loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

grp solid top grating

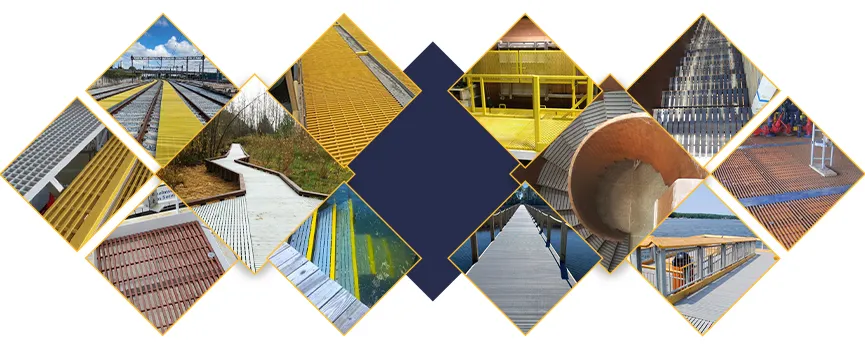

Understanding GRP Solid Top Grating Applications, Benefits, and Specifications

In recent years, the demand for innovative materials in construction and industrial applications has surged. One such material that has gained significant attention is Glass Reinforced Plastic (GRP) solid top grating. This product is renowned for its durability, versatility, and lightweight nature, making it an ideal choice for various applications. This article delves into the principles behind GRP, its benefits, applications, and key specifications.

What is GRP Solid Top Grating?

GRP solid top grating is composed of a composite material where glass fibers are embedded in a resin matrix. This combination gives GRP its remarkable strength-to-weight ratio. The solid top refers to a smooth, non-slip surface, making it ideal for applications where safety and stability are paramount.

Advantages of GRP Solid Top Grating

1. Corrosion Resistance One of the primary benefits of GRP solid top grating is its resistance to corrosion. Unlike traditional metals that rust and degrade over time, GRP maintains its integrity even in harsh environments, making it suitable for industries such as wastewater treatment, chemical processing, and marine applications.

2. Lightweight The lightweight nature of GRP solid top grating simplifies transportation and installation. This is particularly advantageous in construction scenarios where heavy equipment and supports may not be feasible.

3. Durability GRP is designed to withstand high loads and stresses, making it a long-lasting option for flooring, walkways, and platforms. Its resilience ensures that it can endure the rigors of industrial environments without requiring frequent replacements.

4. Safety Features The solid top surface provides excellent grip, reducing the risk of slips and falls. Additionally, GRP grating is available in various designs and colors, enhancing visibility and safety in work areas.

5. Low Maintenance GRP grating does not require regular maintenance, unlike wood, which can rot, or metal, which may require painting and anti-corrosive treatments. This characteristic saves both time and costs for businesses.

Applications of GRP Solid Top Grating

GRP solid top grating is versatile and finds applications across numerous industries, including

grp solid top grating

- Manufacturing Used as flooring in factories, providing a robust surface for heavy machinery and foot traffic while ensuring safety. - Construction Implemented as walkways, access platforms, and stairs, particularly in areas where water accumulation may pose a risk.

- Water Treatment Facilities GRP gratings are often found in these facilities due to their resistance to chemicals and moisture.

- Marine Applications Ideal for docks and piers, GRP’s resistance to saltwater corrosion makes it a preferred choice in the maritime industry.

- Chemical Processing Used in environments where exposure to aggressive chemicals occurs, preserving structural integrity and safety.

Specifications and Considerations

When choosing GRP solid top grating for a specific application, several factors should be considered

- Load Capacity It is essential to determine the maximum load the grating will need to support. GRP grating comes in various thicknesses and designs to accommodate different load requirements.

- Dimensions GRP gratings can be customized in terms of size and configuration to fit the specific needs of a project.

- Color and Finish Depending on the environment, a suitable color can enhance visibility and safety. Anti-slip finishes can also be applied to improve traction further.

- Environmental Resistance Understanding the specific environmental conditions (such as exposure to chemicals, UV rays, or extreme temperatures) helps ensure the selection of appropriate grading.

In conclusion, GRP solid top grating represents a cutting-edge solution for various industrial and commercial applications. Its unique combination of strength, safety, and minimal maintenance makes it an attractive choice for builders and designers seeking reliable and durable materials. Whether used in manufacturing, marine settings, or chemical processing, GRP solid top grating continues to prove its worth in modern construction and industrial practices.

-

Premium FRP Handrail for All ApplicationsNewsAug.29,2025

-

Low Maintenance FRP Mini Mesh Grating ProductsNewsAug.29,2025

-

Innovative FRP Square Tubes for Modern Industrial SolutionsNewsAug.29,2025

-

FRP Water Storage Tanks Wholesale Solutions for Bulk BuyersNewsAug.29,2025

-

FRP Molded Grating Solutions for Diverse Industrial ApplicationsNewsAug.29,2025

-

Construction Advancements Through FRP Pultruded ProfilesNewsAug.29,2025

-

Why Choose FRP Railings, Guardrails, and Handrail Systems?NewsAug.29,2025