loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

grp structures

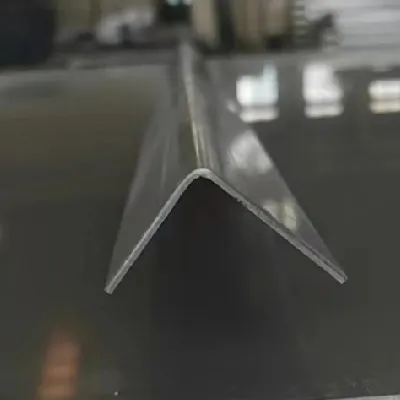

Understanding GRP Structures An Overview of Glass Reinforced Plastic

Glass Reinforced Plastic (GRP), also known as fiberglass, is a composite material that combines a polymer resin with glass fibers to create a versatile and durable product. This innovative material boasts a range of favorable properties, including high strength-to-weight ratio, corrosion resistance, and thermal insulation, making it a popular choice in various engineering and construction applications.

Composition and Manufacturing Process

The key components of GRP structures are the resin and the glass fibers. The resin, typically a thermosetting polymer such as epoxy or polyester, acts as the matrix that binds the glass fibers together, providing structural integrity. The glass fibers, available in various forms such as mats, woven fabrics, or roving, reinforce the resin, significantly enhancing its tensile strength and durability.

The manufacturing process of GRP structures can vary, with methods such as hand lay-up, spray-up, and pultrusion being commonly used. In the hand lay-up process, layers of glass fabric are manually placed into a mold, followed by the application of resin. This method is suitable for producing large and intricate shapes. The spray-up technique involves spraying a mixture of resin and glass fibers into a mold, allowing for quicker production of thicker sections. Pultrusion, on the other hand, is a continuous manufacturing method where glass fibers are pulled through a resin bath and then into a heated die to cure, resulting in long, uniform profiles.

Applications of GRP Structures

GRP structures are employed in a wide range of industries due to their advantageous properties. In the construction sector, GRP is used for items such as roofing panels, stairs, and gratings. Its lightweight nature simplifies transport and installation, while its resistance to chemical corrosion extends the lifespan of structures exposed to harsh environments.

grp structures

In the automotive and aerospace industries, GRP components are favored for their excellent strength-to-weight ratio, enhancing fuel efficiency and performance. For instance, GRP is frequently used in manufacturing body panels, supports, and even structural components of vehicles and aircraft.

Moreover, the marine industry benefits greatly from GRP due to its water-resistant properties. Boats, yachts, and offshore structures frequently utilize GRP materials, which help withstand the rigors of seawater and marine environments, ensuring longevity and performance.

Benefits of GRP Structures

The advantages of GRP structures make them an appealing choice for many applications. Their lightweight nature not only reduces transportation costs but also simplifies handling and installation processes. Additionally, GRP structures are inherently resistant to corrosion, rot, and UV degradation, reducing the need for frequent maintenance and repairs.

Furthermore, GRP possesses excellent thermal and electrical insulating properties, enhancing safety in applications that require such features. The versatility in design allows for the creation of complex shapes that are often difficult or impossible to achieve with traditional materials.

Conclusion

In summary, Glass Reinforced Plastic (GRP) structures represent a significant advancement in material engineering, offering a multitude of benefits across various industries. With their strength, resilience, and adaptability, GRP materials continue to gain popularity as a preferred choice for modern construction and manufacturing needs. As technology progresses, we can anticipate even more innovative applications and improvements in the design and functionality of GRP structures, solidifying their role in future development. The potential for GRP is boundless, transforming the way we think about materials in engineering and design.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025