loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Durable Steel Grating Solutions for Heavy Load Applications and Industrial Use

Heavy Duty Bar Grating A Comprehensive Overview

Heavy duty bar grating is a vital component used in various industries, known for its strength, durability, and versatility. This type of grating is engineered to withstand high loads and harsh environmental conditions, making it ideal for applications in manufacturing plants, industrial facilities, and infrastructure projects.

What is Heavy Duty Bar Grating?

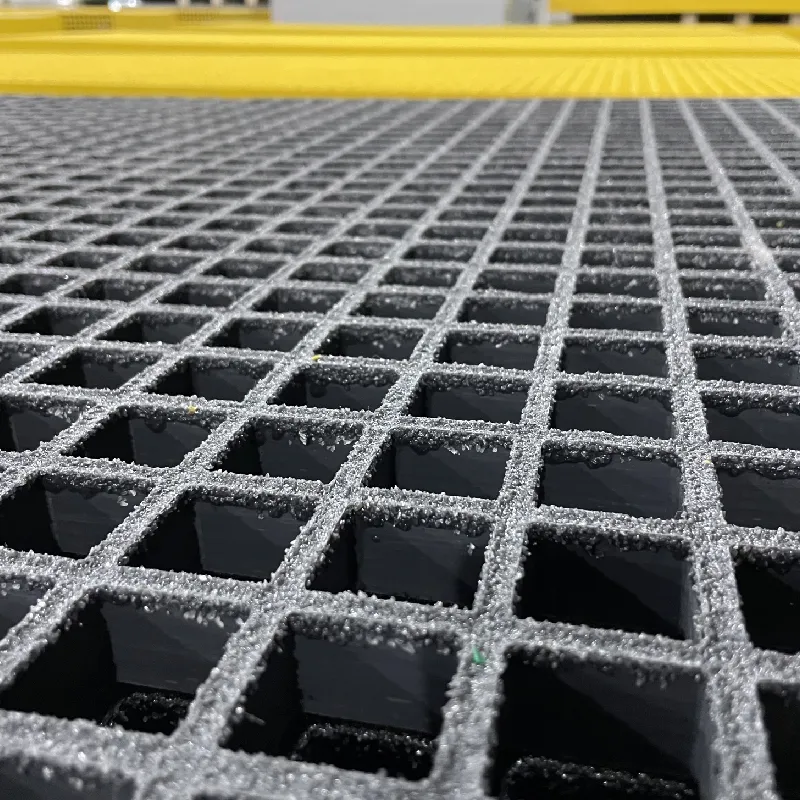

Heavy duty bar grating is a type of flooring solution constructed from solid bars that are welded or clipped together to form a series of load-bearing plates. The bars are typically made from steel, aluminum, or fiberglass, allowing the grating to handle heavy loads while remaining lightweight and easy to install. The spacing between the bars allows for efficient drainage and ventilation, making it suitable for areas where liquids or debris may accumulate.

Materials and Construction

The most common materials used in heavy duty bar grating are galvanized steel, stainless steel, and aluminum. Galvanized steel grating is especially popular due to its excellent resistance to corrosion, making it suitable for outdoor applications. Stainless steel grating, while more expensive, provides enhanced durability and resistance to harsh chemicals, which is essential in food processing and pharmaceutical industries. Aluminum grating is lightweight, corrosion-resistant, and highly versatile, often used in applications where weight is a concern.

The construction of heavy duty bar grating involves the use of load-bearing bars arranged in a specific pattern. Standard bar sizes typically range from 1 inch to 2 inches in height, while the spacing between bars can vary depending on the intended load capacity and application. The load capacity is determined by factors such as the material used, bar size, and spacing, allowing for custom solutions tailored to specific needs.

Applications of Heavy Duty Bar Grating

The versatility of heavy duty bar grating enables its use in a wide range of applications, including

heavy duty bar grating

2. Walkways and Platforms Heavy duty bar grating creates safe walkways in areas where heavy equipment operates, ensuring stability and preventing accidents.

3. Crossover Structures These grating systems can be used to create overhead walkways, allowing workers to navigate industrial environments safely.

4. Trench Covers Heavy duty grating is often used to cover trenches and other access points, ensuring safety while allowing for fluid and debris drainage.

5. Wastewater Treatment Facilities Grating’s ability to resist corrosion makes it ideal for installation in environments exposed to moisture and chemicals.

Benefits of Heavy Duty Bar Grating

One of the main advantages of heavy duty bar grating is its ability to support heavy loads while allowing for high transparency and drainage. This prevents the accumulation of debris and water, reducing maintenance and safety hazards. Its longevity and resistance to environmental factors minimize the need for frequent replacements, providing cost-effective solutions for businesses.

Moreover, the ease of installation and customization options make heavy duty bar grating a preferred choice among engineers and construction professionals. With various finishes and coatings available, these gratings can be adapted to meet aesthetic and functional requirements.

Conclusion

In conclusion, heavy duty bar grating is an essential component in various industries, offering strength, durability, and versatility. Its ability to withstand heavy loads and resist environmental challenges makes it a crucial solution for safe and efficient operations in industrial settings. As industries continue to evolve, the demand for reliable flooring solutions like heavy duty bar grating will only grow, solidifying its importance in modern infrastructure.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025