale | Main Market | Certifications | Custom Support | On-Site Service Years |

|---|---|---|---|---|---|

| Zhejiang Dingzhi Composites | 48,000 m2 | EU, US, APAC | ISO 9001:2015, SGS, EN | Flexible, CNC/Color/Laser | 23 |

| Fibergrate Composite Structures | 36,000 m2 | Global | UL Classified, DNV | Limited | 40+ |

| MEISER | 52,000 m2 | EU, Africa | ISO, TÜV, EN | Standard | 60+ |

| Strongwell | 42,000 m2 | Global | ISO, ABS-certified | Standard | 65+ |

5. Customization, Delivery, and Quality Guarantees

Today's projects often require covered grating tailored for specific loads, chemical environments, and safety codes. Zhejiang Dingzhi Composites offers:

- Sizing: Customized panels up to 4000mm length, 40–70mm thickness, non-standard shapes (trapezoid/circle).

- Load Class: Light pedestrian (2kN/m²) to industrial heavy traffic (60kN/m²+).

- Resin Type: Orthophthalic, isophthalic, vinyl ester for max. corrosion

- Surface Options: Grit, checker plate, open/closed, color coding (RAL series)

- Logo, pattern, or QR marking via CNC laser engraving

- Delivery: 2–4 weeks (Ex-works, FOB, or DDP incoterms). Expedited grating cover solutions available for urgent shutdowns.

- Warranty: 3–10 years, depending on application and environment

- Support: Full technical datasheet, installation guide, after-sales engineering available in English, Spanish, French, and Chinese.

FRP grating manufacturer customizes solutions for tank farms, water treatment, and offshore walkways.

FRP grating manufacturer customizes solutions for tank farms, water treatment, and offshore walkways.

6. Key Performance Index Comparison – Data Visualization

7. Typical Application Scenarios & Real Customer Experience

- Petrochemical process floors (acid, oil, and flame exposure)

- Wastewater/sewage plants walkways – superior to steel in H2S/Cl- environments

- Marine/offshore platforms, ship decks

- Food processing lines (FDA compliant resins)

- Mining/conveyor covers (anti-slip, anti-static)

- Vessels/chemical tank roofs and trench covers

Challenge: Frequent failure of galvanized grating due to chemical corrosion.

Solution: Switched to covered grating (FRP, anti-slip, closed cover type) from Zhejiang Dingzhi. Annual site audit shows zero incidents and reduced maintenance spend by 63%.

“We have operated for 18 months with no surface delamination or worker slips. Technical support was professional and fast.” — Site Project Lead, Water Utility Shanghai

8. Professional FAQ: Covered Grating Technical Terms

- 1. What is the typical material composition of covered grating?

- High-strength E-glass fiber roving combined with a resin matrix (options: isophthalic polyester, vinyl ester, phenolic). Anti-slip grit is usually embedded during molding for maximum adherence.

- 2. What panel thickness and load classes are available?

-

Standard thickness: 25mm—60mm.

Load classes: A15–F900kN (per EN 1433), ranging from pedestrian traffic to forklift/vehicle grades. - 3. Which industry standards does your grating cover comply with?

- Main compliance: ISO 9001:2015, ASTM F3059, EN ISO 14122-2, UL94 (flame), ASTM C1028 (slip resistance), FDA (food grade on request).

- 4. How is slip resistance tested and quantified?

- By measuring the Coefficient of Friction (COF) with ASTM C1028 and EN 13893, with ≥0.75 considered anti-slip.

- 5. What is the recommended installation method for covered grating?

- Fixing clips (M-type, C-type, L-type), bolting to steel beams, and edge banding for safety. Installation guide and layout drawing are supplied.

- 6. Can the product be used in high-temperature or fire-prone areas?

- Yes, with fire-retardant resin selection and post-cured processing, covered grating passes UL94 V-0 and ASTM E84 Class 1.

- 7. What type of non-destructive testing & QC is performed?

- Visual inspection, barcol hardness, flexural strength (ISO 14125), deflection testing, and UV/salt spray/cold cycling (ISO 4892/ASTM B117).

9. Support, Warranty, Lead Time, and Customer Care

- Technical Documentation: Full datasheets, load tables, CAD drawings, and MSDS available.

- Warranty: 3–10 years (material, performance, and colorfastness, see warranty statement).

- Delivery Time: Standard order: 2–4 weeks; custom-cut: as short as 10 days for repeat customers.

- After-Sales Service: Multilingual engineering team, 48h response, 24/7 emergency replacement support.

- Certifications: All production batches with traceable IDs; routine third-party audit per ISO 9001/EN/SGS/CE.

- Installation Assistance: On-site guidance or video call support upon request.

10. Conclusion and Further References

Covered grating is a rapidly evolving solution for critical flooring and cover needs in industrial, chemical, and public safety sectors. Industry data, field feedback, and technical benchmark prove its superiority in durability, safety, and long-term TCO when compared to steel and aluminum alternatives. To explore further technical papers, market trends, installation best practices, and customer cases, visit the following reputable channels:

- Composites World Magazine – FRP Grating Market Evolution

- Industrial Safety Forum – Best Practices for Grating Covers

- ASTM Technical Papers – ASTM F3059 Standard

- Zhejiang Dingzhi Composites Official Website – Product Specification and Inquiry

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025